Introduction

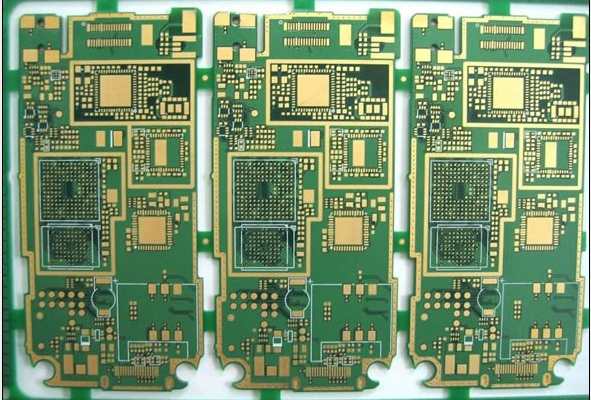

Printed circuit boards (PCBs) are essential components in nearly all modern electronics. While large electronics manufacturers can afford their own PCB fabrication facilities, startups and smaller companies often need to rely on PCB manufacturers during prototyping and early production. Finding a PCB manufacturer that can deliver high quality boards in low volumes at a reasonable cost can be a major challenge.

This guide will examine the options available for companies that need professional quality PCBs fabricated in quantities from 1 to about 1,000. We’ll look at the technologies these low volume PCB manufacturers use, how to evaluate potential suppliers, tips for getting good results, and the typical costs involved.

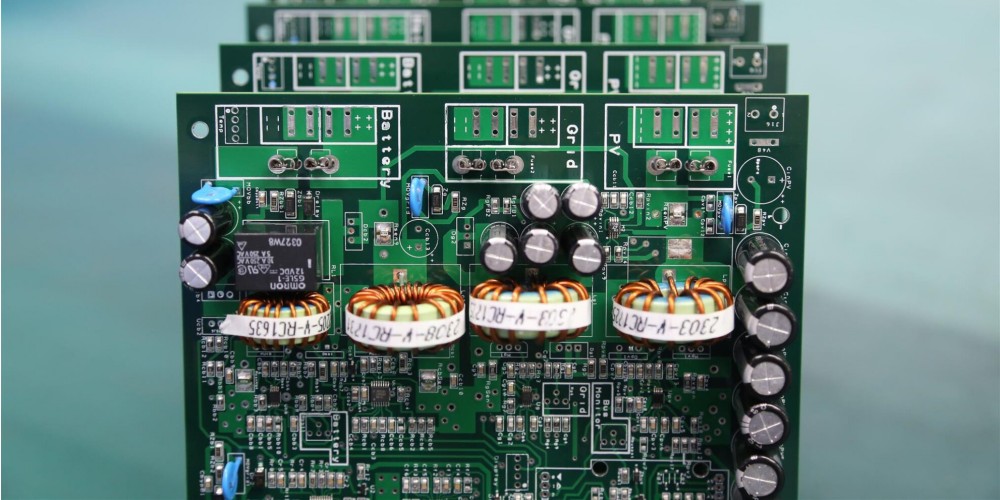

Low Volume PCB Manufacturing Technologies

There are several techniques used for making PCB prototypes and small production runs. Each has its own advantages and disadvantages.

Milling/Mechanical PCB Fabrication

PCB milling uses a mechanical bit to literally carve traces and holes out of the copper layers of a blank PCB board. While economical for very low quantities (1-5 boards), milling has limitations in trace size and spacing, can be prone to bit breakage, and does not scale well beyond 10-25 boards.

Laser Direct Imaging (LDI)

LDI uses a laser to selectively ablate (vaporize) the copper foil on a blank PCB panel to create the conductors and isolation regions. LDI can produce very fine traces and spaces similar to photolithography. It is very fast and is widely used for rapid prototyping in small volumes.

Photolithography

This traditional PCB fabrication technique uses light projected through a mask to selectively expose a photosensitive chemical resist coating on the copper layers. After developing, the unexposed copper is etched away leaving the desired conductor pattern. Photolithography allows very precise small traces and is suitable for production runs in the 10s to 1000s of boards.

Printed Electronics

An emerging technology that prints conductive and resistive inks directly onto substrates using techniques like inkjet and aerosol jet printing. Printed electronics simplifies multilayer circuits and allows flexible PCBs on plastic films. The technology is still maturing but shows promise for very low volume production.

How to Choose A Low Volume PCB Manufacturer

Several factors should be considered when selecting a low volume PCB supplier:

- Capabilities – Evaluate manufacturers based on the size PCBs they can produce, smallest trace/space they can achieve, number of layers supported, materials, finishes, etc. Ensure they can fabricate what you need.

- Quality – Check out example boards and read reviews to gauge the consistency and reliability of their boards. More expensive doesn’t always mean better quality.

- Turnaround Time – Low volume production often implies short lead times. Choose a supplier that delivers in your timeframe.

- Cost – Get quotes from several manufacturers. Be wary of prices that seem too good to be true.

- Experience – An established company with experience serving low volume customers can help avoid potential issues. Check years in business and client lists.

- Communication – Good communication helps ensure your expectations are met. Choose a company that is responsive and professional.

- Order Process – Convenient ways to upload design files and order online make the process easier. Look for order tracking and status updates.

- Location – Domestic manufacturers provide shorter lead times. International options have lower costs but longer shipping.

Tips for Success With Low Volume PCB Manufacturers

Follow these tips to get the best results when working with a low volume PCB supplier:

- Provide complete design specifications – Don’t assume the manufacturer will just know what you need. Detail board dimensions, materials, layer count, finishes, soldermask color, silkscreen, etc.

- Build a little margin into trace/space rules – For example, specify 6 mil trace/space if your design requires 8 mil. Allows for small variances in their process.

- Provide comprehensive fabrication and assembly drawings – Should include layer stackup, finish information, soldermask outlines, assembly diagrams, etc.

- Ask for a design review by the manufacturer – An experienced engineer may catch issues in your Gerber files you didn’t notice.

- Order a small number of boards for initial prototyping – Verify quality before investing in higher quantities.

- Have reasonable expectations for costs, features, and lead times – Low volume processes have inherent time/cost tradeoffs. Stay flexible.

- Maintain clear communication – Promptly respond to manufacturer requests for feedback or additional information.

- Provide feedback to the manufacturer – Let them know what’s working and areas for improvement so processes can be refined.

Costs for Low Volume PCB Production

Costs for low volume PCB production are generally higher per board than high volume production. However, competitive options are available starting under $100 for small prototype boards. Here are some typical benchmarks:

- 1-25 boards – $200 – $1500 per design. Small boards with 2-4 layers in this volume are usually $200 – $500.

- 25-100 boards – $1500 – $4000 per design. Cost per board drops rapidly in this range.

- 100-1000 boards – $3000 – $10000 per design. $10-30 per board.

- 1000+ boards – Enter high volume pricing at under $10 per board.

There are many factors that influence costs such as size, layer count, materials, and lead time. Be sure to get multiple quotes first for the volumes you need. Evaluate both domestic and international options.

Recommended Low Volume PCB Manufacturers

Based on capabilities, customer reviews and reputation, here are some top recommended low volume PCB fabricators to consider:

Domestic US Manufacturers

- Advanced Circuits – One of the largest US prototype PCB manufacturers. Excellent reputation.

- Sunstone Circuits – Leading low volume PCB supplier located in Oregon.

- Imagineering Inc – A Michigan based, quick-turn low volume PCB producer.

- Sierra Circuits – West coast fabricator with good low volume capabilities.

International Low Cost

- JLCPCB – Massive China based PCB company with low prices on small batches.

- PCBWay – Another respected Chinese manufacturer with online ordering.

- WellPCB – Specialized in prototype and small-medium volume orders.

- Elecrow – Low minimum orders and cheap PCB options.

Conclusion

Finding a PCB manufacturer that delivers professional quality boards with fast turnarounds at reasonable costs is critical when a project moves from prototyping to pilot builds. There are many low volume PCB fabricators to choose from, both domestic and overseas. Do your research to find those that best match your specific requirements. Building a relationship with a supplier that understands the needs of low volume customers can be a valuable asset.

Frequently Asked Questions

What are typical minimum order quantities for PCB manufacturing?

Typical minimum orders are:

- Prototype/testing volumes: 1-10 boards

- Low volume production: 10-25 boards

- Medium volumes: 25-100 boards

- High volume: 100+ boards

However, some manufacturers specialize in very low minimum quantities starting at just 1 or 2 boards for prototyping needs.

How long does low volume PCB manufacturing take?

Turnaround times for low quantities generally range from 24 hours up to 7-10 days. The fastest options use technologies like LDI which avoids the lengthy photolithographic processes but cost more.

What design file formats do PCB manufacturers need?

Gerber (.gbr) and drill (.drl) files are the standard for PCB manufacturing. Most also accept CAD files but may charge additional fees. Always check the required file formats before ordering.

Can I order assembled PCBs (with components) in low volumes?

Many manufacturers offer assembly services for prototypes and small batches. Lead times extend to 2-4 weeks typically and costs increase. Verify assembly capabilities before selecting a low volume PCB supplier.

What are the main quality issues to look out for?

Insufficient copper, spacing/clearance violations, annular ring violations, uneven plating, solder mask and silkscreen registration errors, and handling damage are common low volume PCB quality issues. Work with your manufacturer to identify any process improvements needed.

Leave a Reply