Introduction to PCB Assembly

Printed Circuit Board (PCB) assembly is the process of soldering electronic components onto a PCB to create a functional electronic device. PCB assembly service providers offer a range of services to help customers design, manufacture, and assemble PCBs for various applications. In this article, we will discuss the PCB assembly process, the types of PCB assembly services available, and the factors to consider when choosing a PCB assembly service provider.

What is PCB Assembly?

PCB assembly is the process of attaching electronic components to a printed circuit board to create a functional electronic device. The process involves several steps, including:

- Solder Paste Application

- Component Placement

- Reflow Soldering

- Inspection and Testing

Solder Paste Application

Solder paste is a mixture of tiny solder particles and flux that is applied to the PCB pads where the components will be placed. The solder paste is usually applied using a stencil or screen printing process.

Component Placement

Once the solder paste is applied, the electronic components are placed on the PCB using a pick-and-place machine. The machine uses a vacuum nozzle to pick up the components and place them on the PCB with high precision.

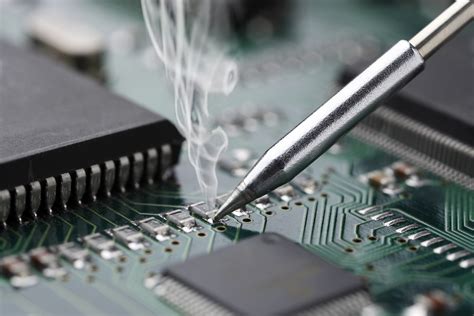

Reflow Soldering

After the components are placed, the PCB goes through a reflow soldering process. The PCB is heated in an oven until the solder paste melts and forms a permanent connection between the components and the PCB pads.

Inspection and Testing

Finally, the assembled PCB goes through a series of inspections and tests to ensure that it functions correctly and meets the required specifications. This may include visual inspections, automated optical inspections (AOI), and functional testing.

Types of PCB Assembly Services

PCB assembly service providers offer a range of services to meet the needs of different customers. Some of the most common types of PCB assembly services include:

Prototype PCB Assembly

Prototype PCB assembly is the process of assembling a small number of PCBs for testing and validation purposes. This service is often used by customers who are developing new products and need to test their designs before moving to full-scale production.

Low-Volume PCB Assembly

Low-volume PCB assembly is the process of assembling a small to medium number of PCBs, typically less than 1,000 units. This service is often used by customers who have a limited production run or who are testing the market for a new product.

High-Volume PCB Assembly

High-volume PCB assembly is the process of assembling a large number of PCBs, typically more than 1,000 units. This service is often used by customers who have a well-established product and need to produce large quantities to meet demand.

Turnkey PCB Assembly

Turnkey PCB Assembly is a comprehensive service that includes all aspects of PCB assembly, from design to final testing and packaging. This service is often used by customers who want a complete solution for their PCB assembly needs.

Factors to Consider When Choosing a PCB Assembly Service Provider

When choosing a PCB assembly service provider, there are several factors to consider to ensure that you get the best service and quality for your needs. Some of the most important factors include:

Experience and Expertise

Look for a PCB assembly service provider with a proven track record of success and expertise in the specific type of PCB assembly you require. Ask for references and examples of previous work to ensure that they have the necessary experience and skills.

Quality Control

Ensure that the PCB assembly service provider has a robust quality control process in place to ensure that your PCBs are assembled to the highest standards. Ask about their inspection and testing procedures and whether they have any quality certifications, such as ISO 9001.

Turnaround Time

Consider the turnaround time offered by the PCB assembly service provider. If you have a tight deadline, ensure that they can meet your needs and deliver your PCBs on time.

Cost

Compare the costs of different PCB assembly service providers to ensure that you are getting a competitive price for the services you require. However, be wary of providers that offer prices that seem too good to be true, as this may indicate lower quality or hidden costs.

Communication and Customer Service

Look for a PCB assembly service provider that has excellent communication and customer service. They should be responsive to your inquiries and keep you informed throughout the assembly process. Good customer service can make a big difference in the overall experience and ensure that any issues are resolved quickly and efficiently.

PCB Assembly Process

The PCB assembly process typically involves several steps, each of which is critical to ensuring the quality and functionality of the final product. Here is a more detailed breakdown of the PCB assembly process:

| Step | Description |

|---|---|

| Design | The PCB design is created using specialized software, such as Eagle or Altium Designer. The design includes the layout of the components, traces, and other features of the PCB. |

| Fabrication | The PCB is fabricated using a variety of methods, such as etching, drilling, and plating. The fabrication process creates the physical board that will be used for assembly. |

| Solder Paste Application | Solder paste is applied to the PCB pads using a stencil or screen printing process. The solder paste consists of tiny solder particles suspended in a flux material that helps the solder flow and adhere to the pads. |

| Component Placement | The electronic components are placed on the PCB using a pick-and-place machine. The machine uses a vacuum nozzle to pick up the components and place them on the PCB with high precision. |

| Reflow Soldering | The PCB is heated in a reflow oven until the solder paste melts and forms a permanent connection between the components and the PCB pads. The reflow process typically involves a specific temperature profile that is designed to ensure optimal solder joint formation. |

| Inspection and Testing | The assembled PCB is inspected and tested to ensure that it meets the required specifications and functions correctly. This may include visual inspections, automated optical inspections (AOI), X-ray inspections, and functional testing. |

Advantages of Using a PCB Assembly Service Provider

Using a PCB assembly service provider offers several advantages over assembling PCBs in-house. Some of the main advantages include:

Access to Specialized Equipment

PCB assembly service providers have access to specialized equipment, such as pick-and-place machines, reflow ovens, and inspection equipment, that may be too expensive or impractical for individual customers to purchase and maintain.

Expertise and Experience

PCB assembly service providers have a team of experienced professionals who specialize in PCB assembly. They have the knowledge and skills to ensure that your PCBs are assembled to the highest standards and meet your specific requirements.

Cost Savings

Outsourcing PCB assembly can be more cost-effective than assembling PCBs in-house, particularly for low-volume or prototype production runs. PCB assembly service providers can often offer lower prices due to their economies of scale and purchasing power.

Faster Turnaround Times

PCB assembly service providers can often offer faster turnaround times than in-house assembly, particularly for high-volume production runs. They have streamlined processes and dedicated resources that allow them to assemble PCBs quickly and efficiently.

Quality Assurance

PCB assembly service providers have robust quality control processes in place to ensure that your PCBs are assembled to the highest standards. They use advanced inspection and testing equipment to identify and correct any defects or issues before the final product is shipped.

Conclusion

PCB assembly is a critical process in the production of electronic devices. PCB assembly service providers offer a range of services to help customers design, manufacture, and assemble PCBs for various applications. When choosing a PCB assembly service provider, it is important to consider factors such as experience, expertise, quality control, turnaround time, cost, and communication.

Using a PCB assembly service provider offers several advantages over in-house assembly, including access to specialized equipment, expertise and experience, cost savings, faster turnaround times, and quality assurance. By outsourcing PCB assembly to a trusted service provider, customers can focus on their core competencies and ensure that their electronic devices are assembled to the highest standards.

FAQ

- What is the difference between through-hole and surface-mount PCB assembly?

-

Through-hole PCB assembly involves inserting component leads through holes drilled in the PCB and soldering them to pads on the opposite side. Surface-mount PCB assembly involves placing components directly on the surface of the PCB and soldering them to pads on the same side.

-

What is the minimum order quantity for PCB assembly services?

-

The minimum order quantity for PCB assembly services varies depending on the service provider and the specific services required. Some providers may offer low-volume or prototype assembly services with minimum order quantities as low as one unit, while others may require larger minimum orders for high-volume production runs.

-

How long does the PCB assembly process typically take?

-

The PCB assembly process typically takes several days to several weeks, depending on the complexity of the design, the volume of the order, and the specific services required. Prototype assembly services may have faster turnaround times, while high-volume production runs may take longer.

-

What types of components can be used in PCB assembly?

-

PCB assembly can use a wide range of electronic components, including resistors, capacitors, inductors, diodes, transistors, integrated circuits, and connectors. The specific components used will depend on the design and functionality of the electronic device being assembled.

-

How can I ensure the quality of my PCB assembly?

- To ensure the quality of your PCB assembly, choose a reputable PCB assembly service provider with a proven track record of success and expertise in the specific type of PCB assembly you require. Look for providers with robust quality control processes, such as automated optical inspections and functional testing, and ask for references and examples of previous work to ensure that they can meet your quality standards.

Leave a Reply