PCB Blog

-

PCB Prototypes 3+3 – Manufactured and Assembled

Posted by

–

Read more: PCB Prototypes 3+3 – Manufactured and Assembled

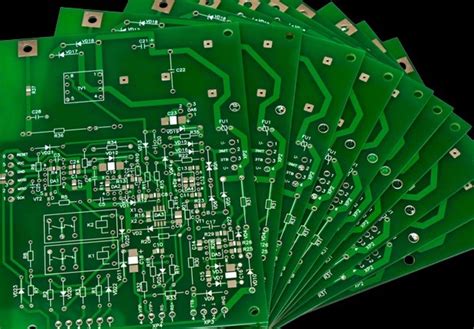

Read more: PCB Prototypes 3+3 – Manufactured and AssembledIntroduction to PCB Prototypes Printed Circuit Board (PCB) prototypes are essential for testing and validating the design of electronic circuits before mass production. PCB Prototyping allows designers to identify and fix any issues in the circuit design, component placement, and functionality. In this article, we will explore the process of […]

-

Where to get a fastest PCB Assembly prototype

Posted by

–

Read more: Where to get a fastest PCB Assembly prototype

Read more: Where to get a fastest PCB Assembly prototypeUnderstanding PCB Prototypes A PCB prototype is an early sample, model or release of a product built to test a concept or process. It allows designers and engineers to explore design alternatives, test theories and confirm performance prior to starting production of a new product. The Importance of PCB Prototypes […]

-

Printed Circuit Board Prototype

Posted by

–

Read more: Printed Circuit Board Prototype

Read more: Printed Circuit Board PrototypeWhat is a PCB Prototype? A printed circuit board (PCB) prototype is an early-stage, physical model of a PCB design used for testing and validation before mass production. PCB Prototypes allow engineers to verify the functionality, performance, and manufacturability of their designs in the real world. Creating PCB prototypes is […]

-

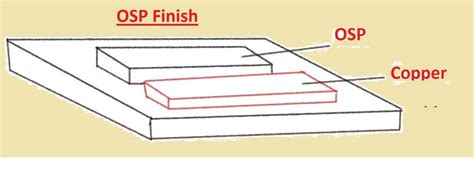

Read more: PCB Prototype Surface Finishes and their types Fruitful Article by RAYPCB

Read more: PCB Prototype Surface Finishes and their types Fruitful Article by RAYPCBIntroduction to PCB Surface Finishes Printed Circuit Boards (PCBs) are essential components in modern electronics, providing a platform for connecting and supporting electronic components. One crucial aspect of PCB manufacturing is the application of surface finishes, which serve various purposes, including protection against oxidation, enhanced solderability, and improved electrical conductivity. […]

-

Try PCB Prototype for Free

Posted by

–

Read more: Try PCB Prototype for Free

Read more: Try PCB Prototype for FreeWhat is a PCB Prototype? A PCB (Printed Circuit Board) prototype is a preliminary version of a printed Circuit Board Designed to test and verify the functionality, performance, and manufacturability of the board before mass production. PCB Prototypes are essential in the electronics industry as they allow engineers and designers […]

-

PCB proto Service Default Values.

Posted by

–

Read more: PCB proto Service Default Values.

Read more: PCB proto Service Default Values.PCB Material and Thickness FR-4 as the Standard Material The most common default material for PCB Prototypes is FR-4, a flame-retardant glass-reinforced epoxy laminate. FR-4 offers excellent mechanical and electrical properties, making it suitable for a wide range of applications. Unless specified otherwise, most PCB Prototyping services will use FR-4 […]

-

Read more: What is the difference between Gerber and Gerber X2 files?

Read more: What is the difference between Gerber and Gerber X2 files?Introduction to Gerber and Gerber X2 Formats Gerber files are widely used in the electronics industry for manufacturing printed circuit boards (PCBs). They contain essential information about the PCB design, including copper layers, solder mask, silkscreen, and drill data. The Gerber format has evolved over time to meet the growing […]

-

Plated Gold Edge Connectors

Posted by

–

Read more: Plated Gold Edge Connectors

Read more: Plated Gold Edge ConnectorsIntroduction to Gold-Plated Connectors Gold-plated connectors are a type of electrical connector that uses a thin layer of gold plating over a base metal, such as copper or brass, to enhance the connector’s performance and durability. The gold plating provides several advantages over non-plated connectors, including improved conductivity, resistance to […]

-

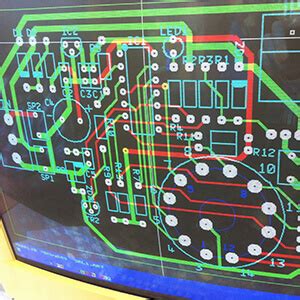

Read more: Component Placement onto the Printed Circuit Board

Read more: Component Placement onto the Printed Circuit BoardIntroduction to PCB Component Placement Printed Circuit Board (PCB) component placement is a crucial step in the PCB Assembly process. It involves strategically positioning electronic components on the board to optimize performance, minimize interference, and facilitate efficient manufacturing. Proper component placement ensures the reliability, functionality, and manufacturability of the final […]

-

Common PCB PCBA Testing Techniques

Posted by

–

Read more: Common PCB PCBA Testing Techniques

Read more: Common PCB PCBA Testing TechniquesIntroduction to PCB Testing Printed Circuit Boards (PCBs) and Printed Circuit Board Assemblies (PCBAs) are essential components in modern electronic devices. To ensure the reliability and functionality of these components, various testing techniques are employed throughout the manufacturing process. In this article, we will explore the common PCB and PCBA […]