h2. Introduction to Printed Circuit Boards A printed circuit board (PCB) is the foundation of almost every modern electronic device. It provides the mechanical structure and electrical connections between components in an electronic system. PCBs are made from insulating materials like fiberglass or plastic, with copper traces etched from copper foil to form the wiring between components. Components like integrated circuits, resistors, capacitors and more are soldered to the PCB to complete an electronic circuit.

PCBs enable the miniaturization and automation of electronic devices by condensing complex wiring into a compact format. They are ubiquitous across consumer electronics, industrial equipment, vehicles, aerospace systems, and more. The global PCB market was valued at over $72 billion USD in 2021 and is projected to grow steadily in the coming years.

As PCBs grow more complex to enable advanced capabilities, specialized PCB manufacturers are critical in transforming circuit designs into high-quality boards. This guide provides a comprehensive overview of PCB manufacturing, key considerations in selecting a PCB manufacturer, and profiles of leading global PCB manufacturers.

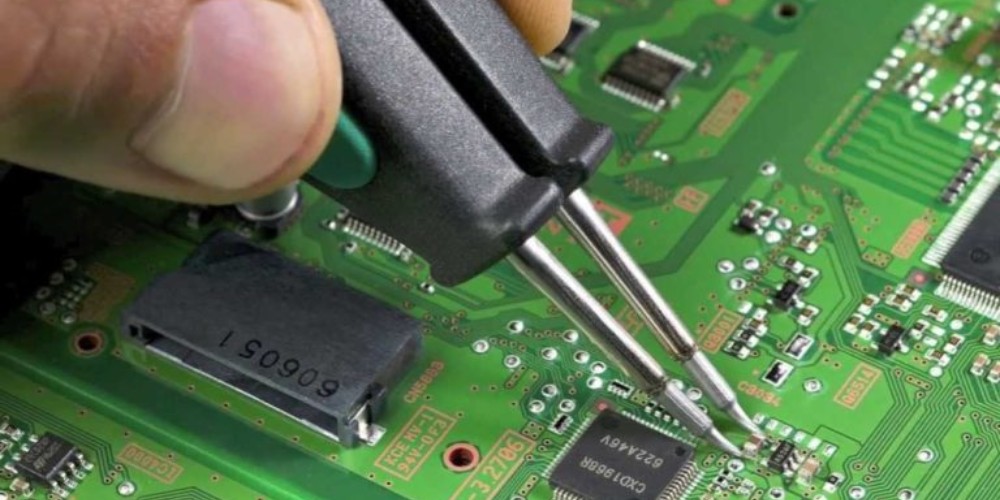

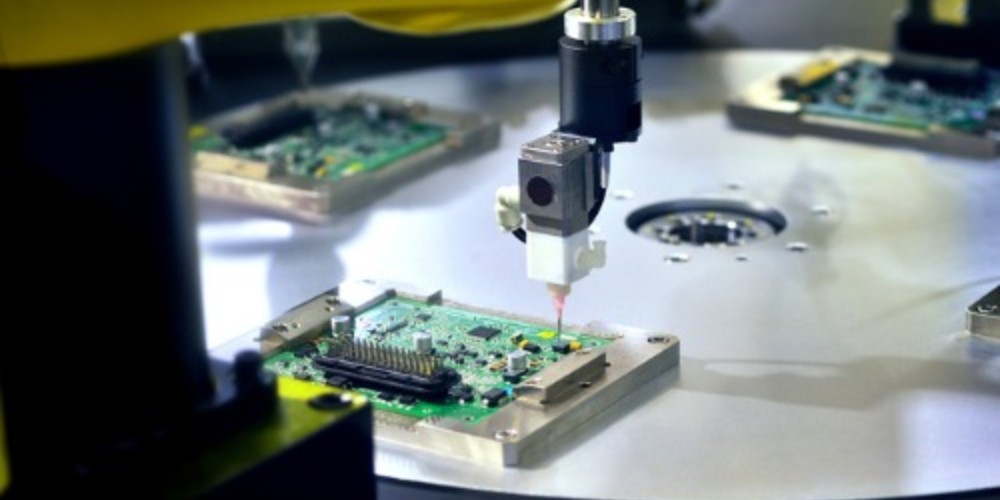

h2. Overview of the PCB Manufacturing Process There are seven major steps in manufacturing a PCB:<li>Design – The PCB layout is designed based on circuit requirements using CAD software. This generates Gerber files containing PCB artwork data.</li> <li>Prototyping – For new designs, a prototype PCB may be produced to verify the design before large scale manufacturing.</li> <li>Pre-production – Gerber files are reviewed to ensure manufacturability. Panel sizes, layer stackups and other specifications are finalized.</li> <li>Fabrication – Raw PCB materials are processed using lithography to selectively add and remove copper to form traces based on the PCB artwork.</li> <li>Assembly – Surface mount and through-hole components are soldered to the PCB either manually or via automation.</li> <li>Testing – Quality testing validates proper fabrication, electrical connectivity, and functional performance.</li> <li>Delivery -Finished PCBs are depanelized from larger boards into individual PCBs, then shipped to the customer.</li>

h2. Choosing a PCB Manufacturer With thousands of PCB manufacturers worldwide, it can be challenging to select the right partner for your project. Here are key factors to evaluate:

h3. Capabilities

- Does the manufacturer support your board’s size, layer count, density, and other specifications?

- Do they have qualified processes to handle high-frequency, high-speed, flexible, HDI, or other advanced PCBs?

- What is their experience with your industry and application?

h3. Quality

- Do they have robust quality management systems and certification such as ISO 9001 or IPC membership?

- What is their defect rate and on-time delivery rate? Do they offer warranties?

- Do they perform rigorous inspecting, testing, and documenting of quality?

h3. Services

- Do they offer engineering support, prototyping, assembly, and other value-added services?

- Do they have design for manufacturability (DFM) analysis to catch issues early?

- Can they manage your bill of materials (BOM) and supply chain logistics?

h3. Cost

- Do volume discounts match your projected order volumes?

- What are their upfront and hidden costs like tooling charges or expedited delivery fees?

- Do they offer affordable prototype rates to test designs before committing to production?

h3. Delivery & lead times

- How quickly can they deliver on production orders? Do they have rush/expedite options?

- Where are they located? Can they ship efficiently to your facilities?

h3. Customer service

- Is communication timely, helpful, and transparent?

- Do they assign customer service representatives for consistent support?

- How do they handle problems if they occur?

Weighing these factors thoroughly will help identify the ideal partner that aligns with your PCB requirements, budget, and timelines. Touring the manufacturer’s facilities can also provide valuable insights before selecting.

h2. Leading PCB Manufacturers Here are overviews of five globally leading PCB manufacturers across the Americas, Europe, and Asia.

h3. Advanced Circuits (USA) Based in Colorado, Advanced Circuits is a pioneer in PCB prototyping and production, with over 25 years of experience. They offer a 24 hour turnaround on prototyping orders of up to 100 boards. Their proprietary ‘FreeDFM’ tool instantly checks designs for manufacturability issues. Production capabilities include:

- 2 to 42 layers

- Trace/Space: 3/3mil

- Maximum size: 65in x 65in

- FR-4, polyimide, and other material options

- Lead-free fabrication and RoHS compliance

- ISO 9001:2015 and ISO 13485 certified

- ITAR registered

- Design support, assembly, and logistics services

Advanced Circuits serves diverse customers globally, from hobbyists to Fortune 500 companies across industries like aerospace, automotive, and medical devices.

h3. Eurocircuits (Europe) Headquartered in Austria, Eurocircuits offers quick-turn prototyping and scalable production of PCBs across Europe. They have an interactive online DFM tool for optimizing designs, with specialized support for flex, HDI and aluminum-based boards. Manufacturing capabilities include:

- Prototyping in as fast as 24 hours

- Up to 42 layers

- Minimum trace/space: 6/6mil

- Maximum size: 650 x 650mm

- FR4, CEM, ceramic, Teflon, Rogers materials

- EN, UL, ISO, and IATF 16949 quality certifications

- Design, assembly, and supply chain services

Eurocircuits’ quality management system ensures reliable on-time delivery of over 15,000 PCB designs annually. Their customers range from leading universities to aerospace companies across Europe.

h3. PCBCart (China) Founded in China in 2009, PCBCart has become one of the largest PCB manufacturers supplying customers globally through their Instant Quote & Order system. They have an agile manufacturing base in China to produce affordable, high-quality PCBs with:

- 24 hour prototyping turnaround time

- 2 to 32 layers

- Minimum trace/space: 4/4mil

- Maximum size: 546 x 610mm

- FR4, Rogers, ceramic, CEM, flex and aluminum materials

- Aerospace, automotive, medical, and telecom certifications

- Value-added services like assembly, testing, machining

PCBCart provides cost-effective prototyping and production orders from 10 boards to over 10,000 boards. Their US-based support team provides responsive assistance with orders and design issues.

h3. Sierra Circuits (USA) Headquartered in California with manufacturing in the US and overseas, Sierra Circuits excels at quick-turn PCB prototyping and ramping designs into production. Their online quoting system can provide fabrication quotes within minutes. Capabilities include:

- Prototyping in 24 hours

- Up to 30 layers

- Minimum trace/space: 3/3mil

- Maximum size: 65in x 65in

- FR4, polyimide, Rogers, flex, and metal core PCBs

- ITAR registered

- Design reviews, assembly, testing, and fulfillment

Sierra Circuits provides innovative PCB solutions to customers of all sizes, from new product developers to Fortune 100 companies across diverse industries. Their quality management system ensures efficient problem resolution and continuous improvement.

h3. Würth Elektronik CBT (Germany) Würth Elektronik CBT is a division of Würth Elektronik specialized in printed circuit boards, with facilities across Germany, Europe and China. They offer full turnkey services from design to delivery for rigid, flex, and HDI PCBs. Key capabilities include:

- 2 to 30 layers

- Minimum trace/space: 25/25um

- Maximum size: 480 x 600mm

- Ultra-HDI technology down to 15/15um lines/spaces

- eMobility, communication, industrial, and medical applications

- Rigorous process and quality control

- UL, ISO, AQAP certifications

- Global logistics network

Würth Elektronik CBT serves over 125,000 customers worldwide. Their expertise in HDI, microwave, and flex PCBs makes them a strategic partner for developing cutting-edge electronic devices.

h2. Comparing PCB Manufacturers To summarize key differentiators, here is a comparison of capabilities across the profiled PCB manufacturers:

| Manufacturer | Location | Max Layers | Minimum Spacing | Lead Time | Key Specialties |

|---|---|---|---|---|---|

| Advanced Circuits | USA | 42 | 3/3mil | 24 hour prototyping | Prototyping, aerospace/defense |

| Eurocircuits | Europe | 42 | 6/6mil | 24 hour prototyping | HDI, flex PCBs |

| PCBCart | China | 32 | 4/4mil | 24 hour prototyping | Affordable production |

| Sierra Circuits | USA | 30 | 3/3mil | 24 hour prototyping | Quick-turn prototyping |

| Würth Elektronik CBT | Germany | 30 | 15/15um | N/A | HDI, flex, RF PCBs |

This comparison shows the diversity of strengths across these leading manufacturers. Identifying the capabilities that best match your specific requirements will help determine which is the optimal partner for your needs.

h2. FQA on Printed Circuit Board Manufacturing Here are answers to some frequently asked questions about printed circuit board manufacturing:

h3. What are the different types of PCBs? The most common PCB types are:

- Rigid – Made of rigid FR4 fiberglass material. The most widely used PCB type.

- Flexible – Made of flexible polymer materials that can bend and flex. Used where movement is required.

- Rigid-flex – Combines rigid PCB sections with flexible interconnects between sections. Provides flexibility where needed.

- HDI (High Density Interconnect) – Have trace spacing and vias under 100um for increased component density. Used in miniaturized products.

- Multilayer – Have 3 or more copper layers laminated together, allowing greater complexity. Used in high performance systems.

h3. How long does PCB manufacturing take? A typical timeline for PCB manufacturing is:

- Prototyping: Can be as fast as 24-48 hours for simple boards, but 5-7 days is more common.

- Production: Generally 3 to 4 weeks from order placement to delivery for conventional PCBs. Lead times can extend to 8+ weeks for advanced PCBs.

- Expedited builds: “Rush” and “super rush” options can shorten lead times to 5-7 days if capacities allow.

h3. What files do I need to provide for PCB manufacturing? You need to provide Gerber files which contain all the PCB layout information extracted from your CAD software. Other files like assembly drawings, drill files, BOMs, and pick-and-place data may also be needed depending on your full requirements.

h3. Can manufacturers help optimize my design?

Yes, good manufacturers offer design reviews and DFM analysis before production. This helps catch problems early so the design can be tweaked to improve manufacturability, avoid issues during production, and lower costs.

h3. How much does PCB manufacturing cost? Cost depends on size, layer count, complexity, lead time, and order volume. Simple prototype boards can cost $50 and up, while complex production boards can cost up to $10,000. Work with your manufacturer to optimize cost.

h2. Conclusion As the core of modern electronics, quality PCB manufacturing is critical yet often overlooked. Carefully choosing a manufacturer that aligns with your technical requirements, quality expectations, and business needs is key to ensuring your products have a solid foundation. Do thorough diligence on manufacturers under consideration using the guidelines provided. Finally, leverage the expertise of the manufacturer to strengthen your design and avoid pitfalls. The partnership with your PCB manufacturer can determine the success or failure of getting innovative products to market quickly.

Leave a Reply