HDI PCB Manufacturer

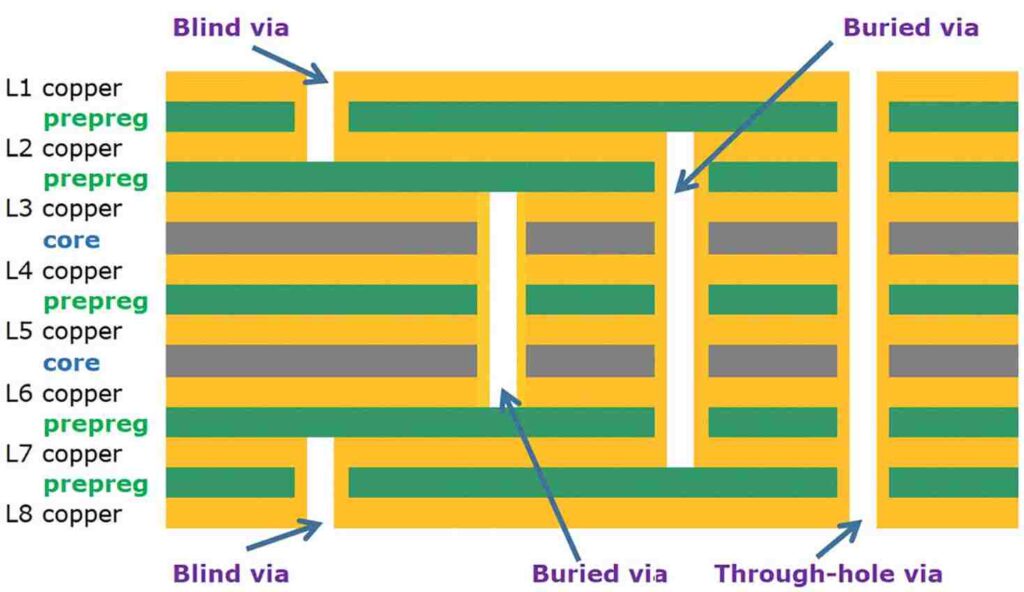

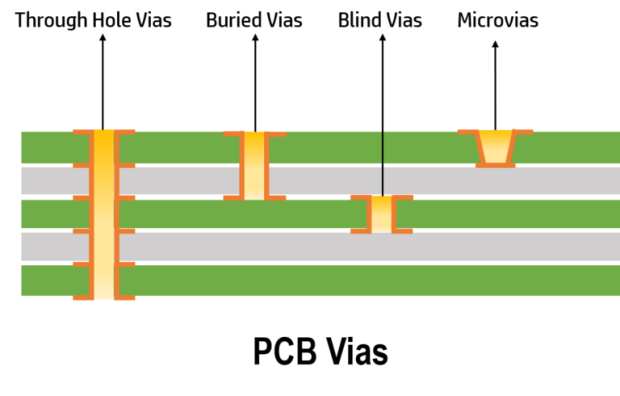

High Quality high-density interconnect PCB Manufacturing, blind via or/and buried hole, accept any layer of the PCB to be interconnected freely.

99.8%

Client retention

100% satisfy clients in our work

18+

Years of experience

Fully focused on HDI PCB manufacturing

1000+

Clients

Solid and responsible technical team

10K+

Project value

99.8% successfully all project done

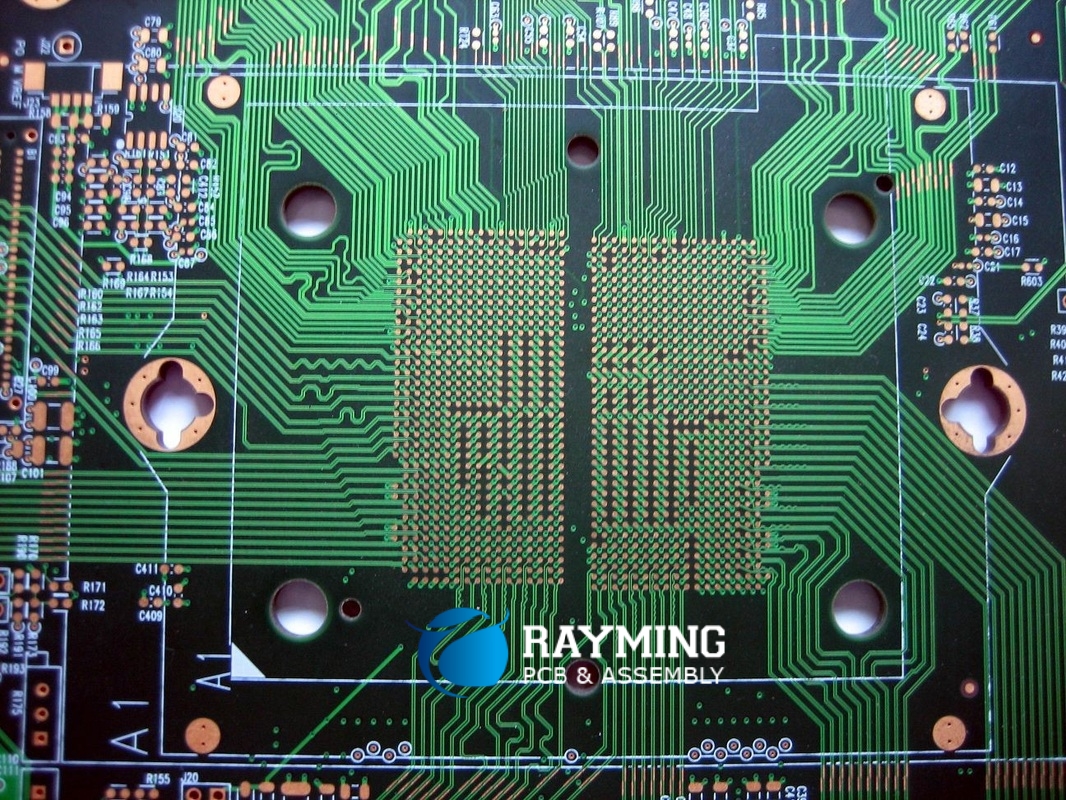

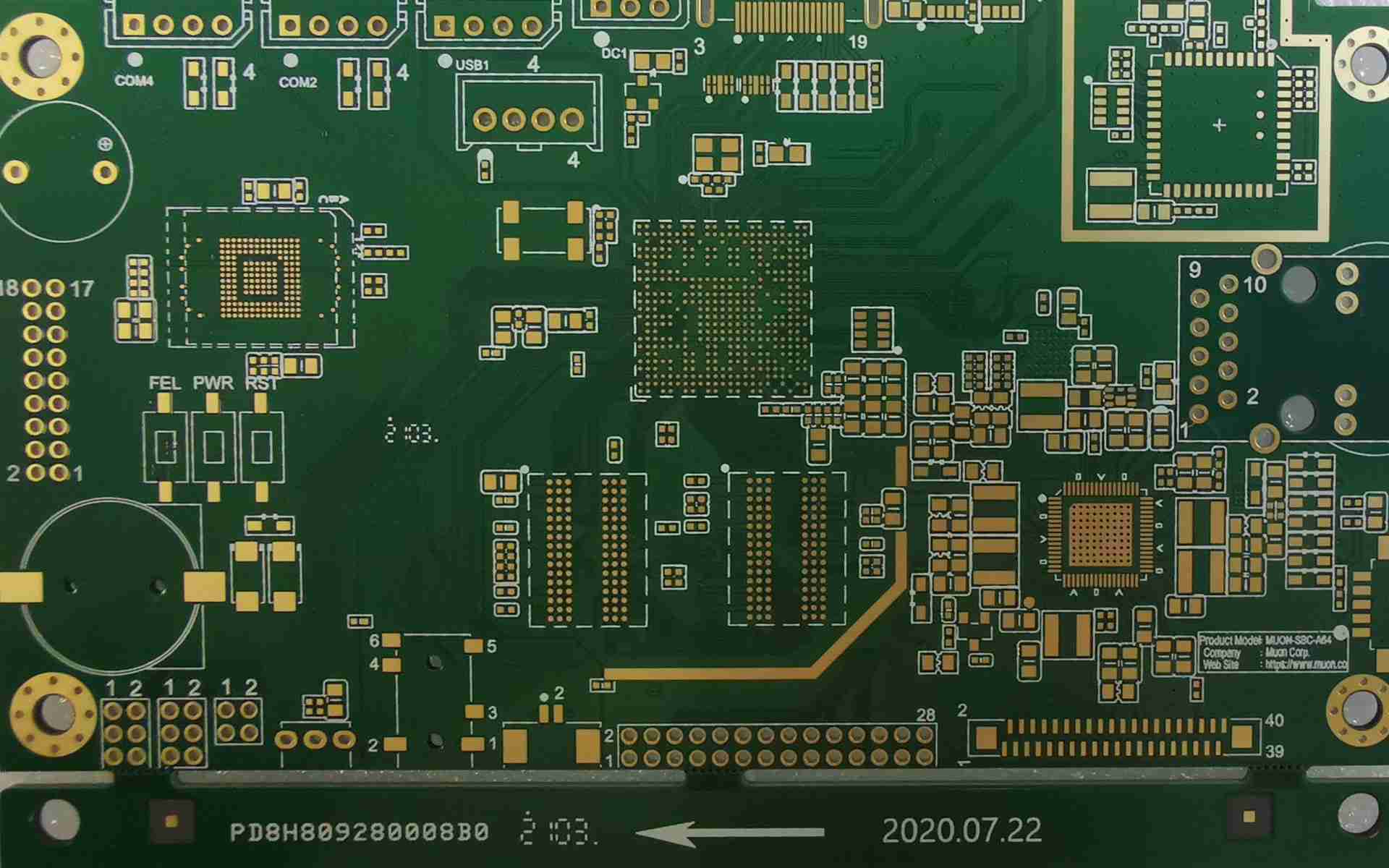

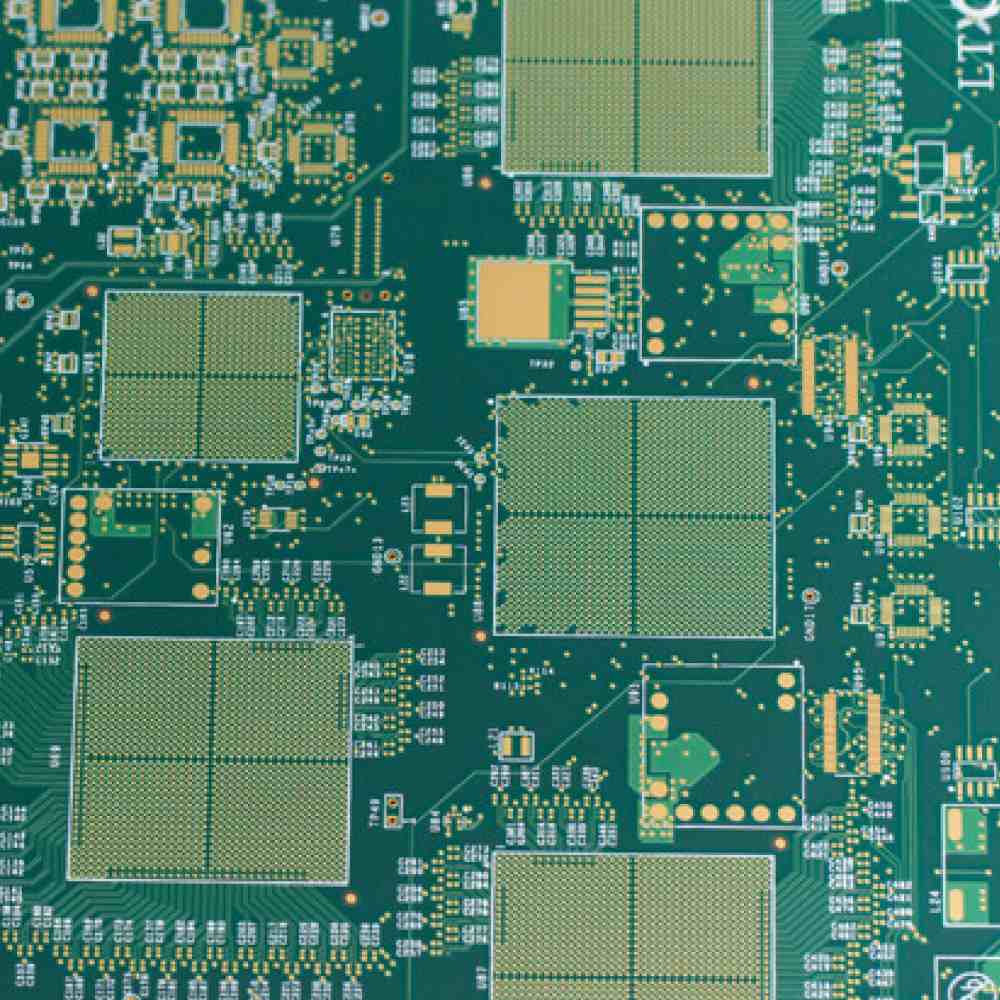

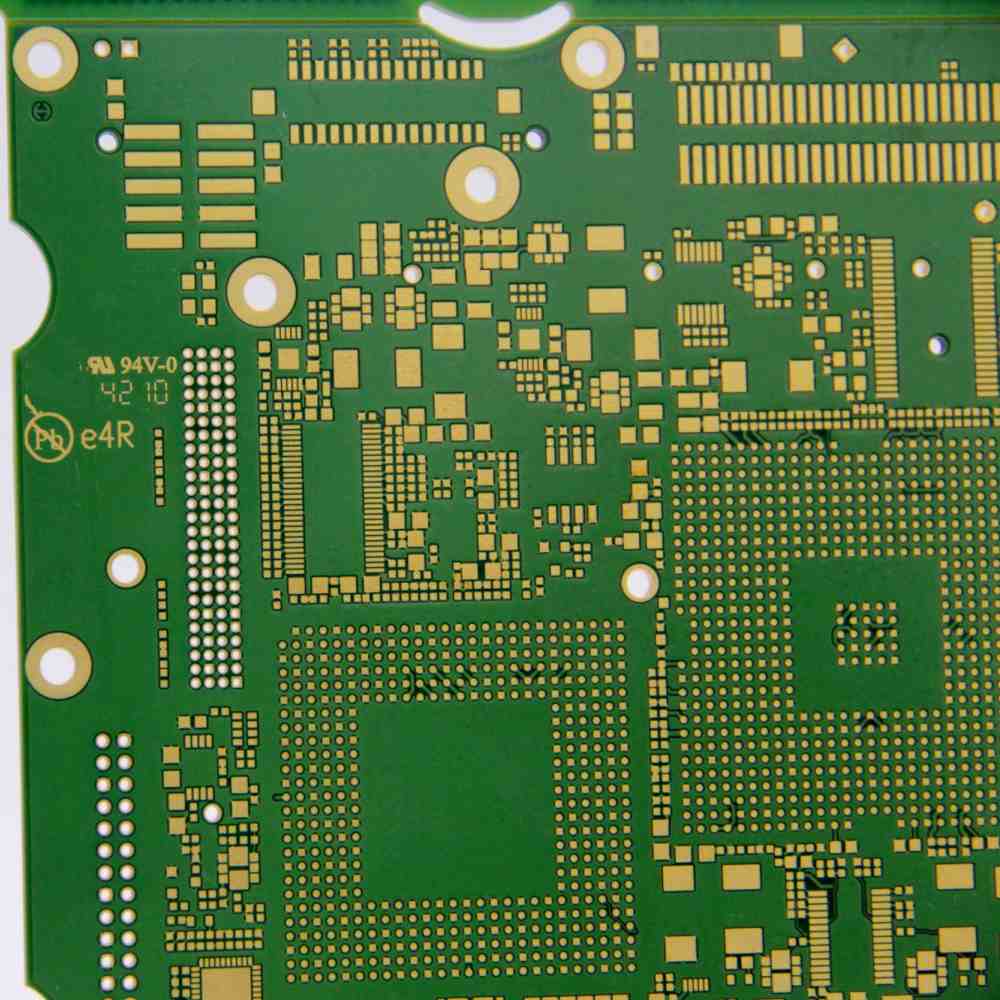

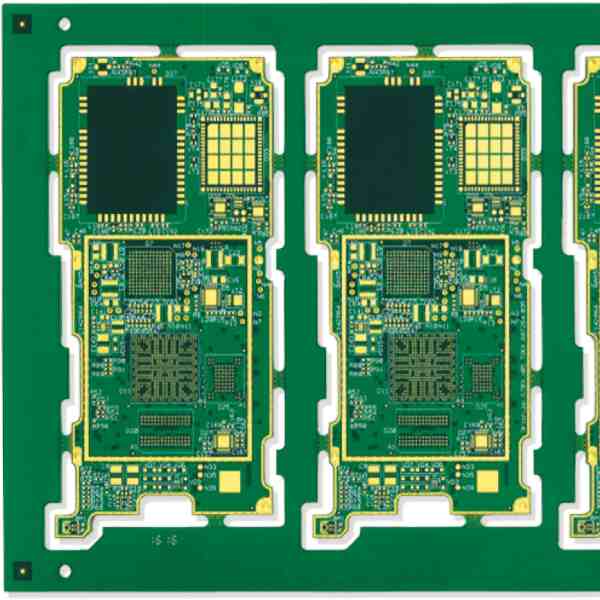

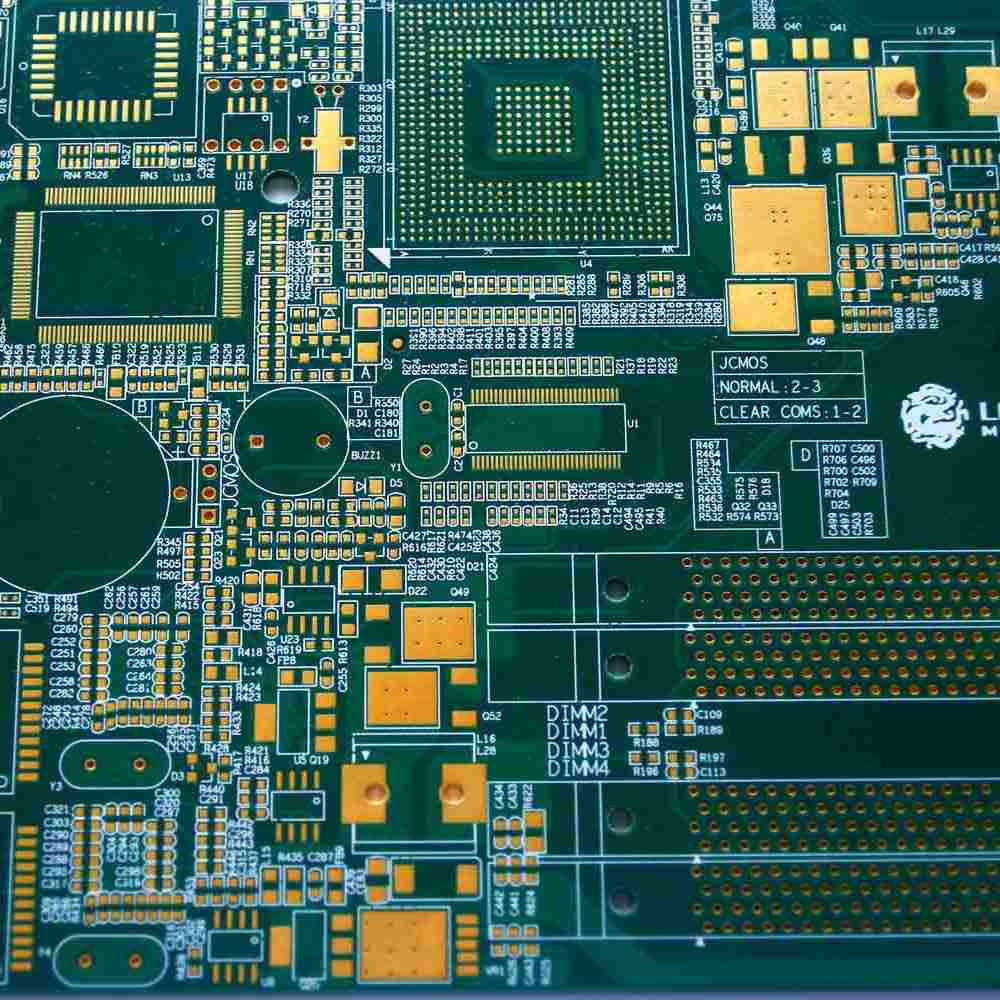

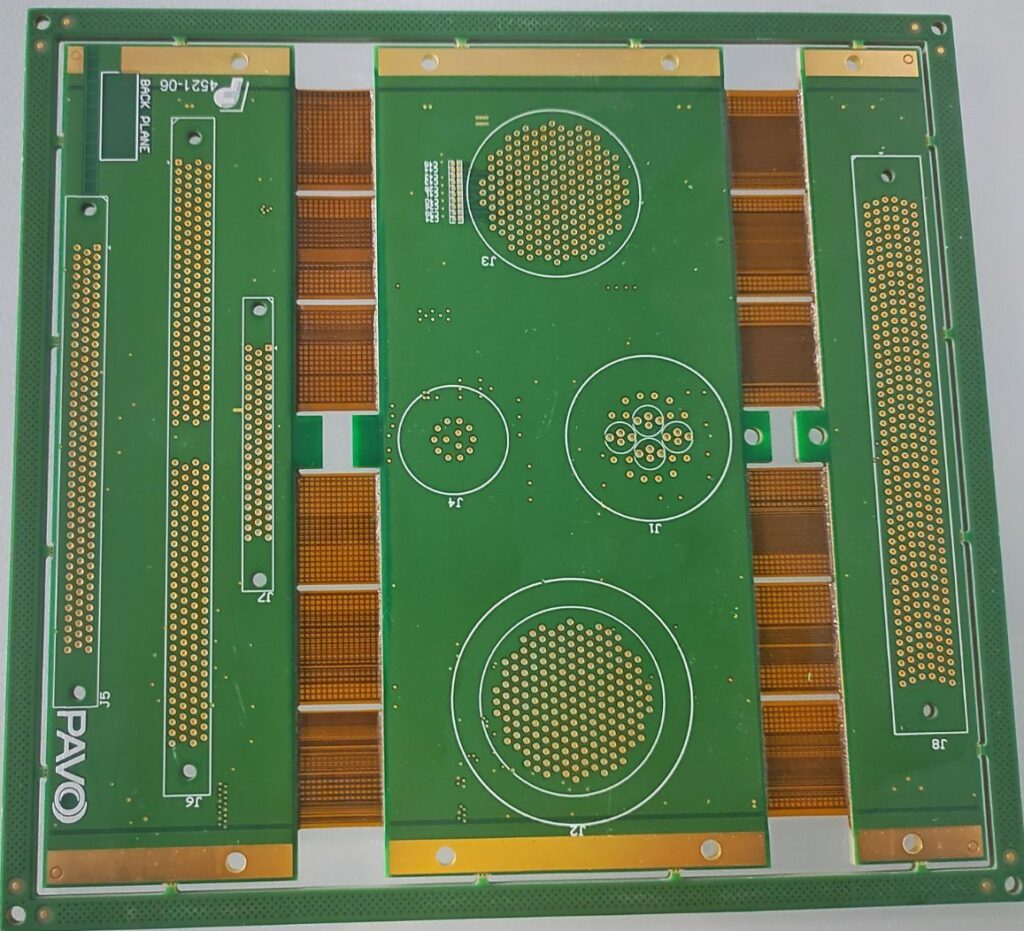

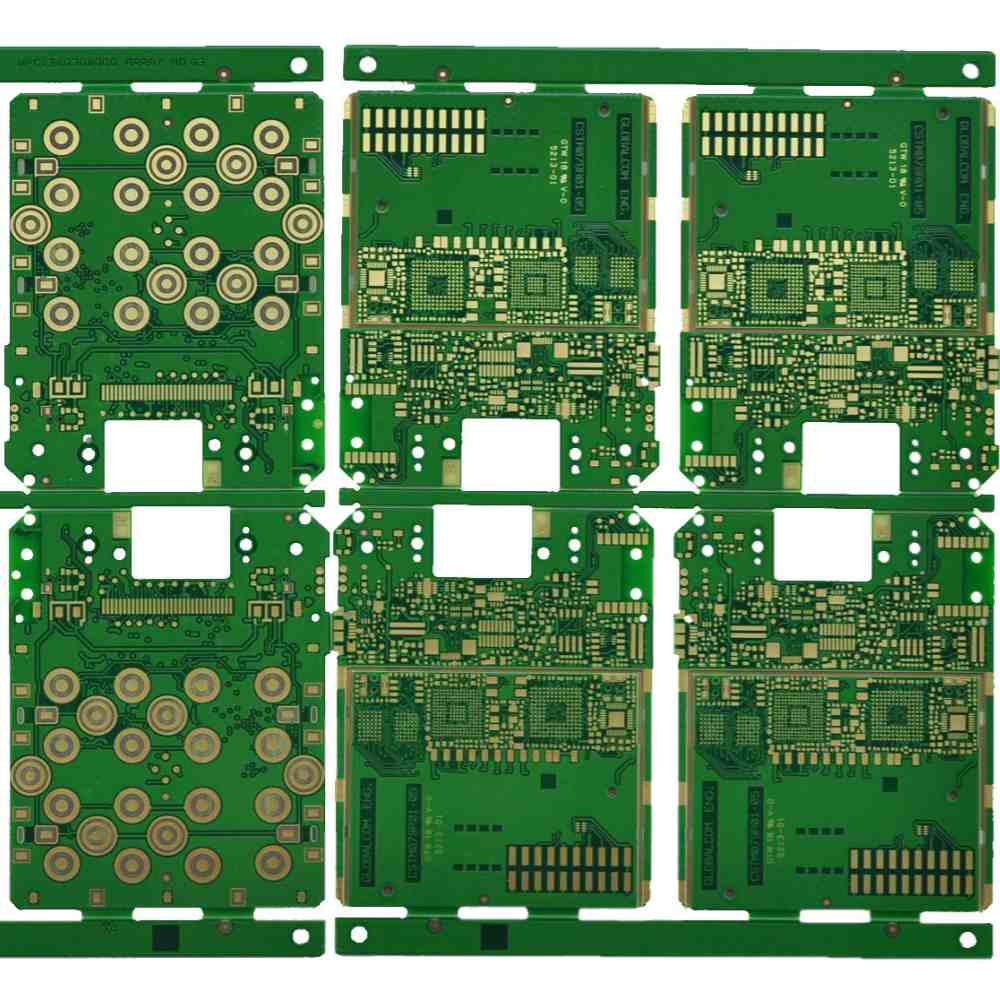

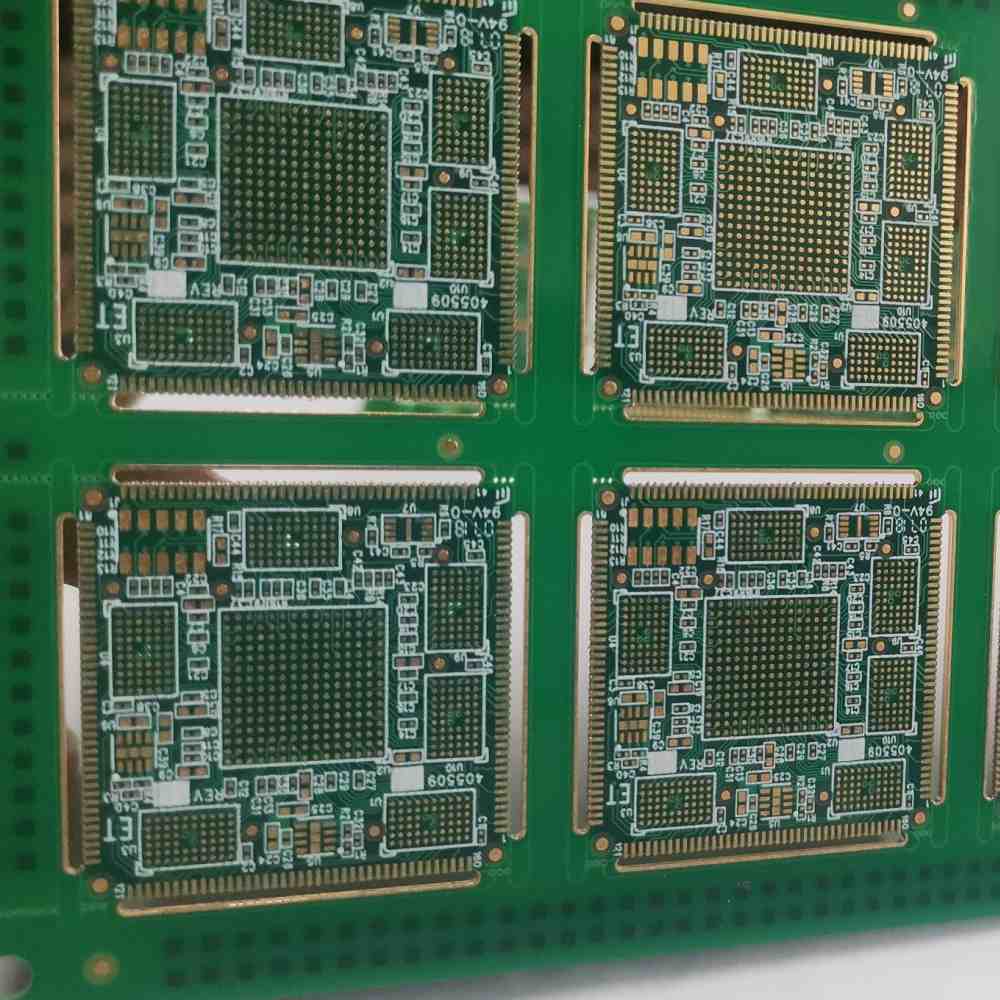

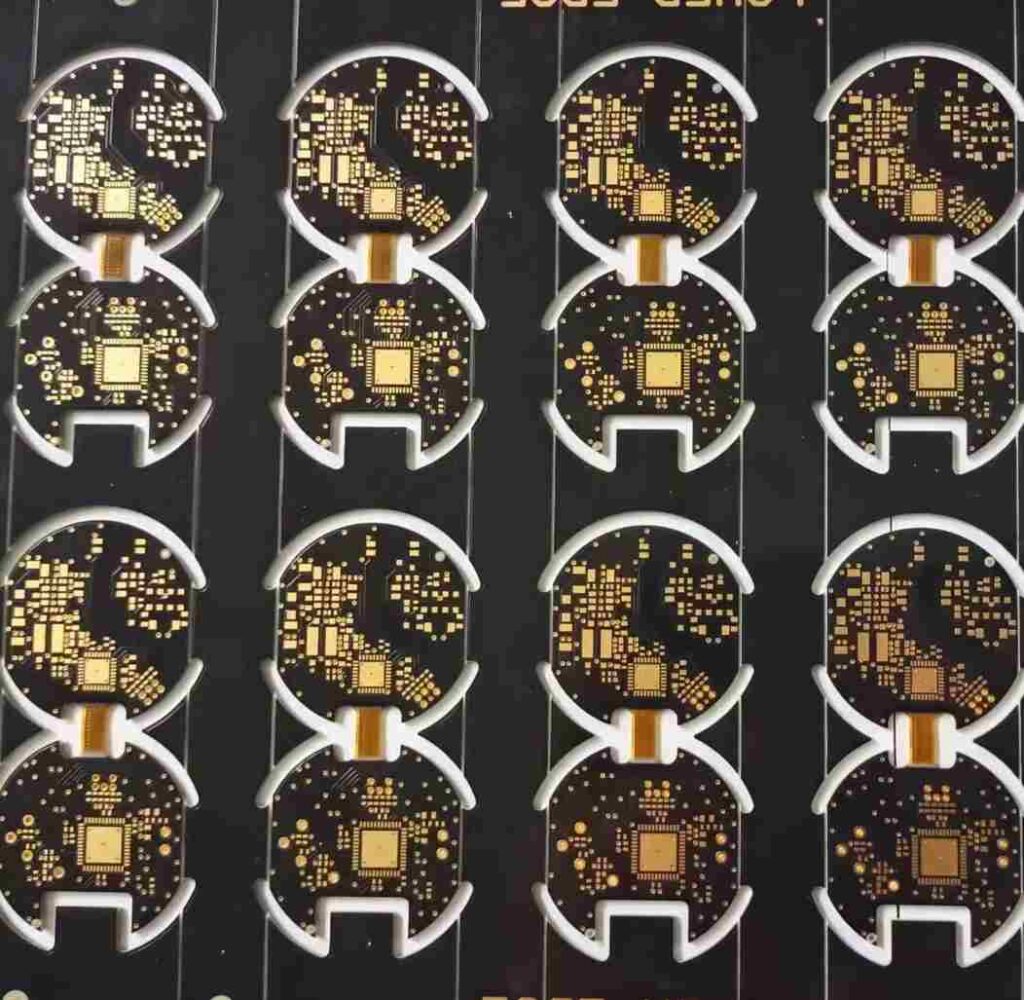

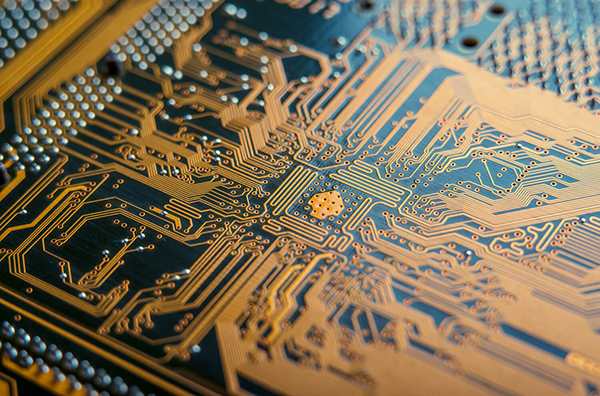

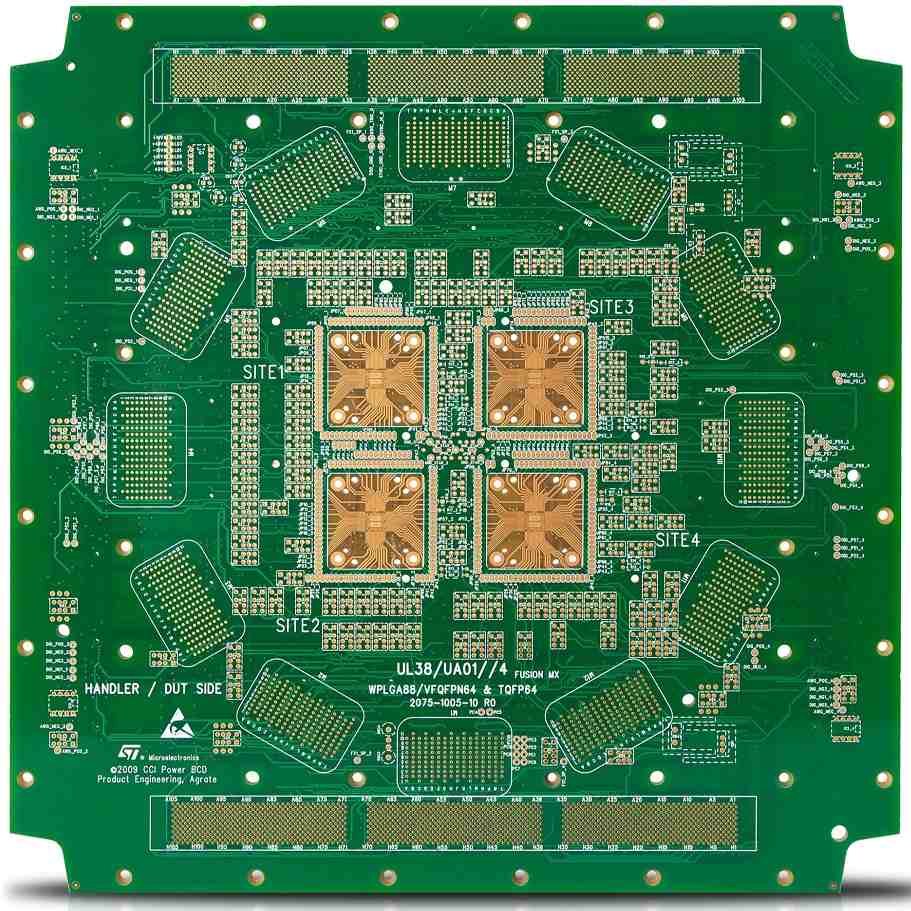

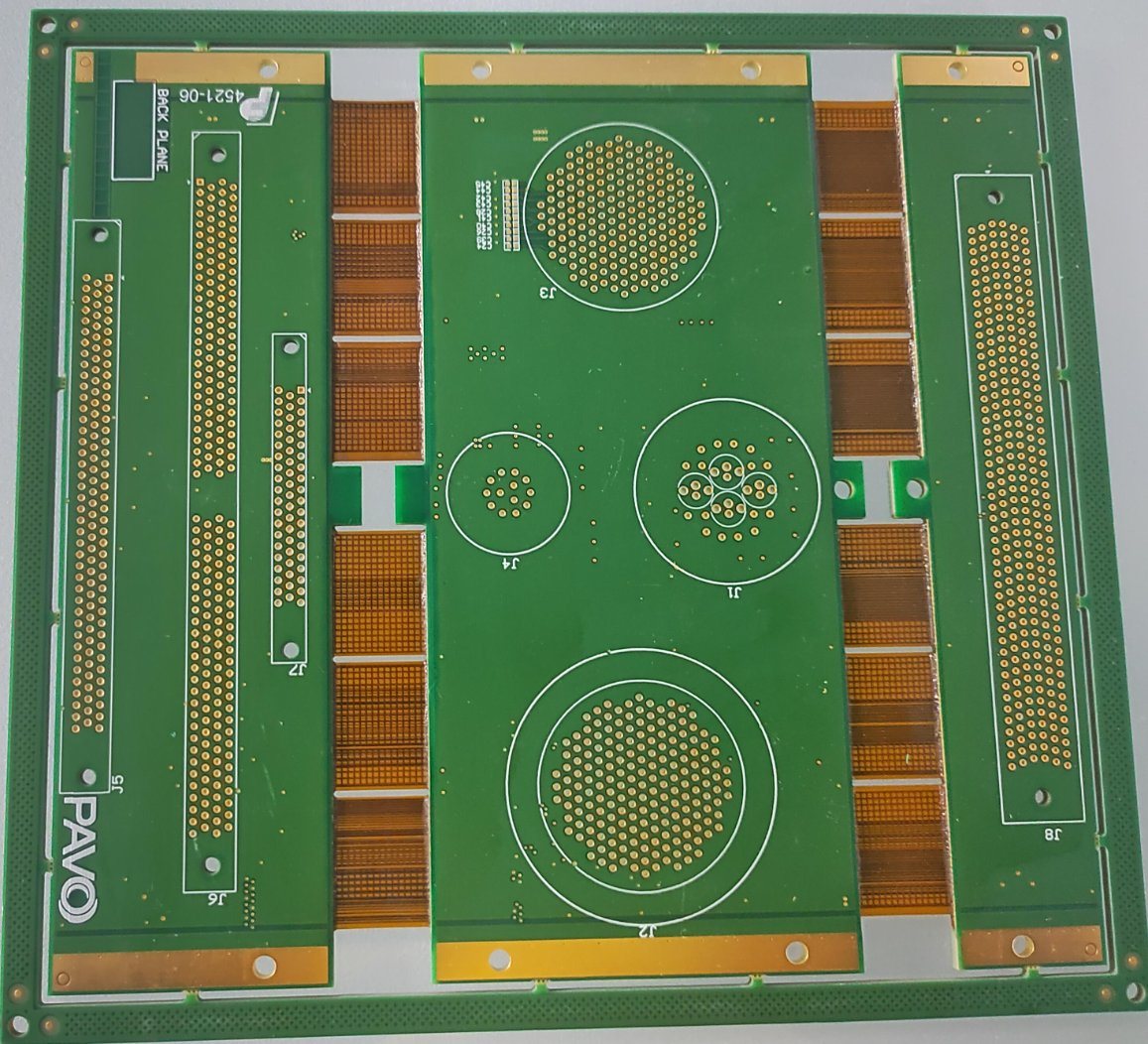

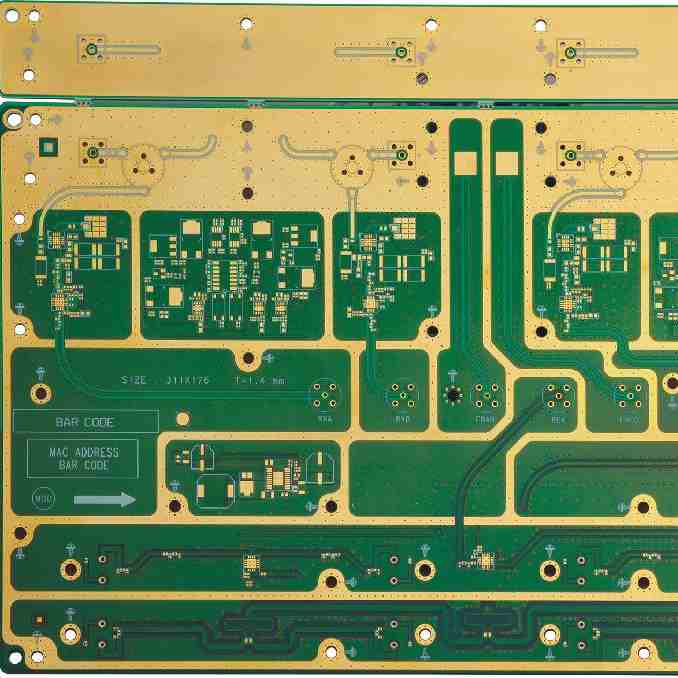

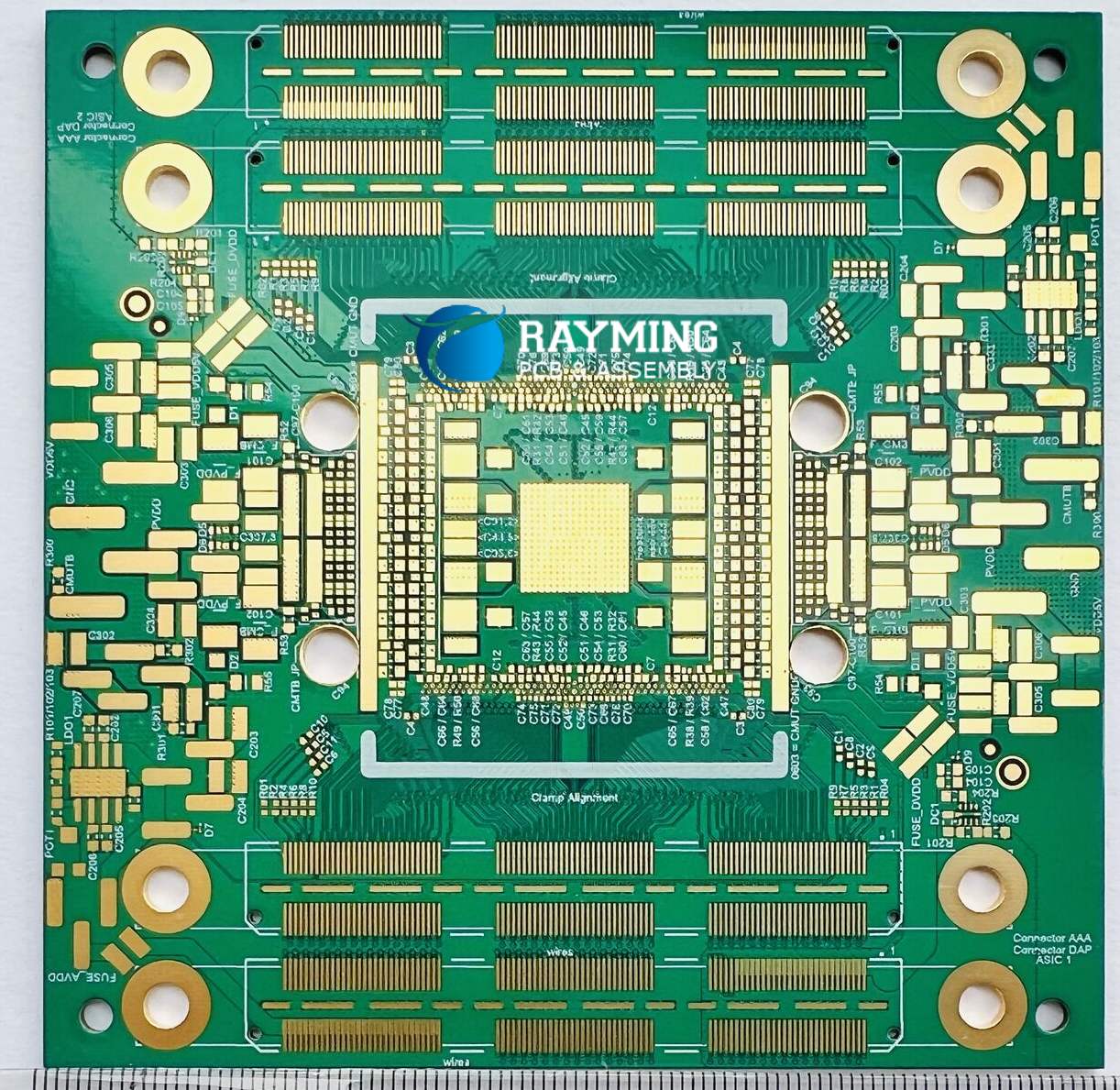

HDI PCB SHOW

HIGH TECH MANUFACTURING

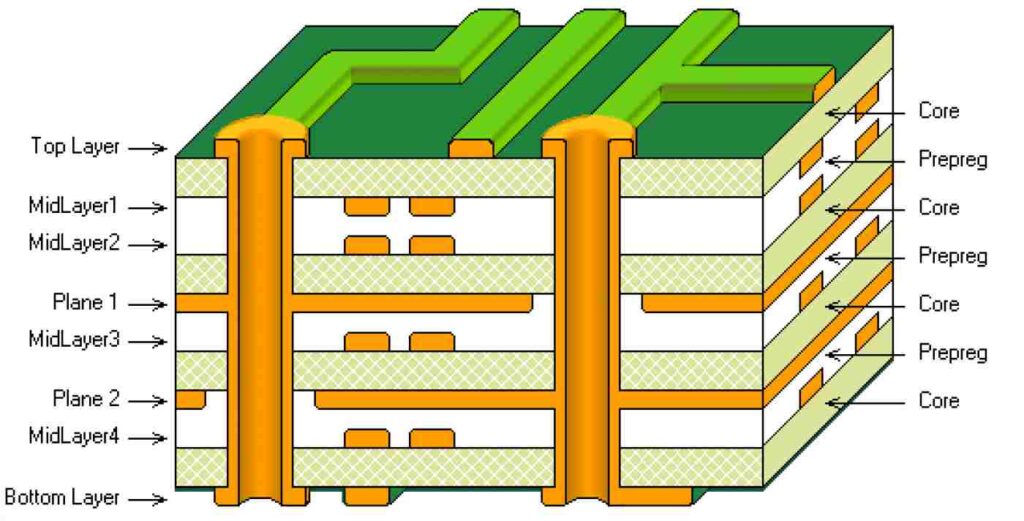

HDI PCB TYPES

HDI PCB (1+N+1)

- This structure of HDI PCB contains 1 “build-up” of high-density interconnection layers, suitable for BGA with lower I/O counts.

- It has fine lines, microvia and registration technologies capable of 0.4 mm ball pitch, excellent mounting stability and reliability, and may contain copper filled via.

- Applications: Cell phone, MP3 Player, GPS, Memory Card.

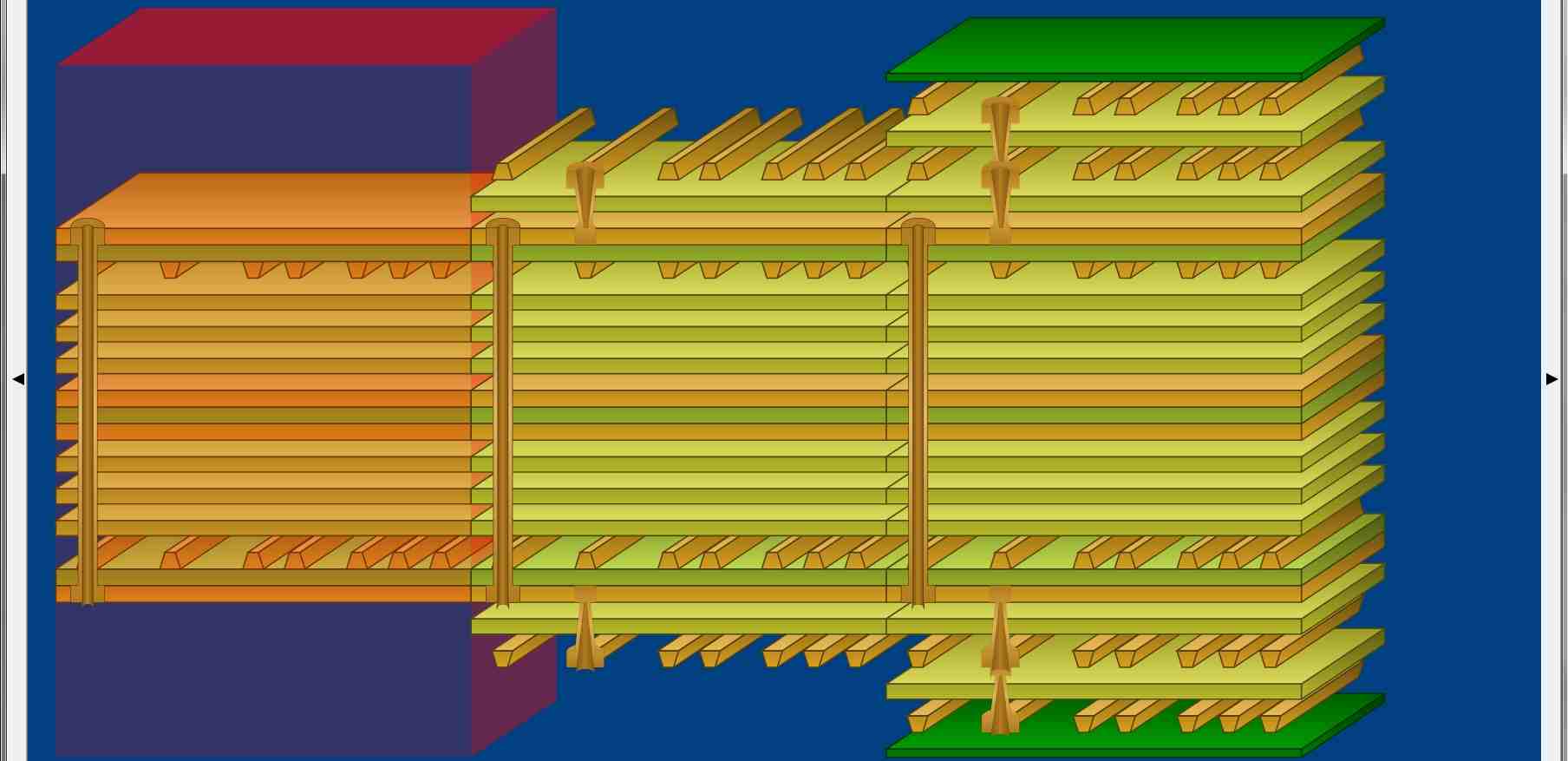

3 Step 3+N+3 HDI

Blind/Buried staggered vias , 8 Layers+ HDI PCB

2 Step 2+N+2 HDI

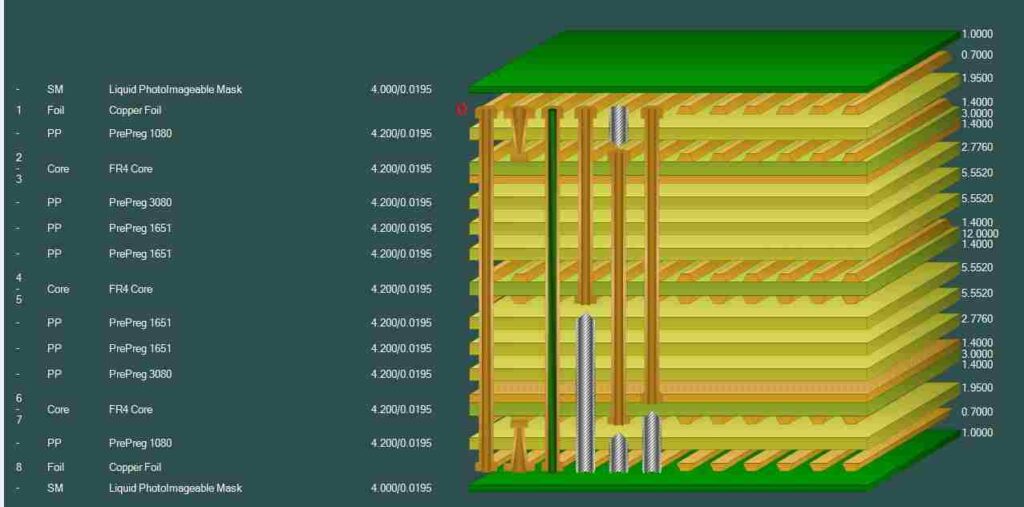

- This structure of HDI PCB contains 2 or more “build-up” of high-density interconnection layers; microvias on different layers can be staggered or stacked; Copper filled stacked microvia structures are commonly seen in challenging designs that demand high level signal transmission performance.

- These are suitable for BGA with smaller ball pitch and higher I/O counts and can be used to increase routing density in a complicated design while maintaining a thin finished board thickness.

- Applications: Cell phone, PDA, game console, portable video recording devices.

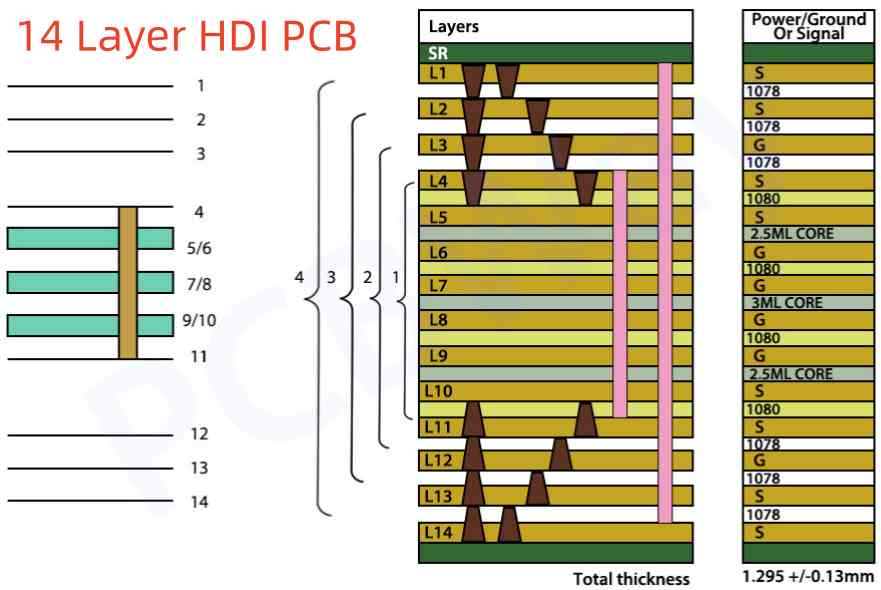

4 Step 4+N+4 HDI

Blind/Buried Vias, 10 Layers+ HDI PCB

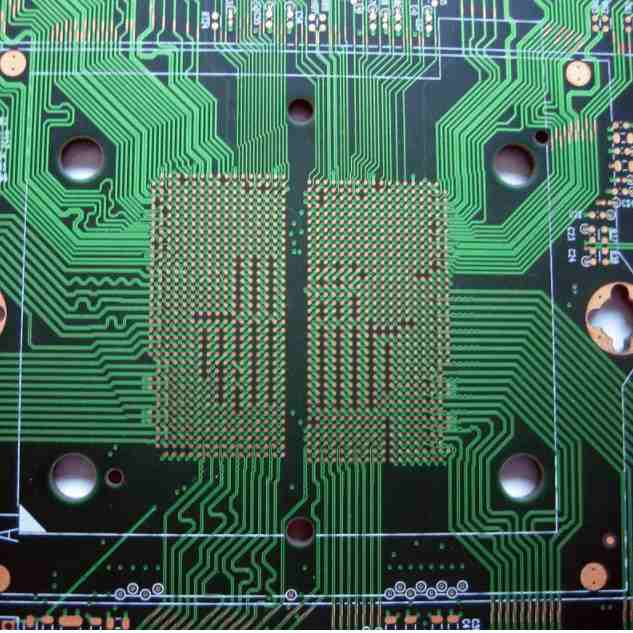

ELIC (Every Layer Interconnection)

- In this HDI PCB structure, all the layers are high-density interconnection layers which allow the conductors on any layer of the PCB to be interconnected freely with copper filled stacked microvia structures.

- This provides a reliable interconnect solution for highly complex large pin-count devices, such as CPU and GPU chips utilized on handheld and mobile devices while producing superior electrical characteristics.

- Applications: Cell phone, ultra-mobile PC, MP3, GPS, Memory cards, small computer devices.

5 Step 5+N+5 HDI

5+N+5 Blind/Buried Vias, 12 Layers+ HDI PCB

Who We Are

We’re HDI PCB Manufacturer.

HDI PCB Manufacturing Capabiltiy : 1+N+1, 2+N+2, 3+N+3,4+N+4, any layer in R&D.

- 2 Step – 2+N+2 Blind/Buried staggered vias

- 3 Step – 3+N+3 Blind/Buried staggered vias

- 4 Step – 4+N+4 Blind/Buried Vias

- 5 Step – 5+N+5 Blind/Buried Vias

What We Do

ELIC HDI PCB Manufacturing

ELIC (Every Layer InterConnect).All the layers of a PCB are high-density interconnection layers, which allows the conductors on any layer of the PCB to be interconnected freely with copper-filled stacked microvia structures (“any layer via”). This provides a reliable interconnect solution for highly complex, large pin count devices, such as central processing unit (CPU) and graphics processing unit (GPU) chips utilized on handheld and mobile devices.

HIGH DENSITY INTERCONNECT PCB

IPC-2226 defines HDI as a printed circuit board with a higher wiring density per unit area than conventional printed circuit boards (PCB). There are different types of HDI features, type I, type II and type III as defined in IPC-2226. In our FAQ you can learn more about the different types.

Complex HDI Projects

Support R&D

HDI ROGERS PCB

rf bOARD

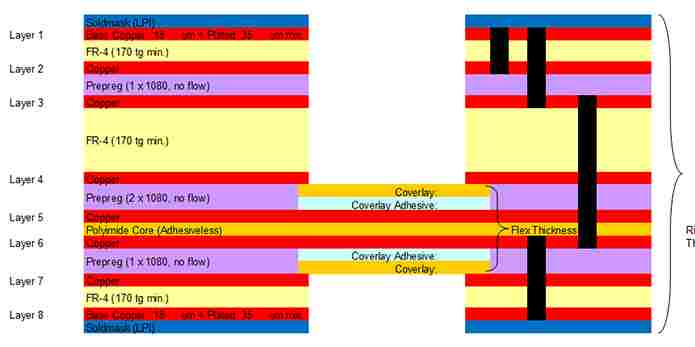

HDI RIGID FLEX

complex

ROGERS+FR4 HDI Board

Hybrid material

ELIC PCB

ANY LAYER HDI

From Our Blog Posts

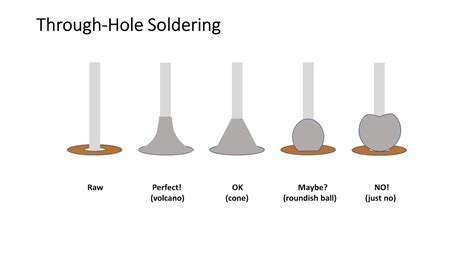

Printed Circuit Board Technology

-

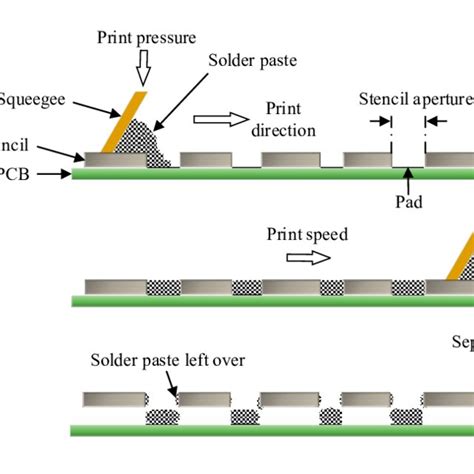

Some Valuable Tips for Solder Paste Printing

Introduction to Solder Paste Printing Solder paste printing is a crucial step in the surface mount technology (SMT) assembly process. It involves depositing solder paste onto the pads of a printed circuit board (PCB) using a stencil. The accuracy and consistency of solder paste printing directly impact the quality and […]

-

Solder and Its Classification

What is Solder? Solder is a metal alloy that typically consists of tin (Sn) and lead (Pb) in varying proportions. The most common solder alloy is Sn63Pb37, which contains 63% tin and 37% lead by weight. However, due to environmental and health concerns associated with lead, lead-free solder alloys have […]

-

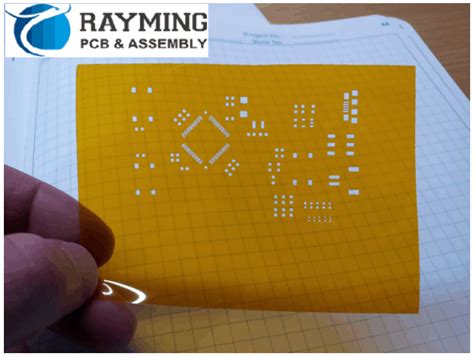

PCB SMT stencil is for accurate solder paste application

What is a Solder Stencil? A solder stencil is a thin, flat sheet of material with precisely cut apertures that correspond to the pads on a PCB where solder paste needs to be applied. The stencil is placed over the PCB, and solder paste is spread across the surface using […]

100%

High Quality

100+

HDI Solution

1,000+

Global Customers

6,000+

Projects

HDI PCB Applications

This is your awesome description

Smartphones and tablets

All smartphones are HDI PCBs with ELIC (Every Layer Interconnection) construction. The HDI PCBs are responsible for creating thinner are smaller portable electronic devices.

Automotive

Car manufacturers are extremely attracted to small-sized PCBs since they can save more space in the car. With the launch of futuristic cars from brands like Tesla, the integration of the electronic devices to provide a better driving experience has been the prime focus of the carmakers

My Feature Title 7

This is a simple description of this feature, just replace with your own content.

Consumer devices

Due to the compact nature, the HDI PCBs are used in most consumer products such as smartphones, tablets, laptop computers, touch screen products and home appliances.

Military and Aerospace

HDI is incorporated in military communications devices and other strategic equipment like missile and defence systems. The HDI PCBs are well suited for extreme environment and hazardous conditions making it ideal for aerospace and military applications.

My Feature Title 8

This is a simple description of this feature, just replace with your own content.

Wearable technology

With the launch of Apple watch and other wearable devices like VR headsets, HDI is becoming the major stakeholder in the consumer market. The wearable technology is gaining popularity among the young crowd due to its exceptional functionality.

Healthcare

The HDI PCB is making an impact on the medical industry. The medical devices are usually HDI since they can fit in small devices like implants and lab and imaging equipment. Medical equipment plays a crucial role in diagnosing diseases and also do provide life support. Ex: Pacemaker, Diagnostic and monitoring facilities.

My Feature Title 9

This is a simple description of this feature, just replace with your own content.

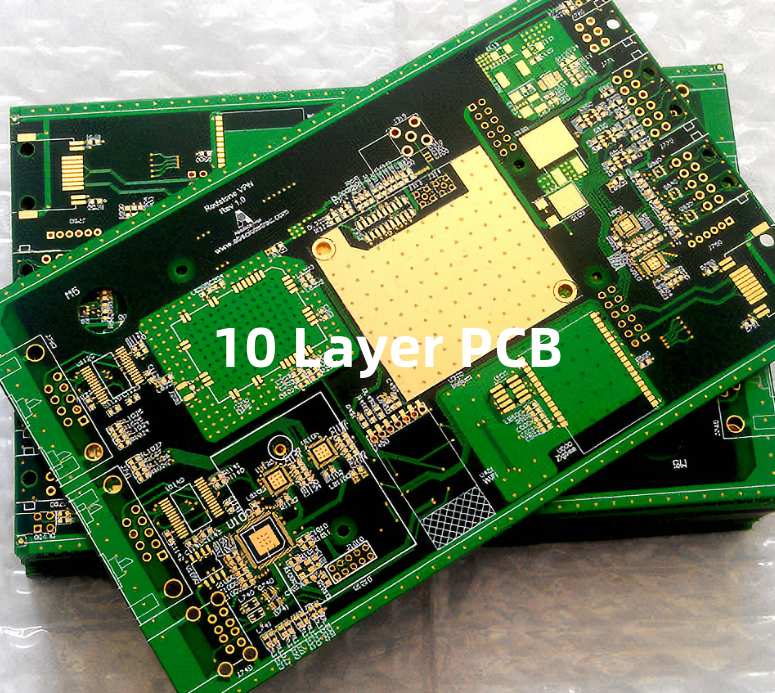

High-Density Interconnect (HDI) Printed Circuit Boards

6 Layer HDI PCB

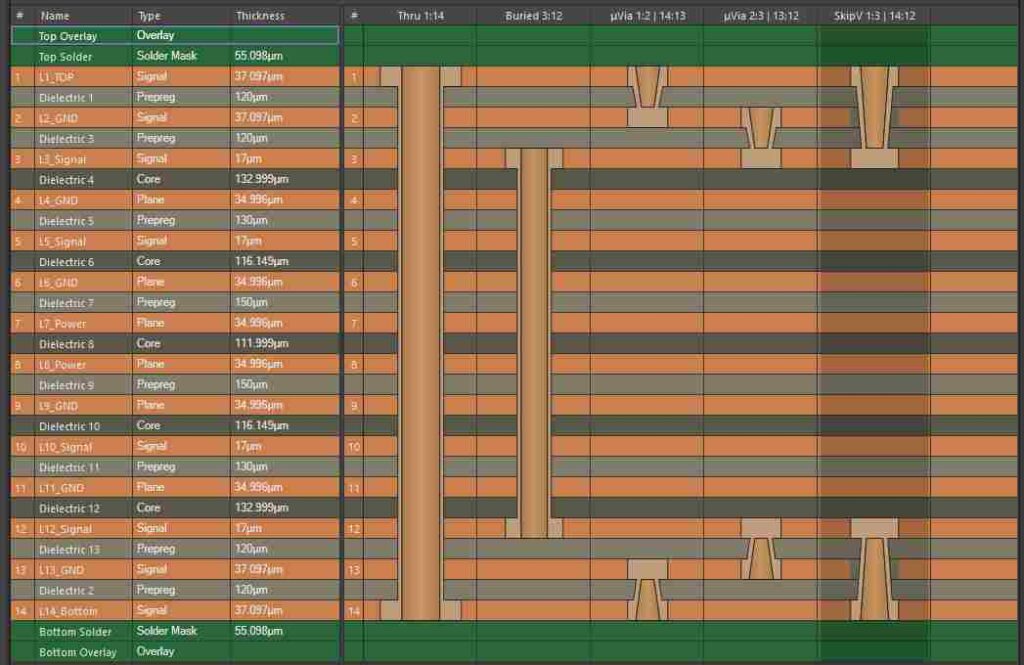

10 Layer HDI PCB