Introduction

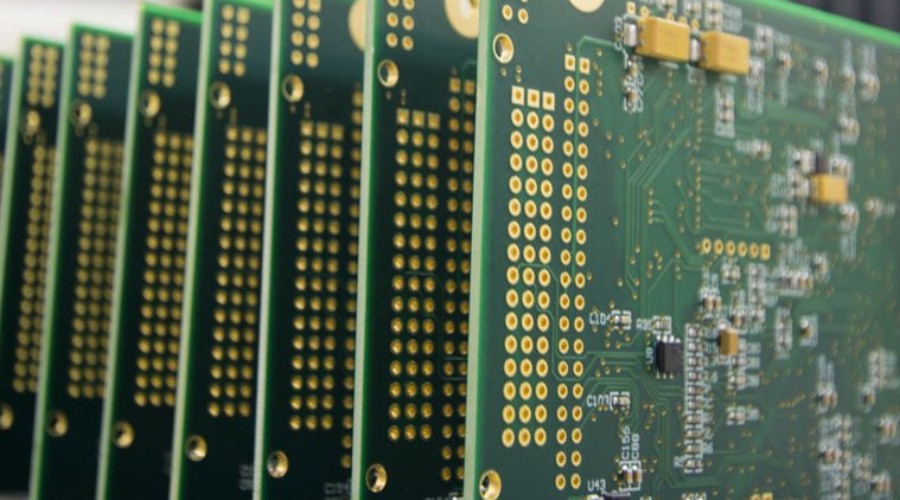

Printed circuit boards (PCBs) are at the heart of most modern electronics. They provide the foundation on which components are mounted and interconnected. For engineers and product developers, having access to quick turn PCB prototypes enables faster iteration and innovation.

As products become more advanced, PCBs have grown more complex. Developing a new PCB design from scratch is a challenging process requiring schematic capture, board layout, design rule checking and more. This process can take weeks or months using traditional workflows. When an error is found, additional rounds of revisions add further delays. The long lead times of traditional PCB fabrication further slow time-to-market.

Quick turn PCB services provide a solution to accelerate electronics development. By tapping into specialized supply chains and streamlined processes, these services can deliver custom PCB prototypes in as little as 24 hours. For engineers and companies racing to develop new products, quick turn services facilitate faster iteration and market introduction.

Benefits of Quick Turn PCBs

Quick turn PCB services offer a number of compelling benefits:

Faster Iteration Cycles

With standard PCB fabrication lead times of 2-4 weeks, waiting for prototypes inhibits development velocity. Quick turn services shrink this timeline down to 1 day by prioritizing rush orders. Getting PCBs in 24 hours instead of weeks results in dramatically shorter iteration cycles. Multiple design spins can be tested in the time it usually takes to produce one prototype.

Accelerated Testing

Having prototypes in hand sooner allows developers to start testing earlier. Verifying that a design works properly is critical. The sooner testing can begin, the faster any issues can be found and fixed. Quick turn PCBs enable testing to run in parallel with the development process instead of sequentially after.

Rapid Design Finalization

With ability to iterate faster, developers can quickly finalize and verify their design. Shorter revision loops let the design be refined until all specifications are dialed in. This reduces the likelihood of surprises and costly mistakes happening down the line during manufacturing ramp up.

Faster Time-to-Market

Getting working prototypes sooner accelerates the whole development schedule. Cutting weeks or months off the cycle time results in products shipping earlier. First to market products tend to achieve greater adoption and higher margins. Quick turn PCBs help enable faster time-to-market.

When to Use Quick Turn PCB Prototypes

While quick turn services offer huge time savings, their specialty processes come at a premium cost. When should developers pay extra for rapid prototyping versus use standard fabrication?

Design Finalization

During the design refinement and verification stage, quick turn PCBs make lots of sense. Many small iterations are needed to test and finalize the design prior to release. The premium cost of quick turn prototypes is well worth the prevented costs of mistakes caught earlier.

Market Windows

If a product needs to launch by a certain date to meet a market window, quick turn PCBs help ward off schedule slips. Their extra cost is justified to enable market introduction timing. Shipping late may mean permanently forfeiting opportunities.

Funding Milestones

For startups and inventors, hitting funding milestones on time is critical. Quick turn prototypes demonstrates progress to investors to unlock additional funding rounds. Their premium cost is an investment in securing capital.

Market Testing

Before committing to volume production, having prototypes on hand allows market testing. Quick turn PCBs help enable test marketing, demos, and pilots to validate demand. Preventing potential flops avoids sunk costs.

How Quick Turn PCB Fabrication Works

Delivering custom PCBs in 24 hours or less requires optimized processes. Here is an overview of how quick turn fabrication can produce prototypes so rapidly:

Specialized Supply Chain

Quick turn facilities maintain local sourcing of raw PCB materials. Keeping a ready stock of bare boards and chemicals on-hand avoids lead times of ordering from external suppliers.

Prioritization

Quick turn fabrication prioritizes rush orders ahead of standard jobs. A separate quick turn line focuses just on handling expedited orders to meet tighter deadlines.

Continuous Operation

Some facilities run 24/7 operations to start processing rush orders as soon as they arrive. Avoiding shutdowns on nights and weekends helps reduce lead times.

Automatedworkflows

Production tasks are highly automated using the latest processes. This eliminates bottlenecks while minimizing opportunities for human errors to cause delays.

Parallelization

Multiple operations are performed in parallel instead of sequentially. This allows some steps to commence earlier and stages to be completed simultaneously.

Eliminated Backlogs

Quick turn lines only accept orders they can deliver in 24 hours or less. This avoids potential backlogs which could lead to delays. New orders are strictly limited to maintain capacity.

The combination of these and other optimizations enable the rapid turnaround of quick turn PCB services. While no shortcuts are taken on quality, specialized processes facilitate much faster prototyping.

Factors That Influence Quick Turn PCB Lead Times

Several factors impact the lead times achievable with quick turn PCB fabrication:

| Factor | Effect |

|---|---|

| Board layers | Additional layers increases fabrication time |

| Board size | Larger boards take longer to produce |

| Materials | Standard FR4 is fastest vs. exotic materials |

| Batch size | Single prototypes faster than multiple |

| Location | Proximity to fab facility reduces shipping time |

| Order complexity | More complex orders require more production time |

| Facility workload | Lead time varies based on facility utilization |

Developers should account for these factors when estimating delivery timelines. The fastest lead times are achieved with single sided or two layer boards using standard FR4 material. Complex designs or large batches will require more time.

Cost Tradeoffs of Quick Turn PCBs

The accelerated lead times of quick turn PCB prototypes come at a premium price. What are the cost tradeoffs developers should consider?

Non-Recurring Engineering Fees

Often quick turn services charge an upfront NRE fee to prepare a new design for production. This covers their engineering effort and design rule checks.

Rush Service Fees

A rush service fee is added to expedited orders to account for prioritized handling and overtime. This guarantees fast turnaround but increases cost.

Economy of Scale

Because quick turn services focus on small batches and rapid fabrication, they lack the economy of scale of higher volume production. The cost per unit is higher.

Convenience Premium

The ability to get fully custom prototypes delivered in 24 hours provides huge time savings. Developers pay a premium for this convenience.

Iteration Efficiency

Despite their higher per unit cost, quick turn PCBs can provide overall savings by preventing mistakes. The cost of fixing an issue late stage often exceeds the prototypes’ premium.

By accounting for these tradeoffs, developers can assess if quick turn PCBs make sense for a particular project. Their upfront premium cost may deliver substantial savings in accelerated development and reduced risk.

Quick Turn PCB Design Best Practices

Following some best practices during design will ensure the best results with quick turn fabrication:

- Use standard materials – FR4 is well suited for fast fabrication. Avoid exotic substrates.

- Prioritize two layer designs – Stick to one or two layers when possible. Additional layers mean more production steps.

- Design with manufacturability in mind – Avoid via stitching, complex traces, and other features that complicate fabrication.

- Use minimum features sizes – Thin traces and spaces will take more iterations to get right. Design with tolerance for errors.

- Adjust expectations on lead time – Understand the factors impacting fabrication time based on the complexity of your board.

- Check DRC before ordering – Fix any design rule errors yourself first instead of relying on the fabricator.

By designing with quick turn manufacturing in mind, developers can maximize their likelihood of success on the first prototype iteration.

Frequently Asked Questions

What are some examples of quick turn PCB applications?

Some examples include:

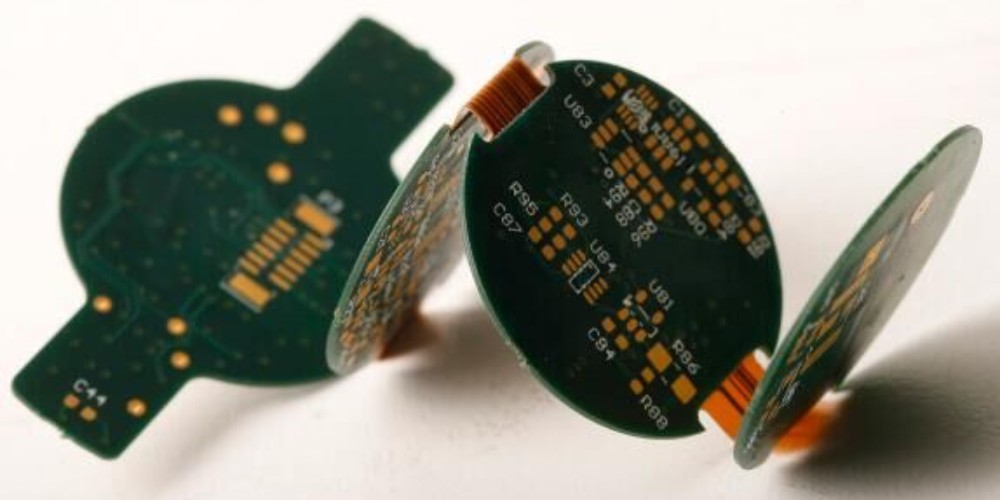

- Prototyping IoT products

- Testing new wearable electronics designs

- Validating interfaces for a new smartphone under development

- Finalizing a new drone autopilot board prior to production

- Developing boards for a new AI accelerator chip

What tolerances should I expect with quick turn PCBs?

With expedited fabrication timelines, some tolerances may be more relaxed. Expect tolerances of:

- Line width/space: +/- 6 mil

- Hole size: +/- 2 mil

- Hole to hole spacing: +/- 2 mil

For tighter tolerances, allow more time or involve the fabricator’s engineers.

Can I order SMT assembly with quick turn PCBs?

Some quick turn PCB facilities offer expedited assembly for prototypes. This allows fully assembled boards for testing in as little as 48 hours. Expect higher per unit costs with quick turn assembly due to smaller batch sizes.

How many quick turn iterations can I expect in a 1 week period?

Expect to receive at least 3 iterations of new prototypes when factoring in 24 hour fabrication time and 2 day shipping. If next day shipping is used, 4-5 iterations in a week may be possible.

Is there a minimum order quantity for quick turn PCBs?

Most quick turn facilities have no minimum order quantity. Even a single prototype board can be ordered. However, NRE costs are sometimes fixed regardless of order quantity. Ordering a few extra boards to validate the design may have minimal impact on cost.

Conclusion

For today’s fast paced electronics innovation, standard PCB fabrication timelines are no longer competitive. By tapping quick turn PCB services, companies can accelerate innovation and achieve quicker time to market. These specialized rapid fabrication techniques enable custom prototypes in just 24 hours.

Despite their premium pricing, quick turn PCB prototypes generate substantial savings by facilitating faster iteration, accelerated testing, and reduced risk. Their convenience premium provides strategic benefits of outpacing competition. By understanding the tradeoffs and following some design best practices, developers can effectively leverage quick turn services for optimized results in electronics creation.

Leave a Reply