Introduction

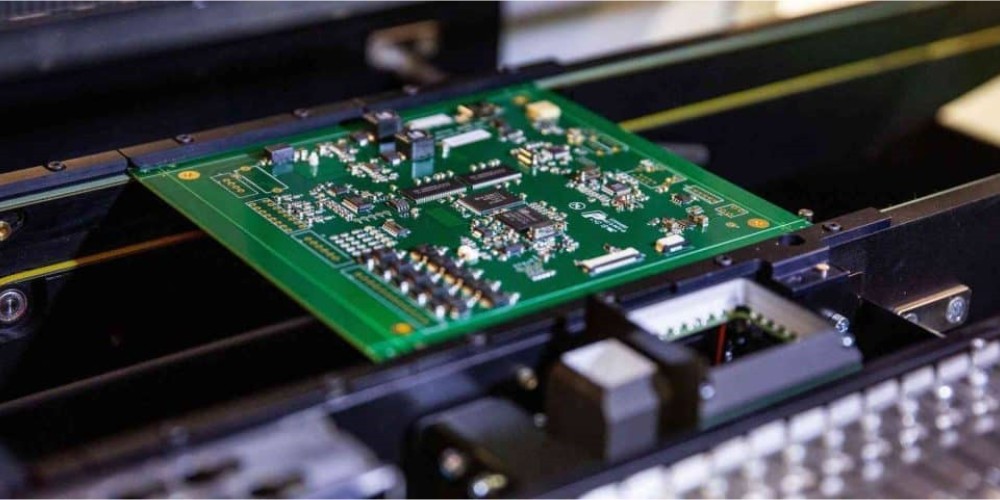

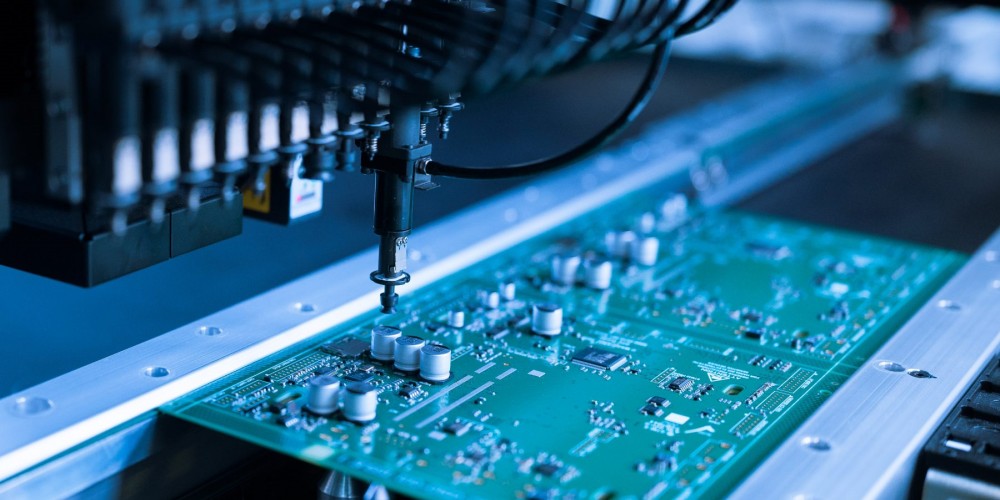

A printed circuit board (PCB) mill is a desktop CNC machine used to mill or engrave printed circuit boards. PCB mills allow circuit designers and engineers to rapidly prototype single or double sided PCBs without having to send designs out for fabrication. This enables faster design iteration and testing.

PCB mills range widely in price and capabilities. Factors that affect the cost include:

- Work area/size

- Milling precision

- Spindle speed

- Software capabilities

- Additional features

This article will provide an overview of PCB mill costs, features, and considerations when selecting a machine.

PCB Mill Cost Range

PCB mills can range from a few hundred dollars for basic hobbyist models to tens of thousands for industrial machines with large work areas and precision.

Here is an overview of the price ranges for different classes of PCB mills:

- Hobbyist – $200 to $2000

- Small work area

- Low precision

- Manual tool changing

- Prosumer – $2000 to $10,000

- Larger work area

- Higher precision

- Automatic tool changing

- Industrial – $10,000 to $50,000+

- Large work areas

- High precision

- Additional capabilities like drilling

Within each range, prices vary based on factors like work area size, spindle speed, and software capabilities. More expensive mills in each class typically have larger work areas, faster spindle speeds, and more advanced software.

Hobbyist PCB Mills

At the low end, hobbyist PCB mills can be purchased for $200 to $2000. Example models include:

- Bantam Tools PCB Milling Machine – $1900

- Voltera V-One – $2499

- LPKF ProtoMat S43 – $1990

- Othermill Pro – $2199

These mills have small work areas around 4 x 4 inches to 8 x 10 inches. They can mill basic circuit boards but have limited precision and capability. Hobbyist mills typically have manual tool changing.

The low cost makes them accessible for circuit designers to mill prototypes or small batches. But their limited capabilities may not suffice for complex or high density boards.

Prosumer PCB Mills

In the $2000 to $10,000 range are “prosumer” or professional consumer models geared for small businesses, makerspaces, and advanced hobbyists. Example models include:

- Bantam Tools PCB Pro Milling Machine – $8499

- LPKF ProtoMat S63 – $5290

- Roland Modela MDX-50 – $5995

- Othermill Pro Max – $4699

- T-Tech Quick-Circuit 7000 – $6995

These provide larger work areas of 8 x 12 inches up to 14 x 24 inches. They also offer faster spindle speeds (10,000 to 60,000 RPM), better precision, and automatic tool changing.

The expanded capabilities allow milling of more complex boards with finer features. Prosumer models can handle small scale production runs.

Industrial PCB Mills

Industrial PCB mills from $10,000 to $50,000 are found in professional PCB fabrication shops. Leading models include:

- LPKF ProtoMat S104 – $36,900

- LPKF CircuitMaster – $19,900

- Rolland Modela MDX-540 – $16,495

- AccurateCNC PCBoard Pro – $12,995

Large work areas from 20 x 30 inches up to 59 x 120 inches accommodate panel sized PCB production. High precision spindle heads allow intricate milling down to small trace sizes. Automatic tool changers support larger tool sets.

Additional capabilities like drilling holes, optical registration, and mechanical isolation provide professional grade PCB prototyping and fabrication.

Some high end industrial PCB mills cost over $50,000. For example, the LPKF ProtoLaser S4 Laser System integrates laser micromachining with milling for extremely high resolution PCB structuring down to under 10um features.

Refurbished and DIY CNC Mills

Lower cost alternatives are refurbished or DIY built desktop CNC mills adapted for PCB milling. However, these options require more expertise get going.

Refurbished hobbyist CNC mills can sometimes be found under $1000. Some makers convert general purpose CNC routers into PCB mills. And DIY CNC builds from kits or plans provide ways to obtain mills at a fraction of commercial prices.

Key Specifications and Features

When evaluating PCB mills, some key factors to consider are:

Work Envelope Size

The work envelope determines the maximum PCB size that can be milled. Standard work areas range from just a few inches for hobbyist mills up to over 4 feet for industrial models.

Common sizes are:

- 4 x 4 inches

- 6 x 8 inches

- 8 x 12 inches

- 12 x 12 inches

- 14 x 24 inches

Pick a work envelope that provides some margin beyond the maximum board dimensions needed.

Spindle Speed

Faster spindle speeds improve milling resolution and reduce machining time. Typical spindle speeds are:

- Hobbyist – 15,000 to 30,000 RPM

- Prosumer – 30,000 to 60,000 RPM

- Industrial – 60,000 to 100,000+ RPM

High speeds over 60,000 RPM are desirable for milling fine pitch components.

Resolution and Precision

The achievable precision helps determine the minimum trace sizes and spaces. Precision is affected by factors like the spindle and motion system accuracy.

Typical resolution specs are:

- Hobbyist – Around 8 mil traces

- Prosumer – Around 5 mil traces

- Industrial – Under 1 mil traces

Finer resolution allows more complex boards with dense, high speed designs.

Software

The included CAM software converts PCB design files into toolpaths for milling. Entry level software offers basic milling capabilities. More advanced options enable:

- Automatic isolation routing

- Intelligent filleting

- Panelization

- Drilling integration

- Tool libraries

- Verification simulations

- Template management

Evaluate whether the software provides the features needed for your boards.

Tool Changing

Hobbyist mills use manual tool changing which reduces production efficiency. Most prosumer and industrial mills offer automatic tool changing.

The number of tool slots indicates maximum tools available during a run. Typical capacities are:

- Hobbyist – 1 to 2

- Prosumer – 4 to 8

- Industrial – 10+

More tool slots allow creating designs with different trace widths and milling strategies in a single setup.

Dust Handling

A vacuum attachment prevents hazardous copper dust from contaminating workspaces. Automatic vacuum turn on via software integration ensures the vacuum engages only during milling.

Isolation Milling

Some advanced mills incorporate isolation routing capabilities to automatically cut out board profiles. This saves an entire manual board outline cut step.

Hole Drilling

Higher end mills provide PCB hole drilling in addition to tracing. This reduces secondary drilling operations.

Usage Considerations

Factors to think about when selecting a PCB mill include:

Scale of Use

How many boards will be produced? Hobbyist mills are suitable for very low volumes or prototyping. Prosumer models allow small scale production runs. Industrial mills are designed for volume PCB fabrication shops.

Design Complexity

What trace sizes and pitches are needed? Higher precision mills enable more intricate layouts and dense component spacing.

Throughput

For time sensitive projects, choose a mill with faster spindle speeds to reduce milling times. Production environments require maximizing uptime, so automatic tool changers are preferred.

Budget

The purchase budget impacts the range of mills to consider. Potential operating costs like tooling and maintenance should be factored in as well.

Learning Curve

Hobbyist mills are easiest to get started with. More advanced prosumer and industrial mills require greater expertise to utilize their full capabilities.

Conclusion

PCB mills range from basic hobbyist models starting around $200 to industrial mills over $50,000. Typical price ranges are:

- Hobbyist – $200 to $2000

- Prosumer – $2000 to $10,000

- Industrial – $10,000 to $50,000+

Key factors affecting cost include work area size, precision, spindle speed, tool changing, and software capabilities. Consider the scale of use, design needs, throughput, budget, and learning curve when selecting a PCB mill. With an understanding of the costs and trade-offs, designers can choose the right CNC mill for their prototyping or manufacturing needs.

FAQ

What is the cheapest PCB mill I can buy?

The cheapest new PCB mills are hobbyist desktop models in the $200 to $500 range. Examples include the Othermill, Pocket NC, and some Chinese import CNC mills. While inexpensive, these have very limited work areas around 4 x 4 inches and lower precision.

Used or DIY built mills can potentially be made for under $200, but require more expertise. Overall, expect to spend $500 to $1000 at minimum for a functional entry level PCB mill.

What features make a PCB mill expensive?

Larger work areas, faster spindle speeds, precision, advanced software, and automated features increase PCB mill costs.

For example, industrial mills over $50k integrate technologies like high speed aerostatic spindles over 100,000 RPM, precision linear motion systems, laser etching, and sophisticated CAM programming for complex professional grade boards.

What is a good starter PCB mill?

Good starter mills for around $2000 to $4000 provide a balance of capability, ease of use, and cost. Examples include the Bantam Tools PCB Milling Machine, LPKF ProtoMat S43, OtherMill Pro, and Roland Modela MDX-50.

These tabletop mills offer 6 to 8 inch work areas, 20,000 to 60,000 RPM spindle speeds, and 4 to 5 mil resolution. They allow milling basic to moderately complex boards in low volumes.

Can you use a CNC router as a PCB mill?

In some cases CNC routers, including DIY built ones, can be adapted for PCB milling. However it requires using smaller end mills and optimizing feeds and speeds. Most commercial routers lack the precision and spindle speeds of dedicated PCB mills. But a router provides a lower cost way to get started with limited capability.

Should I buy new or used PCB mill?

If on a tight budget, a used mill can provide significant cost savings. However, it usually entails lower work area and precision. Make sure used mills have acceptable spindle hours and good mechanical condition.

For best capability and warranty coverage, buying new is preferable. Startup and training support from the manufacturer is also beneficial when learning to use a new PCB mill.

Leave a Reply