What is a PCB Solder Mask?

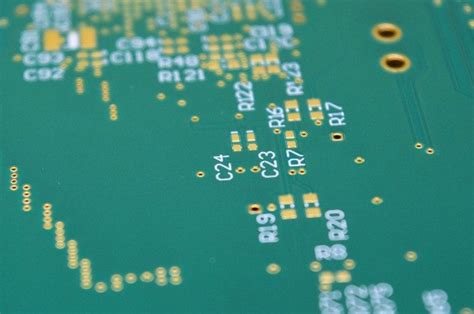

A PCB (Printed Circuit Board) solder mask is a thin layer of polymer that is applied to the copper traces of a PCB during the manufacturing process. The main purpose of the solder mask is to protect the copper traces from oxidation, prevent solder bridges from forming between closely spaced pads, and provide electrical insulation. The solder mask also helps to improve the aesthetics of the PCB by providing a uniform color and texture to the board surface.

Types of Solder Mask

There are two main types of solder mask used in PCB manufacturing:

-

Liquid Photo Imageable (LPI) Solder Mask: This type of solder mask is applied as a liquid and then exposed to UV light through a photographic film. The exposed areas of the solder mask harden and become resistant to the developer solution, while the unexposed areas are washed away. LPI solder mask is the most common type used in PCB manufacturing due to its high resolution and ability to conform to the surface of the PCB.

-

Dry Film Solder Mask: This type of solder mask is applied as a thin, dry film that is laminated onto the surface of the PCB. The film is then exposed to UV light through a photographic film, and the exposed areas of the film harden and become resistant to the developer solution. Dry film solder mask is less common than LPI solder mask but is still used in some applications.

Common PCB Solder Mask Colors

While the primary function of the solder mask is to protect the copper traces and provide insulation, the color of the solder mask can also serve important purposes. Different colors can be used to indicate different functions or characteristics of the PCB, such as power planes, ground planes, or high-voltage areas. The most common PCB solder mask colors are:

1. Green

Green is the most common color for PCB solder masks and is often used as a default color when no specific color is required. Green solder mask provides good contrast with the white silkscreen and makes it easy to inspect the PCB for defects.

2. Red

Red solder mask is often used to indicate power planes or high-voltage areas on the PCB. The bright color makes it easy to identify these areas and helps to prevent accidental contact with dangerous voltages.

3. Blue

Blue solder mask is sometimes used as an alternative to green for aesthetic reasons. It provides good contrast with the white silkscreen and can make the PCB look more visually appealing.

4. Black

Black solder mask is often used for high-end or military-grade PCBs. It provides a sleek, professional look and can help to hide proprietary circuitry or components.

5. White

White solder mask is less common than other colors but can be used for specific applications. It can provide good contrast with black or dark-colored components and can make the PCB easier to inspect.

6. Yellow

Yellow solder mask is sometimes used to indicate high-voltage areas on the PCB, similar to red solder mask. It provides good visibility and helps to prevent accidental contact with dangerous voltages.

Advantages of Using Different Solder Mask Colors

Using different colors of solder mask on a PCB can provide several advantages, including:

-

Improved Aesthetics: Different colors of solder mask can make the PCB look more visually appealing and professional. This can be especially important for consumer products or high-end applications.

-

Increased Functionality: Different colors can be used to indicate different functions or characteristics of the PCB, such as power planes or ground planes. This can make it easier for technicians to identify and work with specific areas of the board.

-

Enhanced Inspection: Different colors of solder mask can provide better contrast with the silkscreen and components, making it easier to inspect the PCB for defects or errors.

-

Improved Safety: Bright colors like red or yellow can be used to indicate high-voltage areas on the PCB, helping to prevent accidental contact with dangerous voltages.

Factors to Consider When Choosing a Solder Mask Color

When choosing a solder mask color for a PCB, there are several factors to consider, including:

-

Application: The intended use of the PCB should be taken into account when choosing a solder mask color. For example, military-grade PCBs may require a specific color like black, while consumer products may benefit from a more visually appealing color like blue or white.

-

Functionality: If the PCB has specific functional requirements, such as high-voltage areas or power planes, a specific color like red or yellow may be necessary to indicate these areas.

-

Contrast: The solder mask color should provide good contrast with the silkscreen and components to make the PCB easier to inspect and work with.

-

Cost: Some colors of solder mask may be more expensive than others due to the materials or processes involved. The cost of the solder mask should be taken into account when choosing a color.

PCB Solder Mask Color Comparison Table

| Color | Common Uses | Advantages | Disadvantages |

|---|---|---|---|

| Green | Default color, general purpose | Good contrast with silkscreen, easy to inspect | May not be visually appealing for some applications |

| Red | Power planes, high-voltage areas | Easily identifiable, improves safety | May be more expensive than other colors |

| Blue | Aesthetics, general purpose | Visually appealing, good contrast with silkscreen | May not be suitable for some applications |

| Black | High-end or military-grade PCBs | Sleek and professional look, can hide proprietary circuitry | May be more expensive, can be difficult to inspect |

| White | Specific applications, contrast with dark components | Good contrast with black or dark components | May be more expensive, can be difficult to keep clean |

| Yellow | High-voltage areas | Good visibility, improves safety | May be more expensive than other colors |

FAQ

-

Q: What is the most common PCB solder mask color?

A: Green is the most common PCB solder mask color and is often used as a default color when no specific color is required. -

Q: Can I use any color of solder mask on my PCB?

A: While there are many colors of solder mask available, some colors may be more suitable for specific applications or requirements. It’s important to consider factors like functionality, contrast, and cost when choosing a solder mask color. -

Q: Is there a difference in performance between different colors of solder mask?

A: The color of the solder mask does not typically affect the performance of the PCB. However, some colors may be more suitable for certain applications, such as high-voltage areas or military-grade PCBs. -

Q: How does the solder mask color affect the manufacturing process?

A: The color of the solder mask does not typically affect the manufacturing process itself, but some colors may require specific materials or processes that can affect the cost or lead time of the PCB. -

Q: Can I change the color of the solder mask on an existing PCB?

A: Once the solder mask has been applied to the PCB, it is not possible to change the color without completely removing the existing solder mask and applying a new one. This process can be time-consuming and expensive, so it’s important to choose the right color from the start.

Conclusion

PCB solder mask colors serve important functions beyond just aesthetics. Different colors can be used to indicate specific areas or characteristics of the PCB, such as power planes or high-voltage areas. The most common PCB solder mask colors are green, red, blue, black, white, and yellow, each with its own advantages and disadvantages.

When choosing a solder mask color, it’s important to consider factors like the intended application, functionality, contrast, and cost. Using the right color of solder mask can improve the aesthetics, functionality, and safety of the PCB, while also making it easier to inspect and work with.

By understanding the different colors of PCB solder mask available and their specific uses and advantages, PCB designers and manufacturers can make informed decisions and create high-quality, reliable PCBs that meet the needs of their intended applications.

Leave a Reply