What is PCB Troubleshooting?

PCB troubleshooting is the process of identifying, diagnosing, and resolving issues with printed circuit boards. It involves a systematic approach to pinpoint the root cause of a problem and implement an appropriate solution. The purpose of PCB troubleshooting is to ensure that the electronic circuit functions as intended, minimizing downtime and maximizing performance.

Why is PCB Troubleshooting Important?

PCB troubleshooting is crucial for several reasons:

-

Identifying Faults: Troubleshooting helps identify faults in the PCB, such as short circuits, open circuits, or component failures.

-

Preventing Damage: By detecting and resolving issues early, troubleshooting prevents further damage to the PCB and other components.

-

Saving Time and Money: Effective troubleshooting minimizes downtime and reduces the need for costly replacements or repairs.

-

Improving Reliability: Regularly troubleshooting and maintaining PCBs enhances their reliability and longevity.

Common PCB Problems and Their Causes

Several common problems can arise in PCBs. Understanding these issues and their causes is essential for effective troubleshooting.

Short Circuits

Short circuits occur when two or more points in a circuit that should not be connected are inadvertently joined. This can happen due to:

- Solder bridges: Excess solder connecting adjacent pads or traces

- Conductive debris: Loose metal particles or filings causing unintended connections

- Damaged insulation: Worn or damaged insulation allowing wires to touch

Open Circuits

Open circuits happen when there is a break in the conductive path, preventing current from flowing. Causes include:

- Broken traces: Physical damage to the PCB traces

- Cracked solder joints: Solder joints that have cracked due to stress or thermal cycling

- Faulty components: Components that have failed or become disconnected

Component Failures

Components on a PCB can fail due to various reasons:

- Overheating: Excessive heat causing components to degrade or fail

- Overcurrent: Current exceeding the component’s rated capacity

- Electrostatic discharge (ESD): Sudden flow of electricity damaging sensitive components

- Aging: Components reaching the end of their lifespan

Design Flaws

Sometimes, PCB problems arise due to design flaws:

- Incorrect component selection: Using components that are not suitable for the application

- Improper routing: Suboptimal placement of traces and components leading to signal integrity issues

- Insufficient protection: Lack of proper protection circuits, such as fuses or transient voltage suppressors

PCB Troubleshooting Techniques

To effectively troubleshoot PCBs, a combination of visual inspection, testing, and analysis techniques is required.

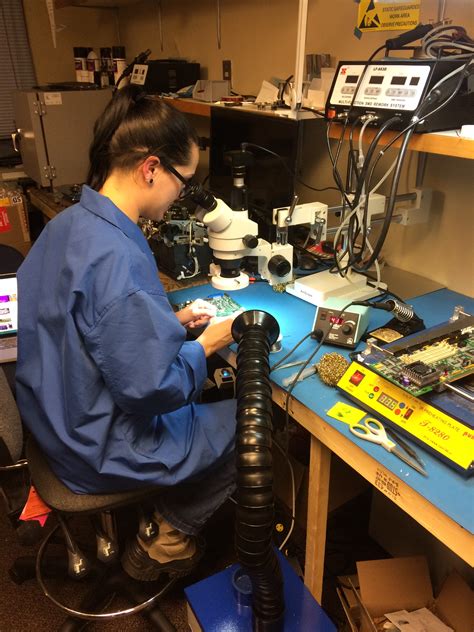

Visual Inspection

Visual inspection is the first step in PCB troubleshooting. It involves carefully examining the board for any visible defects or anomalies. Look for:

- Solder bridges or Cold Solder joints

- Broken or damaged components

- Burnt or discolored areas

- Foreign objects or debris

Continuity Testing

Continuity testing checks for open circuits by verifying that there is a continuous electrical path between two points. Use a multimeter to:

- Test for continuity between pins or pads that should be connected

- Check for shorts between traces or components that should be isolated

Voltage and Current Measurements

Measuring voltages and currents at various points in the circuit helps identify issues related to power supply, signal integrity, and component health. Use a multimeter or oscilloscope to:

- Verify power supply voltages

- Measure voltage drops across components

- Monitor current consumption of individual components or the entire board

Thermal Imaging

Thermal imaging cameras detect heat patterns on the PCB, helping identify components that are overheating or areas with poor thermal dissipation. This technique is particularly useful for:

- Locating components that are running hotter than expected

- Identifying areas with insufficient cooling or thermal management

Signal Analysis

Signal analysis involves examining the electrical signals on the PCB to ensure they meet the expected specifications. Use an oscilloscope to:

- Verify signal integrity, such as rise/fall times, overshoot, and undershoot

- Check for noise, crosstalk, or other signal disturbances

- Analyze timing and synchronization between signals

Troubleshooting Steps

When approaching PCB troubleshooting, follow these steps to systematically identify and resolve issues:

-

Gather Information: Collect all relevant information about the PCB, including schematics, layout files, and component datasheets.

-

Perform Visual Inspection: Carefully examine the PCB for any visible defects or anomalies.

-

Check Power Supply: Verify that the power supply voltages are within the specified range and stable.

-

Test Continuity: Use a multimeter to check for open circuits and short circuits.

-

Measure Voltages and Currents: Measure voltages and currents at key points in the circuit to identify any deviations from expected values.

-

Analyze Signals: Use an oscilloscope to examine electrical signals and ensure they meet the required specifications.

-

Isolate the Problem: Narrow down the issue to a specific component, section, or subsystem of the PCB.

-

Replace or Repair: Once the faulty component or area is identified, replace or repair it as necessary.

-

Retest and Verify: After making the necessary repairs, retest the PCB to ensure it functions correctly and meets all requirements.

Preventive Measures

To minimize the occurrence of PCB problems, consider implementing the following preventive measures:

- Proper Handling: Handle PCBs with care, using ESD-safe techniques and equipment.

- Regular Cleaning: Periodically clean the PCB to remove dust, debris, and contaminants that can cause issues.

- Thermal Management: Ensure adequate cooling and thermal management to prevent overheating of components.

- Protective Circuits: Include appropriate protective circuits, such as fuses and transient voltage suppressors, to safeguard against electrical faults.

- Quality Control: Implement strict quality control measures during PCB Fabrication and assembly to catch defects early.

Troubleshooting Tools and Equipment

To effectively troubleshoot PCBs, you will need the following tools and equipment:

| Tool | Purpose |

|---|---|

| Multimeter | Measure voltage, current, resistance, and continuity |

| Oscilloscope | Analyze electrical signals and waveforms |

| Soldering Iron | Repair or replace components on the PCB |

| Desoldering Pump | Remove solder from joints for component removal |

| Tweezers | Handle small components and wires |

| Magnifying Glass | Inspect PCB for visual defects and anomalies |

| ESD-safe Workstation | Protect sensitive components from electrostatic discharge |

| Thermal Camera | Identify components and areas with excessive heat |

FAQ

-

What are the most common causes of PCB Failures?

The most common causes of PCB failures include short circuits, open circuits, component failures, and design flaws. These issues can arise due to various factors, such as solder bridges, damaged insulation, overheating, overcurrent, electrostatic discharge, and aging. -

How can I prevent short circuits on my PCB?

To prevent short circuits, ensure proper soldering techniques to avoid solder bridges. Keep the PCB clean and free from conductive debris. Inspect the board regularly for any signs of damage or wear to the insulation. -

What should I do if I suspect a component failure on my PCB?

If you suspect a component failure, start by visually inspecting the component for any signs of damage or discoloration. Use a multimeter to check the component’s continuity and measure its voltage and current. If the component is faulty, replace it with a new one of the same specifications. -

How can I identify design flaws in my PCB?

Identifying design flaws requires a thorough review of the PCB schematics and layout. Look for issues such as incorrect component selection, improper routing, or insufficient protection circuits. Consult with experienced PCB designers or use simulation tools to validate the design before fabrication. -

What are some best practices for handling and storing PCBs to minimize the risk of damage?

Always handle PCBs with care, using ESD-safe techniques and equipment. Store PCBs in a cool, dry place away from direct sunlight and moisture. Use anti-static bags or containers to protect the boards from electrostatic discharge. Avoid exposing PCBs to extreme temperatures or mechanical stress.

Conclusion

PCB troubleshooting is a critical skill for anyone working with electronic circuits. By understanding the common problems, their causes, and effective troubleshooting techniques, you can quickly identify and resolve issues with your PCBs. Remember to approach troubleshooting systematically, using a combination of visual inspection, testing, and analysis methods.

Investing in the right tools and equipment, such as multimeters, oscilloscopes, and ESD-safe workstations, will make your troubleshooting process more efficient and accurate. Additionally, implementing preventive measures, such as proper handling, regular cleaning, and quality control, can help minimize the occurrence of PCB problems.

By following the guidelines and best practices outlined in this ultimate guide, you’ll be well-equipped to tackle any PCB troubleshooting challenges that come your way, ensuring the reliability and performance of your electronic circuits.

Leave a Reply