Introduction

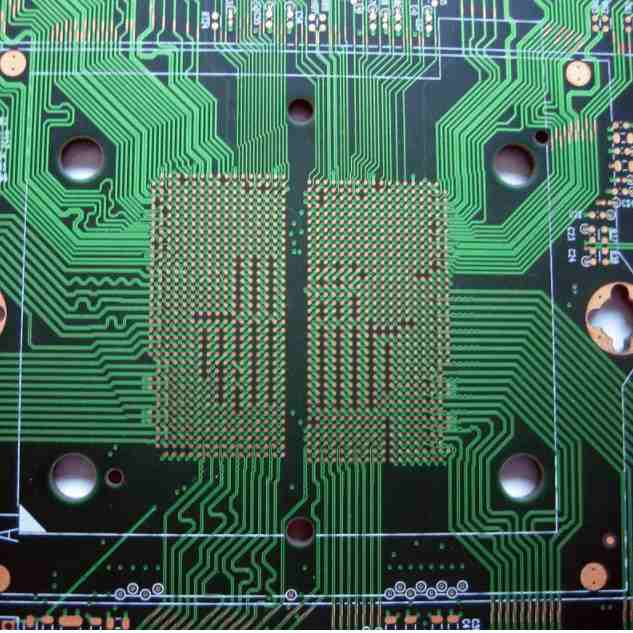

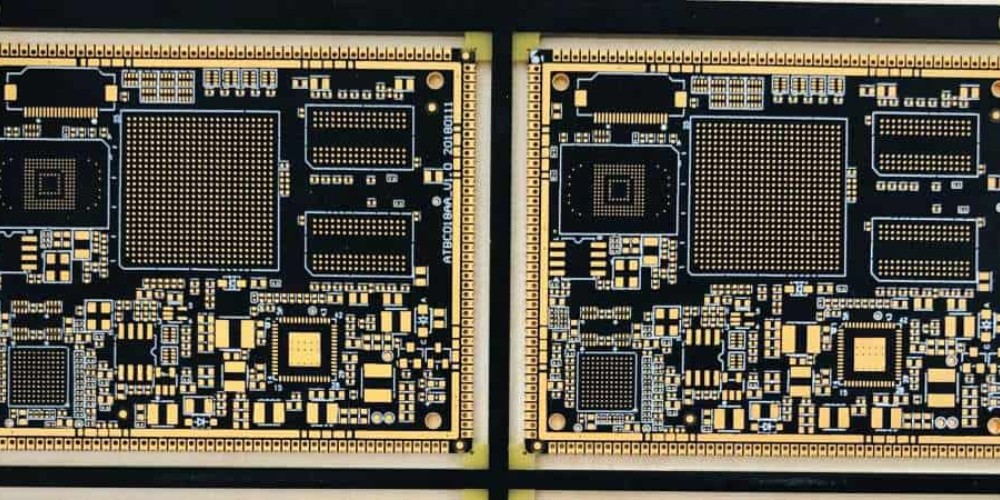

Printed circuit boards (PCBs) are an essential component of most modern electronic devices and products. They provide the foundation on which components are mounted and connected to create a functional electronic circuit. For hardware startups, makers, and hobbyists, having access to low cost PCB manufacturing can help enable rapid prototyping and small production runs.

This guide will explore the key considerations around low cost PCB production, including PCB fabrication methods, costs and lead times, design for manufacturability, and finding a suitable PCB manufacturer. With careful planning and design, it’s possible to get high quality PCBs produced in low volumes at very affordable costs.

PCB Fabrication Methods

There are several PCB fabrication processes available, each with different cost and capability tradeoffs. Here are some of the most common methods used for low volume PCB production:

Milling/Mechanical Drilling

A CNC milling machine is used to machine away copper from a copper clad PCB blank to create the desired traces, pads, and holes. While flexible for prototyping, mechanical drilling and milling becomes time consuming for higher complexity boards.

Cost: $$

Lead time: 1-5 days

Min. quantity: 1

Complexity: Low

Quality: Moderate

Chemical Etching

With chemical etching, a chemical solution is used to etch away unwanted copper from a copper clad board. A photosensitive layer acts as a mask to protect the desired copper traces.

Cost: $

Lead time: 1-3 days

Min. quantity: 1

Complexity: Moderate

Quality: Moderate

Laser Direct Imaging (LDI)

A laser beam etches the pattern directly onto a photosensitive coating on the raw PCB. The exposed areas are then chemically washed away, leaving only the desired copper traces.

Cost: $$

Lead time: 1-4 days

Min. quantity: 1

Complexity: High

Quality: Good

Photolithography

A photomask is created from the PCB design file and used to selectively expose a photoresist coating on the PCB. Exposed areas are etched away, leaving the final traces.

Cost: $$$

Lead time: 2-5 days

Min. quantity: 10-25

Complexity: Very High

Quality: Excellent

Cost and Lead Times

When using a low cost PCB manufacturer, here are some typical costs and lead times to expect:

PCB Qty | Cost per board | Lead Time —|— 1-10 | $5 – $50 | 1-4 days 10-25 | $2 – $10 | 1-5 days

25-100 | $1 – $5 | 3-7 days 100-500 | $0.50 – $2 | 5-10 days 500+ | $0.10 – $1 | 10-15 days

For very quick turnaround on a small number of boards, expect higher per board costs. Economy pricing kicks in at mid-volume orders of 100-500 boards.

Design for Manufacturability Guidelines

Here are some key design for manufacturability guidelines to follow that will help ensure your PCBs can be fabricated quickly and affordably:

- Trace/space width: Keep traces and spaces between traces greater than 6 mil (0.15mm)

- Finished copper weight: 1oz (35μm) copper allows lower cost fabrication

- Number of layers: 2 layer boards are ideal, avoid >4 layers if possible

- Minimized number of drill holes: Combine holes/pads when possible

- Standard thickness: 1.6mm is most cost effective

- Avoid cutouts: Cutouts and internal routing adds cost

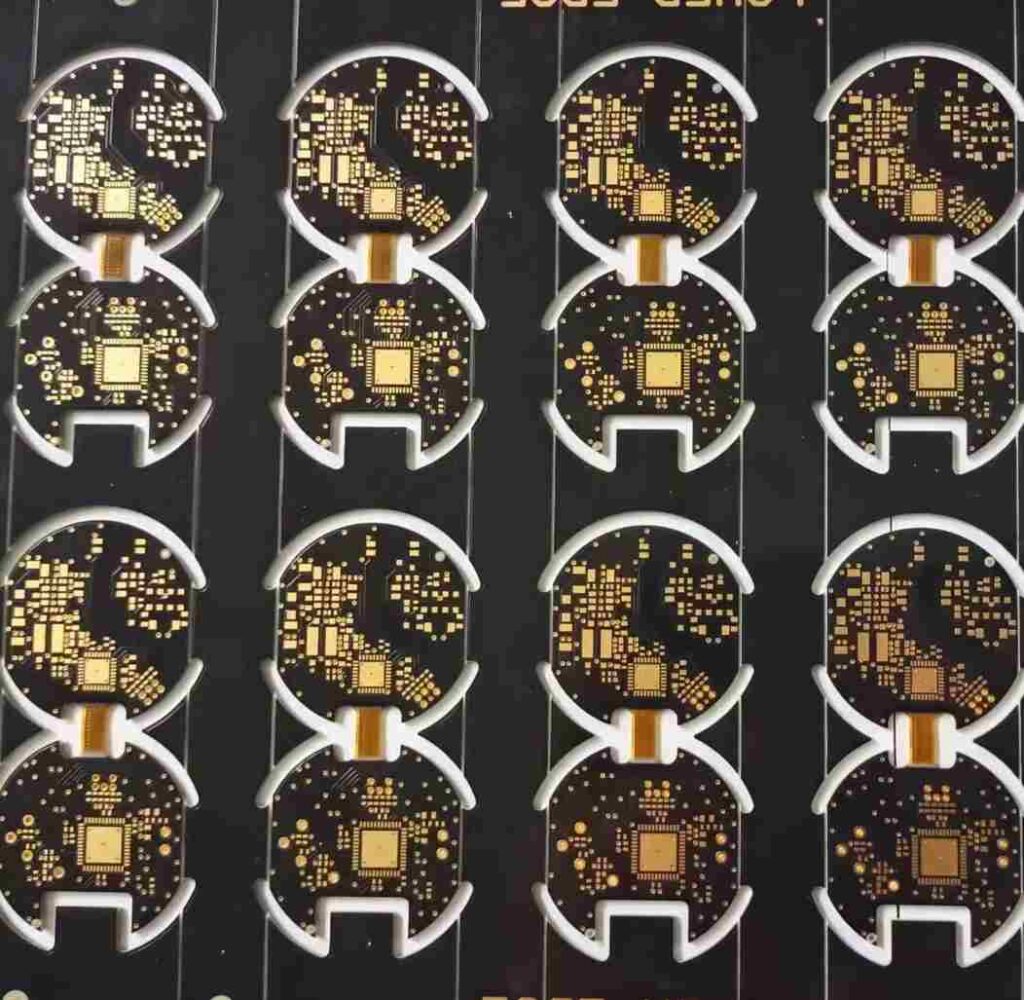

- Panelization: Panelizing multiple boards lowers cost

- Soldermask/silkscreen colors: Standard green soldermask & white silkscreen are cheaper

- Gold fingers: Avoid unnecessary gold plating

- Plated slots/holes: Minimize or avoid when possible

- Board shape: Square boards are most cost effective

Finding a Good Low Cost PCB Manufacturer

Here are some tips for identifying a suitable low cost PCB manufacturer:

- Check reviews & reputation: Search for reviews, check sites like PCBScope for ratings.

- Get quotes: Get quotes from several manufacturers, compare on cost.

- Ask about capabilities: Inquire about their fabrication capabilities and tolerances.

- Review lead times: Confirm typical lead times for your planned order quantities.

- Check quality: Ask for PCB samples and photos of previous work.

- Evaluate their design rules: Make sure their design rules work for your board.

- Test their customer service: How helpful and responsive are they to questions?

- Inspect factory certificates: Look for UL, ISO-9001, and other certifications.

- Consider location: Shipping costs may be lower with a geographically closer manufacturer.

Some examples of low cost PCB manufacturers to consider are PCBWay, JLCPCB, ALLPCB, EasyEDA, DirtyPCBs, and Smart Prototyping. Many offer online instant quoting, design rule checks, and assembly services.

Conclusion

With careful design considerations and a bit of shopping around, it’s possible to find low cost PCB manufacturers capable of producing small batches of boards at very reasonable costs. Focus on keeping board complexity low, follow design for manufacturability guidelines, and evaluate multiple manufacturers before selecting one that meets your requirements for cost, lead time, and quality.

With affordable access to PCB prototyping and small scale manufacturing, hardware innovators and entrepreneurs can turn their ideas into reality without breaking the bank.

Frequently Asked Questions

What are some tips for minimizing PCB costs?

Some tips for minimizing PCB costs include:

- Use 2 layer boards instead of 4+ layers when possible

- Minimize drill holes by combining pads/vias

- Use surface mount components instead of through-hole

- Standardize on common soldermask/silkscreen colors

- Avoid unnecessary coatings like immersion gold

- Eliminate cutouts and internal routing when feasible

- Panelize multiple boards together

- Order larger quantities to benefit from volume discounts

What design software is best for DIY PCBs?

Some popular low cost or free PCB design software options are KiCad, EasyEDA, DipTrace, and Eagle. These provide the features necessary for designing PCBs while avoiding the cost of expensive paid options. They allow export to Gerber files needed for fabrication.

Can PCB manufacturers assemble my boards as well?

Many PCB manufacturers, including low cost ones, offer PCB assembly as an additional service. They can purchase and solder components onto the boards, eliminating the need to assemble by hand. This provides convenience at the expense of some increased cost over bare PCB production.

How many PCB design rules should I follow?

It’s advisable to follow as many of the manufacturer’s design rules as possible. The more you deviate, the higher the risk of fabrication problems. Start with their minimum trace/space rules as a bare minimum. Review other rules around drill sizes, mask expansion, silkscreen, etc.

What are panelized PCBs and their benefits?

Panelizing refers to arranging multiple PCBs together on a larger panel that is sent through fabrication as one board. The individual boards are then cut or routed apart after fabrication. This lowers cost by maximizing board utilization area. It also improves consistency between boards.

Leave a Reply