PCB Blog

-

Farnell and RAYPCB collaborate on element14.

Posted by

–

Read more: Farnell and RAYPCB collaborate on element14.

Read more: Farnell and RAYPCB collaborate on element14.Introduction to Farnell and RAYPCB’s collaboration Farnell, a leading global distributor of electronic components, and RAYPCB, a premier PCB manufacturing service provider, have recently announced their collaboration on the element14 platform. This partnership aims to provide customers with a seamless experience in designing, prototyping, and manufacturing high-quality printed circuit boards […]

-

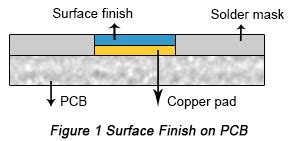

Selecting the Right Surface Finish for your PCB

Posted by

–

Read more: Selecting the Right Surface Finish for your PCB

Read more: Selecting the Right Surface Finish for your PCBWhat is a PCB Surface Finish? A PCB surface finish is a coating applied to the exposed copper traces and pads on a printed circuit board. Its primary purposes are to: – Protect the copper from oxidation and corrosion – Enhance solderability for component assembly – Provide a smooth, level […]

-

How to do PCB Legend Print

Posted by

–

Read more: How to do PCB Legend Print

Read more: How to do PCB Legend PrintWhat is PCB Legend Print? PCB (Printed Circuit Board) legend print, also known as silkscreen printing, is the process of adding text, symbols, and other identifying marks on the surface of a PCB. The legend print serves several purposes, including: Providing component identification and orientation Indicating test points, connectors, and […]

-

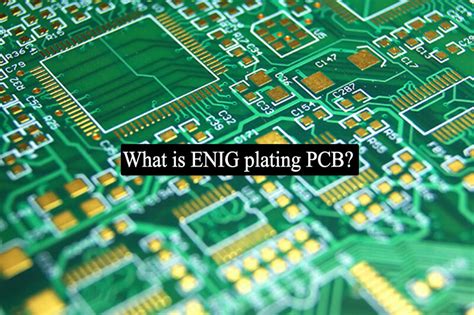

What is Che Ni/Au or ENIG?

Posted by

–

Read more: What is Che Ni/Au or ENIG?

Read more: What is Che Ni/Au or ENIG?What is ENIG? ENIG is a two-step process that involves depositing a layer of nickel on the copper pads of a PCB, followed by a thin layer of gold. The nickel layer serves as a barrier between the copper and the gold, preventing the formation of intermetallic compounds that can […]

-

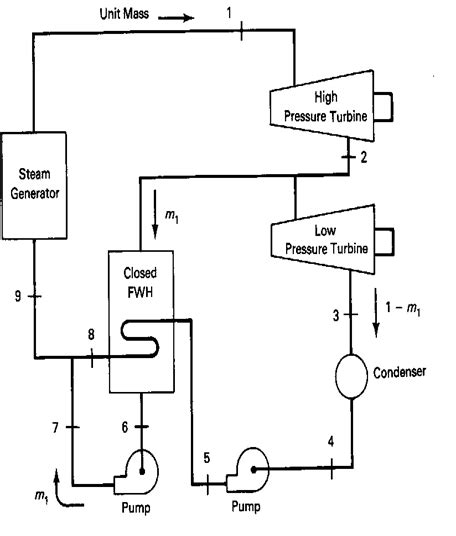

What is the function of Pre-heater

Posted by

–

Read more: What is the function of Pre-heater

Read more: What is the function of Pre-heaterHow Pre-heaters Work Pre-heaters work by transferring heat from a heating medium, such as steam, hot water, or hot oil, to the substance that needs to be heated. The heating medium and the substance to be heated are separated by a heat exchange surface, which allows heat to be transferred […]

-

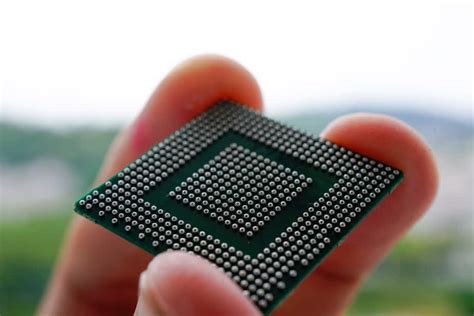

BGA Assembly Capabilities

Posted by

–

Read more: BGA Assembly Capabilities

Read more: BGA Assembly CapabilitiesWhat is BGA Assembly? BGA (Ball Grid Array) assembly is a process of attaching electronic components to a printed circuit board (PCB) using a grid of solder balls underneath the component. This advanced packaging technology allows for high-density interconnections between the component and the PCB, making it ideal for complex, […]

-

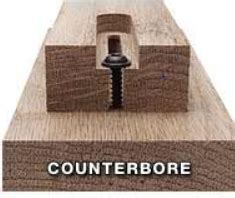

Read more: What is the difference between a countersink and a counterbore in a PCB

Read more: What is the difference between a countersink and a counterbore in a PCBIntroduction to Countersinks and Counterbores in PCBs When designing and manufacturing printed circuit boards (PCBs), it is crucial to understand the various drilling techniques used to create holes for component mounting and interconnections. Two common methods are countersinking and counterboring. Although these terms are often used interchangeably, they refer to […]

-

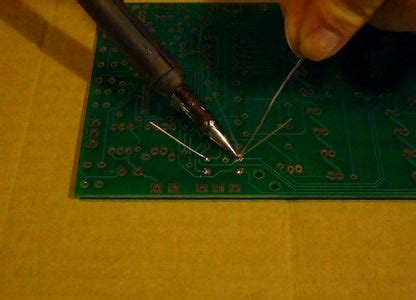

How to Solder a Printed Circuit Board PCB

Posted by

–

Read more: How to Solder a Printed Circuit Board PCB

Read more: How to Solder a Printed Circuit Board PCBIntroduction to PCB Soldering Soldering is an essential skill for anyone working with electronic circuits and printed circuit boards (PCBs). It involves joining two or more metal surfaces together by melting a filler metal (solder) between them. In the context of PCBs, soldering is used to attach electronic components to […]

-

PCB Panelization at Screaming Circuits

Posted by

–

Read more: PCB Panelization at Screaming Circuits

Read more: PCB Panelization at Screaming CircuitsWhat is PCB Panelization? PCB panelization is the process of grouping multiple printed circuit board designs onto a single panel for manufacturing. This technique is widely used in the electronics industry to increase production efficiency and reduce costs. By placing several PCBs on a single panel, manufacturers can produce more […]

-

Software to panelize PCB

Posted by

–

Read more: Software to panelize PCB

Read more: Software to panelize PCBIntroduction to PCB Panelization PCB panelization is the process of arranging multiple printed Circuit Board Designs on a single panel for manufacturing. This technique is commonly used in PCB Fabrication to increase production efficiency and reduce costs. By grouping several PCBs together, manufacturers can optimize material usage, minimize handling, and […]