Introduction

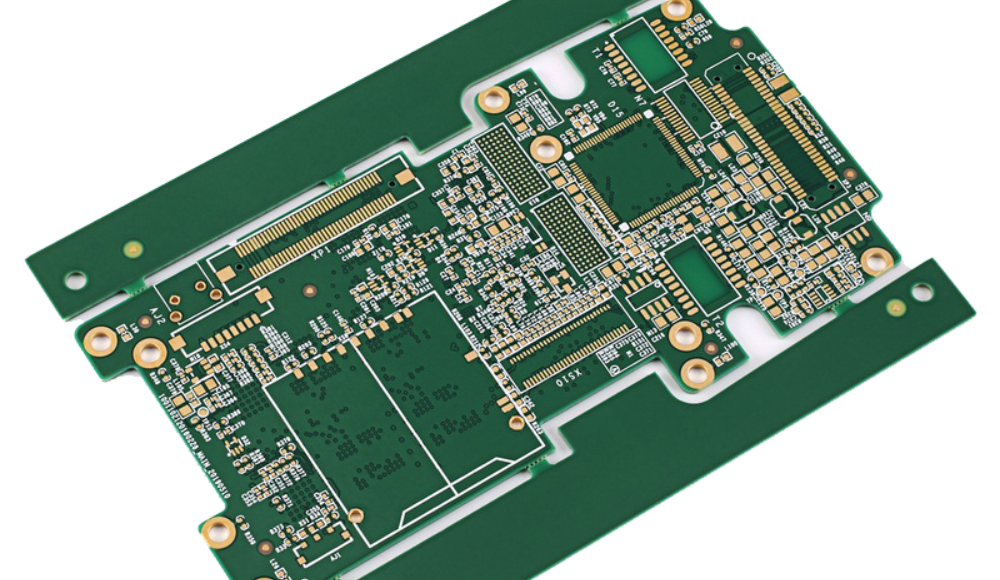

Printed circuit boards (PCBs) are essential components in virtually all modern electronic devices. The PCB manufacturing industry has evolved to meet the growing demand for increasingly complex and compact circuit boards. A key metric for PCB manufacturers is the profit margin, which measures how much profit is made on each circuit board produced. Understanding profit margins allows PCB companies to price their products competitively, manage costs effectively, and maximize earnings. This article will examine the typical profit margins in PCB manufacturing and the key factors that influence profitability.

What is Profit Margin?

Profit margin is a ratio that measures the percentage of revenue retained as profit after accounting for all expenses. It is calculated by dividing net profit by total revenue and expressing the result as a percentage.

Profit Margin = (Net Profit / Total Revenue) x 100

For PCB manufacturers, net profit is the money left after deducting the costs of raw materials, labor, equipment depreciation, utilities, and other production expenses. Total revenue is the amount earned from selling the manufactured PCBs.

A higher profit margin indicates greater efficiency in minimizing costs relative to earnings. It allows more flexibility in pricing products competitively while still generating sufficient income. Most manufacturing industries target profit margins of 10-20%.

Typical Profit Margins in PCB Manufacturing

PCB manufacturing is a complex process requiring substantial investment in facilities, equipment, and skilled labor. As a result, profit margins tend to be lower compared to those in simpler manufacturing operations.

The typical profit margin for a mid-size PCB manufacturer ranges from 8-15%. Very large manufacturers producing multi-layer boards in high volumes can achieve profit margins closer to 20%. On the other hand, smaller prototyping shops may only realize 3-5% margins.

Here are average profit margins broken down across PCB manufacturing types:

- Single-sided boards: 10-12%

- Double-sided boards: 12-15%

- Multilayer boards: 15-18%

- High-density interconnect (HDI) boards: 18-22%

- Flexible circuits: 8-12%

In general, profit margins increase for more complex board fabrication involving greater layer counts and advanced technologies. Manufacturing larger volumes also improves margins through economies of scale.

Key Factors Influencing PCB Profit Margins

Several important factors determine the profitability of a PCB manufacturer:

1. Production Costs

The biggest influence on profit margins is the cost of manufacturing each board. Lower productions costs allow PCB companies to earn larger margins at a given sales price. The main production costs include:

- Raw materials like laminates, prepregs, inks, and metals

- Labor for engineering design, equipment operation, and quality control

- Equipment utilization and maintenance

- Fixed costs like plant rent, utilities, and financing

Efficient manufacturers focuses on optimizing designs to minimize material waste, improving labor productivity, and maximizing equipment uptime to lower per unit costs.

2. PCB Complexity

More complex board designs require more expensive materials, multiple fabrication steps, and lower manufacturing yields. This pushes up per unit costs and squeezes profit margins. Simpler board layouts tend to offer much higher margin opportunities.

3. Volume of Production

Producing higher volumes of a board design allows manufacturers to spread fixed costs over more units, reducing the per unit cost. It also improves labor productivity and machine efficiency. Large production volumes provide economies of scale that enhance margins.

4. Pricing Strategy

A PCB company must be strategic in pricing to hit revenue targets while maintaining attractive margins. Pricing too low leaves money on the table, while pricing too high reduces competitiveness. Smart pricing involves understanding customer cost sensitivity and competitors’ pricing to optimize profitability. Volume discounts and multi-product bundles can also enhance margins.

5. Customer Relationships

Strong long-term relationships with customers allow PCB manufacturers to better forecast demand, plan capacity investments, and reduce sales and admin costs through large repeat orders. The increased business predictability supports higher margins.

How PCB Companies Can Improve Profit Margines

PCB manufacturers can adopt a range of strategies to enhance their profitability:

- Adopt advanced manufacturing technologies – Investments in newer equipment, automation, and smarter processes improve productivity and yields while reducing labor and material costs.

- Offer value-added services – Provide additional services like design, assembly, and testing to earn higher revenues from existing customers.

- Qualify for government incentives – Programs exist to subsidize investment in new equipment, workforce training, and R&D to lower operating costs.

- Outsource commodity boards – Focus internal capacity on higher margin complex boards while outsourcing commodity board production overseas.

- Leverage larger order volumes – Negotiate price breaks from suppliers on larger material volumes to reduce raw material costs.

- Implement lean manufacturing – Reduce work-in-process through detailed production planning, inventory management, and waste reduction.

- Optimize supply chain management – Streamline the sourcing and delivery of materials to minimize inventory holding costs.

With careful management across the business, PCB companies can systematically enhance their profitability over time.

Conclusion

Profit margin is a key indicator of the financial health and earnings potential of a PCB manufacturing business. While margins are constrained by production costs, they can be maximized through efficient processes, strategic pricing, strong customer relationships, advanced technologies, and optimized supply chain management. Typical margins in PCB fabrication range from 8-15%, with more complex boards earning up to 22%. By tracking profitability and implementing improvements, PCB manufacturers can thrive in a very competitive industry.

Frequently Asked Questions

1. What is a good profit margin for a new PCB company?

For a new PCB manufacturer, a good initial target profit margin is 8-12%. This provides room to endure early stage challenges as processes are refined and customers are acquired. Once established, the business can target 10-15% margins.

2. How can PCB manufacturers increase profit margins?

Common ways PCB companies enhance profit margins include improving designs to reduce material waste, investing in automation, qualifying for government incentives, outsourcing commodity production, leveraging larger material volumes, and streamlining operations through lean manufacturing principles.

3. Do PCB manufacturers make high profit margins?

PCB manufacturing profit margins are generally on the lower side compared to other industries, averaging around 8-15%. Margins tend to be constrained by high equipment costs, technology investments, competitive pressures, and labour-intensive processes. However, larger manufacturers can achieve 15-20% margins with economies of scale.

4. What factors reduce profit margins for PCB manufacturers?

Major factors that squeeze PCB profit margins include rising material and labor costs, producng lower volumes, manufacturing simpler boards, inefficient processes, underutilized capacity, excessive scrap/rework, and outdated equipment. Maintaining competitiveness requires minimizing these margin impacts.

5 What are the most profitable types of PCBs to manufacture?

Complex multilayer boards, HDI boards, and flexible PCBs offer the highest profit margins, typically 15-22%. They require advanced processes and expensive materials, but the technical expertise needed to fabricate them successfully allows for stronger profitability. Commodity single or double layer boards have lower margins around 8-12%.

Leave a Reply