Introduction

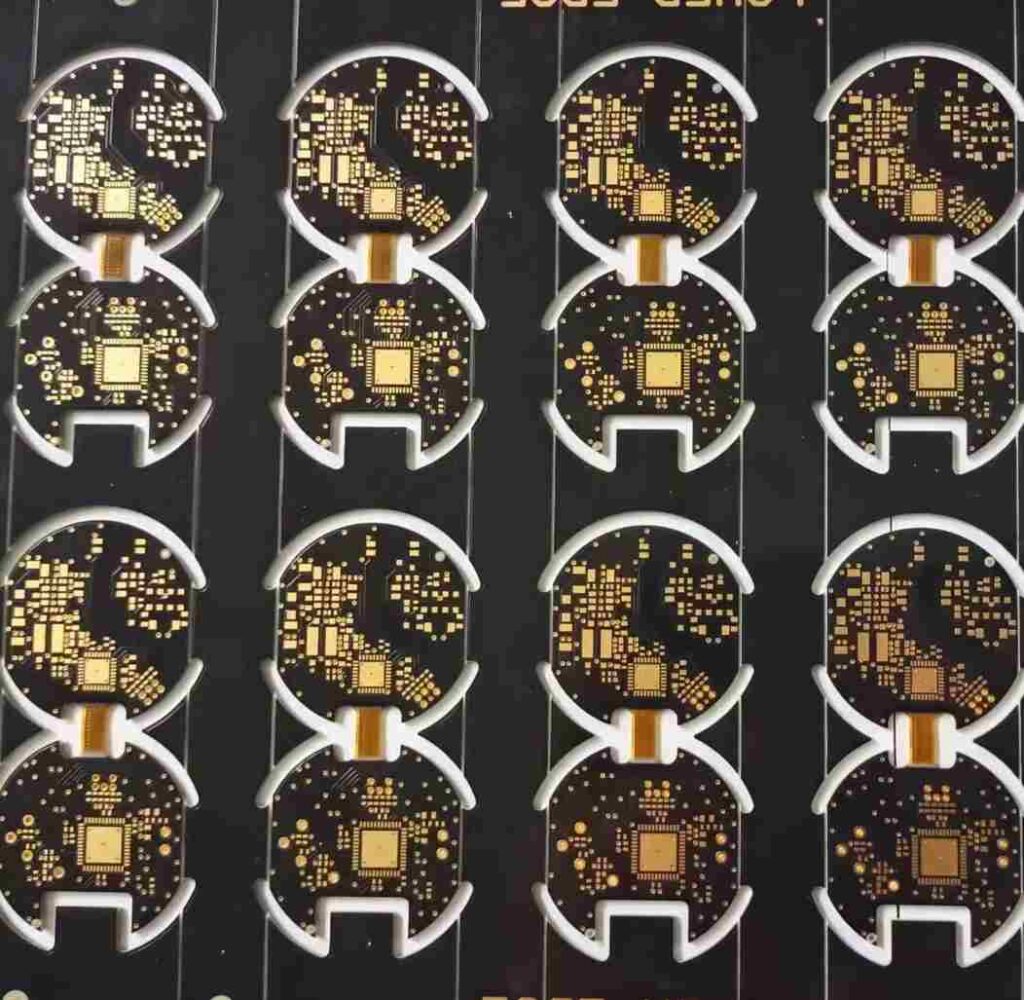

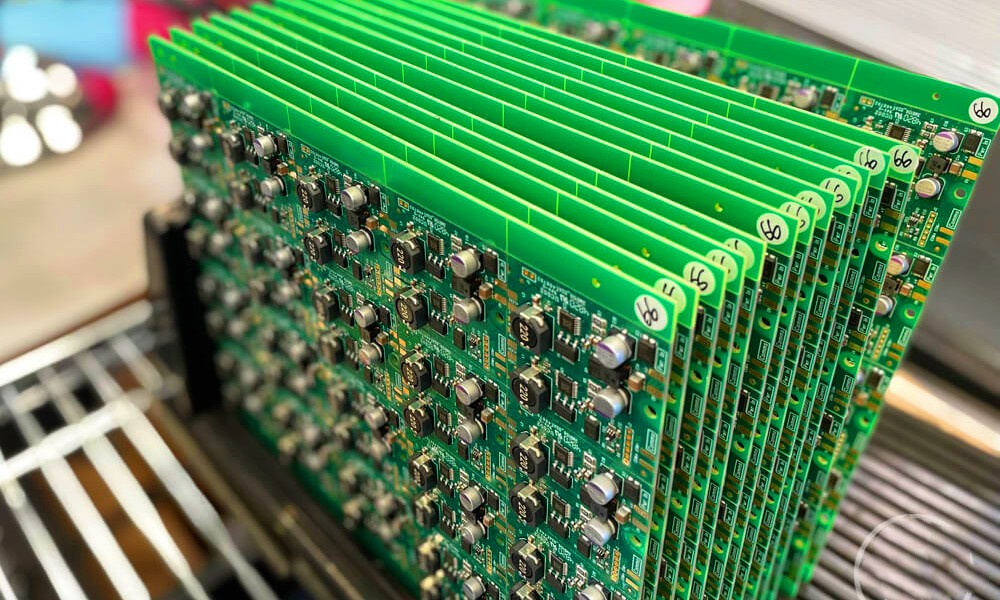

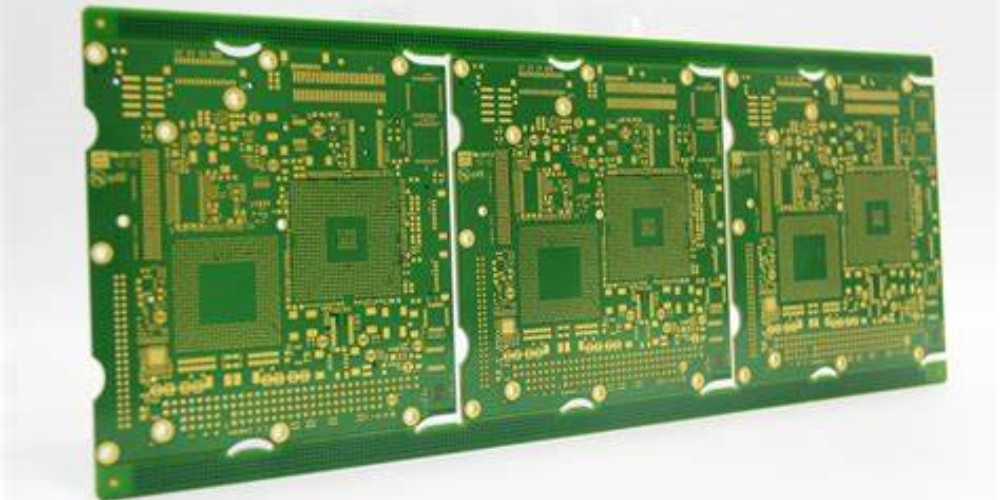

FR4, also known as flame retardant 4, is a grade of glass-reinforced epoxy laminate material that is commonly used for making printed circuit boards (PCBs). With its good mechanical strength, electrical insulation properties and heat resistance, FR4 has become the most popular material for rigid PCBs.

Asia has emerged as the leading manufacturing hub for PCBs globally. Several manufacturers in China, Taiwan and other Asian countries specialize in the production of high-quality FR4 laminates and prepregs. This article provides an overview of some of the top FR4 manufacturers in Asia.

Major FR4 Manufacturers in Asia

China

- Shengyi Technology Co. Ltd.

- Kingboard Laminates Holdings Ltd.

- Shanghai Nanya Copper Clad Laminate Co. Ltd.

- Guangdong Chaohua Technology Co. Ltd.

- Elite Material Co. Ltd.

Taiwan

- Unimicron Technology Corp.

- Nan Ya Plastics Corp.

- TUC Industrial Co. Ltd.

- Ventec International Group Co. Ltd.

South Korea

- Kukdo Chemical Co. Ltd.

- Jongwook F&C Co. Ltd.

Japan

- Panasonic Corp.

- Hitachi Chemical Co. Ltd.

- Nikkan Industries Co. Ltd.

Thailand

- Rayong Advanced Polymer & Tooling Co. Ltd.

- Thai Laminate Manufacturer Co. Ltd.

Malaysia

- SH E&E Solutions Sdn. Bhd.

- Incline Technology Sdn. Bhd.

Types of FR4 Materials Offered

The major types of FR4 materials produced by manufacturers include:

- FR4 High Tg Laminates – With glass transition temperature >170°C, these laminates are suitable for lead-free soldering.

- Halogen-free FR4 Laminates – These eco-friendly laminates do not contain brominated flame retardants.

- High Frequency FR4 Materials – Used for RF/microwave applications with low loss tangent.

- High Thermal Conductivity FR4 – Designed for good heat dissipation in electronic devices.

- Flexible FR4 – Enable flexible PCB applications.

- CEM-1 and CEM-3 Compliant FR4 – Meet IPC standards for PCB fabrication.

Comparison of Properties of FR4 Materials Offered by Major Manufacturers

| Manufacturer | Dielectric Constant | Loss Tangent | Tg | Thermal Conductivity |

|---|---|---|---|---|

| Elite Material | 4.4-4.6 | 0.02 | 170°C | 0.29 W/mK |

| Ventec International | 4.2-4.6 | 0.016-0.022 | 170°C | 0.3 W/mK |

| Nan Ya Plastics | 4.4-4.7 | 0.02 | 180°C | 0.25 W/mK |

| Unimicron | 4.2-4.5 | 0.015-0.025 | 180°C | 0.3 W/mK |

| Kukdo Chemical | 4.4-4.7 | 0.02 | 170°C | 0.3 W/mK |

As can be seen from the table, the FR4 laminates from leading manufacturers offer comparable electrical and thermal performance parameters. Companies like Ventec and Nan Ya also offer high Tg variants specially designed for lead-free soldering applications.

Applications of FR4 Materials

Some of the common applications of FR4 laminates include:

- Consumer electronics – Mobile phones, laptops, tablets, etc.

- Computer and peripherals – Motherboards, graphics cards, hard drives.

- Automotive electronics – Navigation systems, engine control units.

- Industrial electronics – PLCs, process control devices.

- Communication systems – 5G infrastructure, routers, switches.

- Aerospace and military – Avionics, radars, weapons systems.

The high mechanical strength makes FR4 suitable for both rigid and flexible PCB applications. The flame retardant properties enable safe operation in electrical devices. Manufacturers also offer high frequency and thermal management variants to meet requirements of specific applications.

Selecting the Right FR4 Manufacturer

Here are some tips on selecting the right FR4 material manufacturer:

- Opt for established manufacturers that are ISO 9001 and IATF 16949 certified. This ensures product quality.

- Check if they can offer a wide range of FR4 variants for different applications.

- Look for manufactures that can provide suitable prepregs, copper foils etc. for complete PCB fabrication.

- Evaluate technical capabilities like line width, layer count, hole size etc.

- Review quality certifications, test reports and sample orders before large volume procurement.

- Choose manufactures that can provide customization of FR4 properties like Tg, dielectric constant based on your PCB design needs.

- Ensure the manufacturer has good customer support and sales engineers who can guide you in selecting the optimal FR4 material.

- Check lead times and inventory availability to avoid delays in your production schedule.

By partnering with the right FR4 material supplier, PCB manufacturers can develop boards that meet the electrical, thermal and mechanical performance needs for modern electronic devices.

Frequently Asked Questions on FR4 Materials

Q: What is the difference between FR4 and FR5 materials?

A: FR5 has a higher glass transition temperature (>220°C) compared to FR4 and can withstand higher temperature during lead-free soldering processes. It has improved thermal performance but also higher material costs.

Q: Can FR4 be used for RF and microwave PCBs?

A: Yes, there are specialized high frequency FR4 materials with low loss tangents below 0.005 that make them suitable for RF and microwave applications up to 15 GHz.

Q: Is FR4 suitable for flexible PCBs?

A: Manufacturers do offer flexible FR4 materials that can be used to fabricate flex PCBs, however polyimide is more commonly used as it has better flexural endurance.

Q: What is the typical thickness of FR4 laminate sheets?

A: FR4 is typically supplied in thickness ranging from 0.2 mm to 3 mm. Common prepreg thicknesses are in the range of 50μm to 150μm.

Q: What is the typical copper thickness used on FR4 PCBs?

A: 1 oz (35μm) copper foils are commonly used on FR4 based PCBs. But some applications require thicker 2 oz or 3 oz copper up to 105μm thickness.

Leave a Reply