Introduction

The Taconic RF 35 is an important radio frequency (RF) laminate material that is widely used in the production of high frequency circuit boards and RF systems. In this article, we will provide a comprehensive overview of this versatile material, including its key properties, manufacturing process, applications, and frequently asked questions.

What is Taconic RF 35?

Taconic RF 35 is a PTFE (Polytetrafluoroethylene) based woven glass reinforced microwave laminate material manufactured by Taconic. It has a dielectric constant of 3.5 and is designed for optimal high frequency performance. Some key features of Taconic RF 35 include:

- Excellent dielectric constant stability over frequency

- Low loss for high frequency applications

- Tight dielectric constant tolerance (±0.05)

- Low Z-axis expansion

- Good thermal conductivity

- UL 94V-0 flammability rating

With its precise dielectric properties and thermal stability, Taconic RF 35 allows circuit designers to maintain critical impedance control and consistent performance across operating temperatures. This makes it well-suited for designing high reliability RF circuits and systems.

Manufacturing Process

Taconic RF 35 starts with PTFE resin that is blended with a reinforcing glass microfiber woven fabric. This prepreg material is then laminated using proprietary techniques to achieve the target dielectric thickness and properties. The laminates are then fully cured in a multi-zoned oven before being calibrated for dielectric constant consistency and drilled or routed into circuit boards.

Some key aspects of the Taconic RF 35 manufacturing process include:

- Tight web tension control during lamination to minimize skew/stress

- Precise temperature and pressure control during lamination

- Post-lamination annealing to remove internal stresses

- 100% dielectric QC testing on finished laminate

This meticulous process control allows Taconic to produce RF 35 laminates with industryleading consistency and performance tolerances.

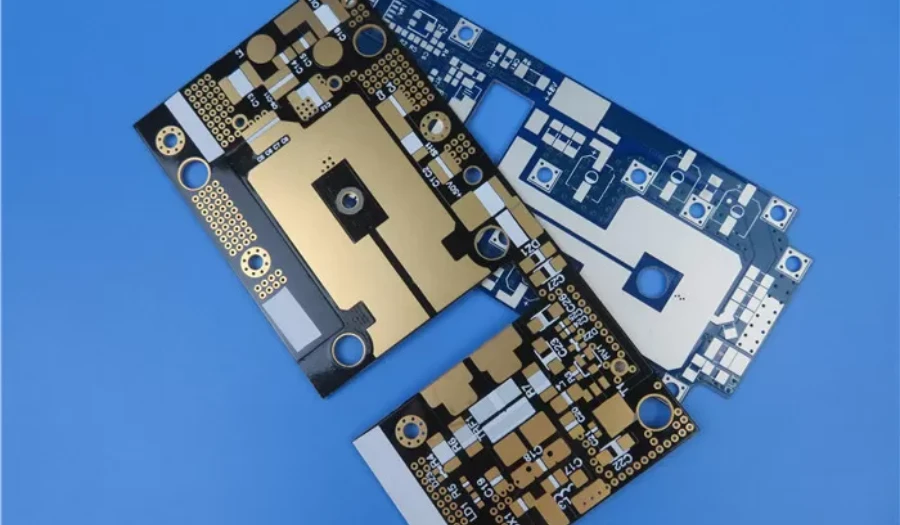

Applications

Thanks to its stable and low-loss dielectric properties, Taconic RF 35 is an ideal choice for a wide variety of RF, microwave, and millimeter wave applications including:

- Satellite communications

- Radar and defense electronics

- Test and measurement equipment

- 5G cellular infrastructure

- Automotive radars

- Aerospace and aviation electronics

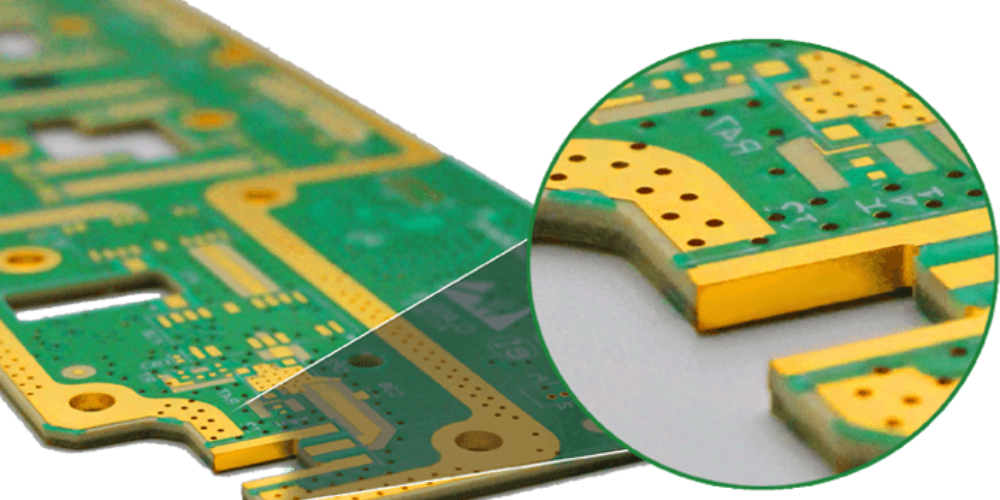

It is used to fabricate boards for frequency-sensitive circuits such as filters, mixers, antenna elements, amplifiers, oscillators, and more. The consistent Q values and low Z-axis expansion also make it suitable for multilayer RF circuit boards.

Some common applications of Taconic RF 35 laminates include:

Wireless Infrastructure

- Base station antennas

- Remote radio heads (RRH)

- Small cell boards

Aerospace and Defense

- Phased array radars

- Electronic warfare systems

- Satellite payloads

Automotive

- 77 GHz radars

- 24 GHz radars

- V2X communications

RF 35 Material Properties

Here are some of the key material properties that make Taconic RF 35 an ideal choice for high frequency and microwave applications:

| Property | Value |

|---|---|

| Dielectric Constant | 3.5 ± 0.05 |

| Loss Tangent | 0.0019 |

| TCE (XY) | 13 ppm/°C |

| TCE (Z) | 47 ppm/°C |

| Thermal Conductivity | 0.71 W/m/K |

| Dielectric Strength | >1.5 x 106 V/m |

| Surface Resistivity | 1 x 1014 ohm/sq min |

| Volume Resistivity | 1 x 1016 ohm-cm min |

| Water Absorption | <0.02% |

| TG | >280°C |

| Flammability Rating | UL 94 V-0 |

As evident from the table, it provides a stable dielectric constant over frequency with low loss, excellent thermal performance, and UL flammability compliance – making it ideal for high reliability RF designs.

Availability

Taconic RF 35 laminates are available in a variety of standard and custom sheet sizes and thicknesses. Standard sheets are available in thickness ranging from 0.005” to 0.125” and panel sizes up to 18” x 26”.The laminates can also be supplied with rolled copper foil (1/2 oz to 3 oz) for fabricating printed circuit boards.

For high volume applications, Taconic also offers RF 35 in panel sizes up to 48” x 96” through its partnership with TUC Inc. This allows larger boards to be fabricated for applications like antenna arrays and satellite subsystems. Custom requirements for dielectric thickness, copper weights, and panel sizes can also be supported through Taconic’s in-house lamination and fabrication capabilities.

FAQ

Here are answers to some frequently asked questions about Taconic RF 35 laminates:

Q: What is the shelf life of RF 35 material?

A: Taconic RF 35 laminates have an indefinite shelf life when stored in a ambient conditions away from direct sunlight. The dielectric properties remain stable over time.

Q: Can RF 35 be used for multilayer boards?

A: Yes, RF 35 is an excellent material for fabricating multilayer boards using PTFE composite materials as bonding sheets. The low Z-axis expansion provides reliable plated through hole reliability.

Q: What are the typical RF design values used for RF 35 material?

A: Most designers use the following RF material properties for circuit modeling:

- Dielectric Constant (Dk): 3.5

- Loss Tangent (Df): 0.0019

- Conductor Bulk Resistivity: 4.5 x 10-6 ohm-cm

Q: What is the CTE and Tg of RF 35 laminates?

A: The coefficient of thermal expansion (CTE) is 13 ppm/°C in X-Y direction and 47 ppm/°C in Z direction. The glass transition temperature (Tg) is > 280°C.

Q: Can RF 35 material be machined using standard FR-4 processes?

A: Yes, RF 35 laminates can be readily machined and processed using traditional FR-4 circuit board fabrication techniques like drilling, routing, punching and v-scoring. No special tools or processes are required.

Leave a Reply