<h2>Overview of SCC PCB Manufacturer</h2>

SCC stands for Surface Circuits Corporation, a leading printed circuit board (PCB) manufacturer located in [city, state]. Founded in [year], SCC has over [number] years of experience in PCB fabrication and assembly. They utilize state-of-the-art equipment and cutting-edge technologies to produce top-quality boards for various industries including automotive, aerospace, telecommunications, medical, and more.

Some key capabilities of SCC PCB manufacturer include:

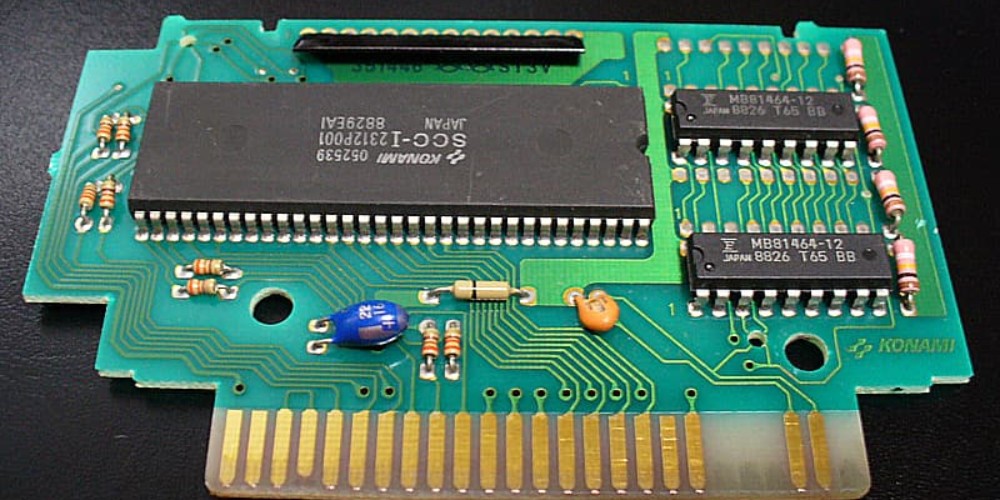

- Multi-layer PCBs with up to [number] layers

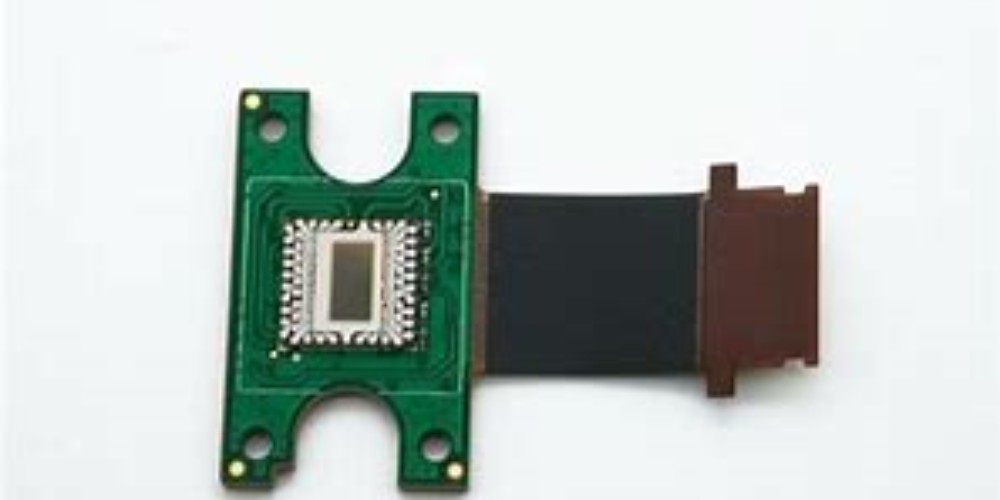

- High-density interconnect (HDI) PCBs

- Flexible and rigid-flex PCBs

- Quick turnaround prototyping

- RoHS compliant manufacturing

<h2>SCC PCB Manufacturing Process</h2>

SCC follows rigorous quality standards across their PCB fabrication and assembly process:

PCB Design

The process starts with customers submitting their PCB design files including schematics, layouts, and gerber data. SCC reviews the designs and works closely with customers to ensure manufacturability. Their engineering team optimizes the designs to avoid any fabrication issues.

Raw Material Procurement

SCC sources the base materials like laminates, prepregs, foils, etc. from reputed global partners like Rogers, Arlon, Isola, etc. They maintain strict raw material inspection, storage, and traceability procedures.

Inner Layer Manufacturing

For multi-layer boards, the individual inner layers are fabricated first. This involves several steps like:

- Drilling – Holes are drilled as per circuit design using CNC drilling machines.

- Etching – Unwanted copper is chemically etched away leaving only the desired circuit pattern.

- Inner Layer Lamination – Individual layers are bonded using high-pressure + high-temperature lamination process.

Outer Layer Manufacturing

The outer layers are fabricated using similar drilling, etching, and lamination processes. Additional steps include:

- Imaging – Photoresist coating and lithographic processes transfer the circuit patterns onto layers.

- Plating – Electrolytic copper plating builds up traces to desired thickness.

- Stripping – Photoresist is chemically removed.

- Etching – Exposed copper is etched away.

- Outer Layer Lamination – Multi-layer stack up is bonded together.

Post-Lamination Processes

- Via Drilling/Plating – Interlayer connections are made by drilling/plating through-hole vias.

- Soldermask Coating – Epoxy soldermask is applied providing insulation and branding.

- Silkscreen Printing – Component legends and identifiers are printed.

- Surface Finish – Final metal finish like ENIG, immersion tin, OSP, etc. is applied.

- Electrical Testing – Continuity, resistance, and voltage breakdown tests are conducted.

- Visual Inspection – Stringent optical inspection validates quality.

- Panel Routing – Individual PCBs are routed from larger panels.

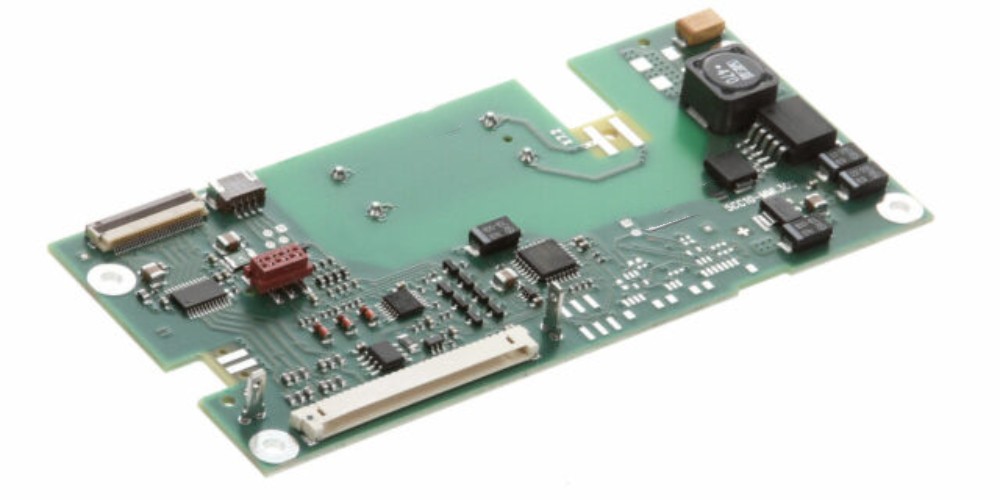

PCB Assembly

SCC also provides full turnkey PCB assembly including:

- SMT Assembly – Surface mount components are precisely placed and soldered.

- Manual Assembly – Odd-form components are hand-soldered.

- Conformal Coating – Protective coatings are applied.

- Programming – Necessary firmware/software is loaded.

- Testing – Comprehensive testing validates assembly quality.

<h3>SCC PCB Production Capabilities</h3>

| PCB Type | Capabilities |

|---|---|

| Layers | Up to [number] layers |

| Minimum Trace Width | [dimension] |

| Minimum Hole Size | [dimension] |

| Panel Size | Max [dimensions] |

| Materials | FR-4, Rogers, Isola, Arlon, etc. |

| Layer Stack Up | Any sequence of rigid, flex, rigid-flex layers |

| Finishes | HASL, Imm. Tin, Imm. Silver, ENIG, OSP, etc. |

| Testing | Flying probe, boundary scan, ICT, functional testing |

| Certifications | ISO 9001, IATF 16949, AS 9100, ITAR, IPC Class 2 & 3, UL, ROHS |

<h2>Benefits of Using SCC PCB Manufacturer</h2>

- One-stop-shop – Get PCB fabrication, assembly, and testing all from a single source. Reduces complexity.

- Flexibility – SCC works with customers to manufacture a wide range of PCB technologies and configurations.

- Quality – Stringent process controls and inspection ensures zero-defect, reliable PCBs.

- Fast turnaround – Quick-turn prototypes in as little as 24 hours.

- Cost-effective – Competitive pricing due to efficient manufacturing and economies of scale.

- Customer support – Dedicated engineers provide design, documentation, and technical assistance.

<h2>SCC PCB Applications</h2>

SCC manufactures PCBs for a diverse range of applications:

Automotive

- Engine control units

- Infotainment systems

- ADAS modules

- Lighting systems

- EV battery controllers

Aerospace and Defense

- Avionics systems

- Radar and communication

- Missile guidance systems

Medical

- Patient monitoring systems

- Diagnostic imaging equipment

- Dialysis machines

- Surgical robots

Industrial

- Motor drives

- PLCs

- Process instrumentation

- Power supplies

Telecom Infrastructure

- 5G small cells

- Optical networking

- Cell tower electronics

- Routers and switches

Consumer Electronics

- Smartphones and tablets

- Laptops and PCs

- Smart home devices

- IoT products

<h2>Frequently Asked Questions</h2>

What are the different types of PCBs SCC manufactures?

SCC manufactures all varieties of PCBs including single-sided, double-sided, multi-layer, HDI, rigid-flex, and metal-based PCBs. They can manufacture PCBs with up to [number] conductive layers.

What design file formats does SCC accept?

SCC accepts Gerber, ODB++, IPC-2581, and other standard PCB file formats. It is recommended to contact SCC early in the design cycle to ensure optimal manufacturability.

What are SCC’s quality certifications?

SCC maintains ISO 9001, IATF 16949, AS 9100 certifications. They are also ITAR registered and meeting IPC Class 2 and Class 3 standards for fabrication and assembly.

How long is the typical lead time?

Lead times depend on several factors but typical production lead times range from 2-4 weeks. For prototypes, SCC provides 24-48 hour quick-turn services.

Does SCC provide assembly services?

Yes, SCC provides full turnkey PCB assembly. This includes SMT, through-hole, conformal coating, programming, functional testing, etc.

Leave a Reply