Introduction

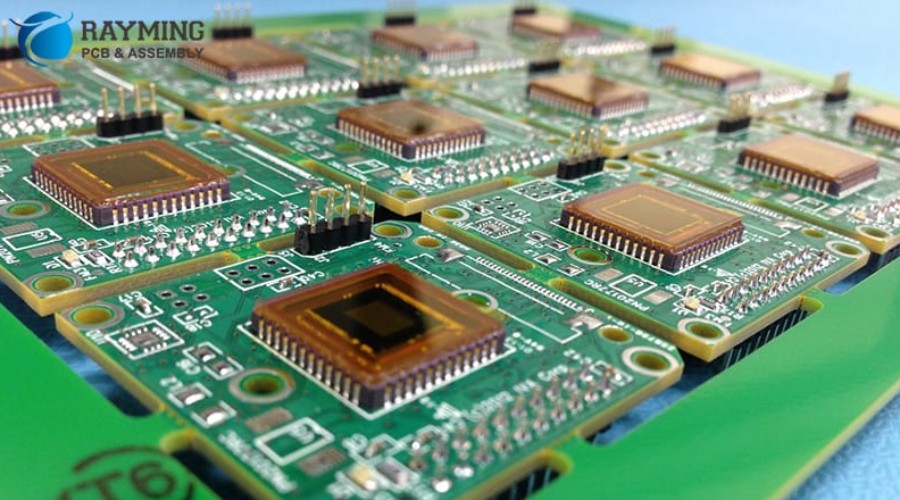

Printed circuit boards (PCBs) are essential components in virtually all electronic devices. With the growing demand for electronics, starting a PCB manufacturing business can be a lucrative opportunity. However, launching a successful PCB business requires thorough planning, significant upfront investment, and in-depth industry knowledge. This article provides a step-by-step guide to starting your own PCB manufacturing business.

Research the PCB industry

Before diving into starting your PCB business, you need to understand the industry landscape. Here are some key things to research:

- Market size and growth trends – The global PCB market was valued at $72.6 billion in 2021 and is projected to grow at a CAGR of 3.4% from 2022 to 2030. This provides strong tailwinds for new entrants.

- Customer segments – Key customer segments include consumer electronics, automotive, aerospace/defense, medical devices, and telecommunications. Each has different PCB requirements.

- Competitor analysis – Who are the major PCB manufacturers? What are their capacities, capabilities, and market shares? How can you differentiate?

- Technology trends – Emerging PCB technologies like HDI (high density interconnect), rigid-flex, and embedded components. You need to decide which capabilities to invest in.

- Regulations – Environmental regulations related to PCB manufacturing can impact your operations. Stay updated on the regulatory landscape.

Thorough market research will help you identify the most attractive product segments, capacity levels, and competitive strategies.

Determine your manufacturing capabilities

PCB manufacturing involves a complex sequence of processes. Determining your capabilities and technology investments upfront is crucial. Key considerations include:

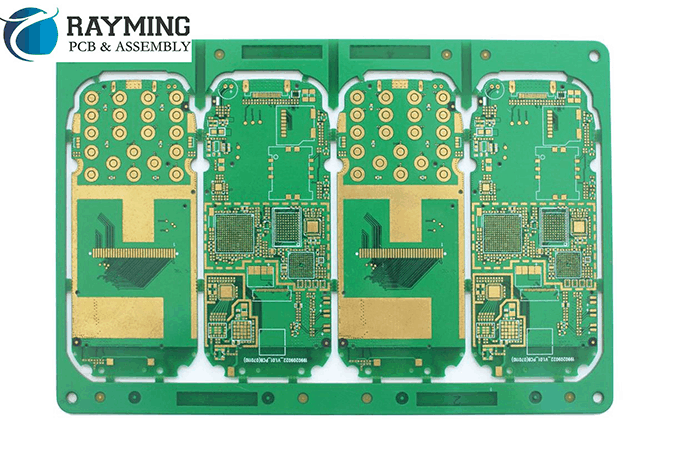

- Volume – Will you focus on high-volume, low-mix or low-volume, high-mix production? This impacts equipment choices.

- Capabilities – Simple double-sided PCBs vs. advanced HDI, flexible, and rigid-flex boards? Different capabilities need different processes.

- Technology – Will you invest in newer technologies like inkjet printing? Or start with more proven approaches? Balance innovation vs. cost.

- Quality – High reliability demands (military, aerospace) require more stringent quality control. Define your quality standards.

- Materials – FR-4 glass epoxy is the most common. But some applications require exotic materials (ceramics, Teflon, etc.)

- Certifications – Getting certified (ISO, IPC, AS9100 etc.) can open doors to lucrative markets.

Determining your manufacturing strategy is an important first step before making equipment investments.

Select PCB fabrication equipment

The core of your PCB business will be the fabrication equipment. The main equipment types include:

Imaging

- Direct imaging – eliminates the need for film positives. Modern direct imaging machines like inkjet printers offer high resolution and accuracy.

- Exposure units – traditional contact exposure units using UV light and film masks to transfer images onto boards. Lower cost than direct imaging.

Etching

- Wet chemical etching – inexpensive but involves handling large volumes of harsh chemicals.

- Dry etching – plasma or laser etching is more environmentally friendly but requires higher capital investment.

Surface finishing

- Pumice scrubbing – prepares the PCB surface for subsequent plating processes. Usually manual or semi-automated.

- Desmear/etchback – removes resin smear after drilling and prepares surfaces for metallization. Uses wet chemicals or plasma.

- Hole metallization – electroless copper and direct metallization processes coat the drilling holes walls prior to electrolytic plating.

Drilling

- Mechanical drilling – traditional drilling using bits. Multiple drills required to handle different hole sizes.

- Laser drilling – fast and accurate but involves higher machine costs.

Lamination

- Hydraulic hot presses – applies pressure and heat to bond laminate layers. Standard in most PCB factories.

- Vacuum lamination – achieves better thickness uniformity but requires more expensive equipment.

Testing

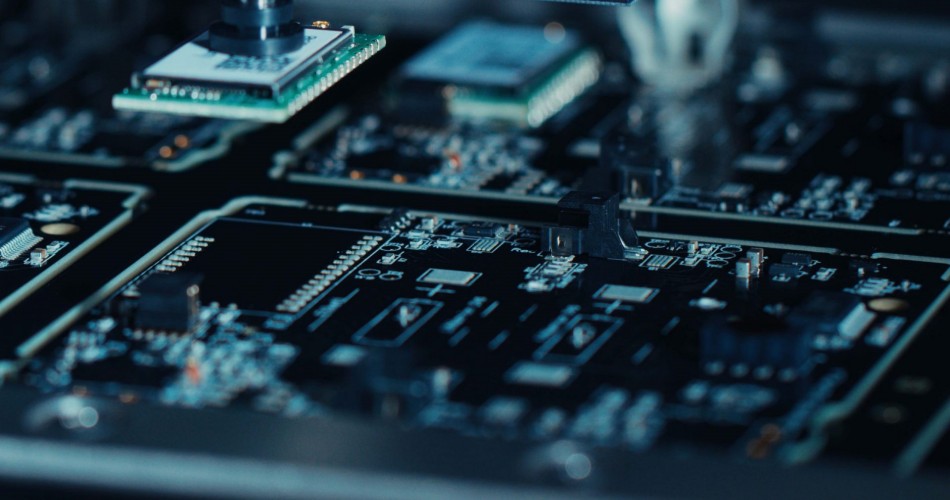

- AOI – automated optical inspection checks for defects and quality errors. Essential for process control.

- Flying probe – tests electrical connectivity and isolates faults.

- ICT – in-circuit testing verifies functioning of completed boards.

Prioritize equipment investments based on your Target capabilities, production volumes, and capital budget. Buying used equipment can also reduce initial costs.

Major Equipment for a PCB Fabrication Facility

| Equipment | Purpose |

|---|---|

| Imaging Machines | Transfer circuit patterns onto boards |

| Etching Equipment | Removes copper from unmasked areas |

| Drilling Machines | Create holes for vias and component mounting |

| Lamination Presses | Bonds together etched layers |

| Surface Treatment | Cleans and finishes boards |

| Testing/Inspection | Verifies quality and function |

Secure a facility

You need an appropriate facility to house your PCB fabrication equipment and operations:

- Space – Allow for equipment, material storage, and workflow. Aim for a larger rather than smaller facility if planning for growth.

- Zoning – Make sure the location is zoned for light industrial/manufacturing use.

- Infrastructure – Stable power supply, water, compressed air, ventilation for the equipment. May require facility upgrades.

- Environment – Strictly control humidity and temperature for consistent PCB fabrication. May need dedicated cooling or HVAC.

- Utilities – Calculate required electricity load. Etching and electroplating require significant power.

- Safety – Include chemical storage rooms, fire suppression systems, and waste management. Follow safety codes.

- Location – Proximity to customers, supply chain partners, and skilled workforce. Weigh logistics costs.

Leasing an existing facility with infrastructure in place may be faster and cheaper than constructing your own building. Make sure the facility aligns with your current and future needs.

Obtain financing

Starting a PCB manufacturing business requires significant upfront capital investment. The major costs include:

- Machinery purchases – likely the largest capital expense. Budget millions for a fully equipped fabrication line.

- Facility acquisition/lease – purchase, construction, or long-term lease.

- Facility upgrades – may be required for industrial zoned buildings

- Raw materials inventory – build up initial inventory of laminates, etchants, etc.

- Working capital – cover payroll, utilities, and other expenses during ramp-up to breakeven. Assume 3-6 months.

Since most equipment must be purchased prior to generating revenue, you need access to capital. Financing options include:

- Self-funding – tapping into personal savings and assets.

- Business loans – bank financing using assets as collateral. SBA-backed loans are one common option.

- Private investors – sell equity in the business in exchange for startup capital.

- Crowdfunding – pool smaller investments from a larger group of investors.

A combination of debt and equity financing may be required to raise the full amount. Create detailed financial projections to determine how much funding you need and potential returns for investors.

Hire an experienced team

There are numerous specialized skills involved in PCB manufacturing. Building a talented team is essential for success. Key roles you need to fill include:

- Operations manager – oversee fabrication workflows, equipment, and processes. PCB manufacturing experience is a must.

- Process engineers – optimize fabrication lines and address technical issues. Background in chemistry a plus.

- Quality manager – implement quality control processes and standards.

- Equipment technicians – maintain and troubleshoot machinery. Electrical/mechanical skills required.

- Sourcing manager – manage raw material inventory and supplier relationships.

- Sales and marketing – business development connecting with customers and driving sales.

For skilled technical roles, hiring from established PCB manufacturers can provide a talent pipeline. Offer attractive pay and equity incentives to build an expert team.

Implement robust processes

With the proper equipment and team, you need to implement repeatable processes for consistent, high-quality PCB production:

- Process documentation – detailed standard operating procedures for each fabrication step. Ensure consistency.

- Quality management – implement rigorous testing and inspection at multiple process stages.

- LIMS – a laboratory information management system to digitally track work in progress.

- Change management – control process for equipment adjustments or new product introductions.

- Training – ensure all employees understand the processes and their individual roles. Conduct ongoing skills development.

- Continuous improvement – use data to identify bottlenecks or quality issues. Optimize based on lessons learned.

- Certifications – get certified to quality standards like ISO 9001 to validate your rigorous processes.

Well-defined processes are the foundation for meeting your quality and volume commitments to customers. This takes time and discipline to implement.

Offer differentiated services

Competing on price alone is not sustainable long-term. Offer differentiated services to stand out versus larger incumbents:

- Quick turnaround – focus on quick-turn prototyping to complement, not compete with high-volume players.

- Custom capabilities – develop specialized expertise in complex board technologies that interest key customers.

- Supply chain integration – provide additional assembly, test, enclosures, etc. to deliver full product solutions.

- Design support – assist customers early in optimizing board layouts for manufacturability.

- Customer service – provide exceptional service with fast response times and technical support.

- Sustainability – promote your environmental commitments like chemical recycling.

Establishing your niche and aligning closely with customer needs can help overcome competition from larger players. Keep innovating your capabilities and services over time.

Market and sell effectively

Once you have established production capabilities, ramping up sales is critical:

- Website – showcase your capabilities, services, and customer success stories. Optimize SEO.

- Tradeshows – exhibit at major electronics industry events to connect with prospects.

- Sales team – hire experienced salespeople who can connect with your target customer segments.

- Marketing campaigns – leverage email, social media, and pay-per-click ads to reach new prospects. Promote your differentiation.

- Partnerships – partner with CMs, OEMs, and design firms to be included in their supply chain.

- Pricing – offer competitive pricing, but avoid price wars with higher volume manufacturers.

- Certifications – obtain relevant certifications that open doors for government and defense work.

For early customers, offer discounts or free prototypes to gain momentum with customer references. Ongoing marketing drives vital pipeline growth and utilization of your capacity investments.

Frequently Asked Questions

What are the major costs involved in starting a PCB manufacturing business?

The major costs include machinery purchases, facility acquisition/lease, facility upgrades, initial raw material inventory, and working capital during the pre-revenue ramp-up period. Total startup costs easily run into the millions for a fully equipped PCB fabrication line. Significant upfront capital is required.

What are important factors in choosing a facility location?

Key factors include sufficient space, proper zoning, availability of infrastructure and utilities to support equipment loads, temperature/humidity control, safety considerations for chemical storage and waste management, and proximity to target customers, suppliers, and skilled workforce.

What certifications help a new PCB manufacturing business gain credibility?

Obtaining quality certifications like ISO 9001 demonstrates adherence to rigorous quality systems. Manufacturing certifications like IPC help indicate your capabilities meet industry standards. Compliance to ITAR regulations enables work for aerospace/defense customers. Environmental certifications highlight sustainability.

Should new PCB manufacturing businesses focus on high-volume production?

For startup PCB fabricators with limited capital, trying to compete on high volumes with established offshore players is very difficult. A better strategy is to focus on quick-turn prototyping and low-to-medium volume production of more complex boards where you can differentiate. Gain capabilities and scale over time.

How can PCB manufacturers market themselves effectively to gain new customers?

A multifaceted strategy works best. This includes SEO optimized website, exhibiting at tradeshows, email/social media marketing, PPC ads, sales team outreach, partnerships, and offering discounts or free prototypes for early adopters. PR and content marketing also help demonstrate expertise.

Leave a Reply