Introduction

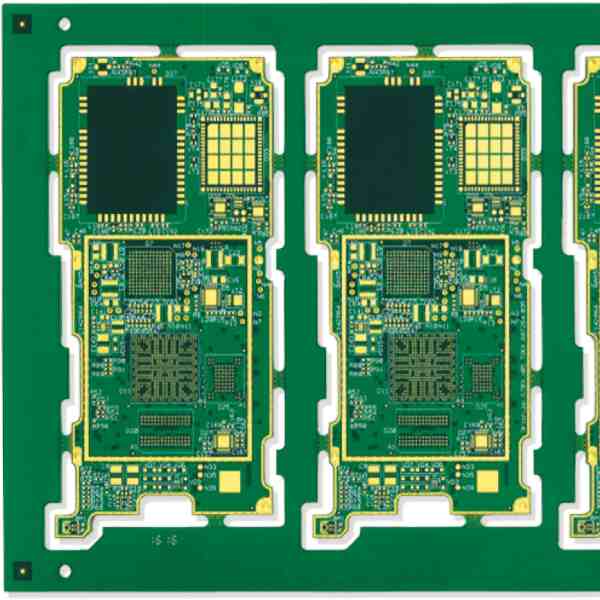

For hardware engineers and designers, being able to quickly iterate on prototypes is critical during the development process. Waiting weeks or months for each prototype PCB (printed circuit board) fabrication can significantly slow down a project. This is where fast turn prototype PCB services come in. These services promise fabrication times ranging from 24 hours to a few days, allowing you to test your design, make modifications, and order the next rev far more rapidly.

In this article, we’ll cover everything you need to know about fast turn prototype PCBs including:

- Benefits of fast turnaround

- Technology enabling rapid fabrication

- What to look for in a fast turn PCB provider

- Design considerations for quick-turn boards

- Costs and lead times

- When to use standard vs fast turn

- Review of top fast turn PCB manufacturers

With the right guidelines, you can easily leverage fast turn PCBs to accelerate your development cycles and get innovative products to market faster.

Benefits of Fast Turnaround Prototype PCBs

For prototyping stages, fast turn PCBs provide many advantages over standard turn times (5-15 days):

- Faster design validation – Test whether your circuit works and make improvements in less time.

- Rapid design iterations – Iterate faster through multiple revisions and refinements.

- Accelerate development – Overall product development moves forward quicker.

- Earlier testing – Start compatibility, performance, and reliability testing sooner.

- Faster feedback – Get feedback from colleagues and testers more rapidly.

- Quicker go-to-market – Products can launch earlier than competitors.

- Respond to emergencies – Urgent design modifications can be fabricated in 1-2 days.

For non-commercial projects, students, hobbyists, and researchers can also benefit from the ability to quickly try out ideas or build proofs-of-concept without long fabrication lead times.

Technologies Enabling Fast Prototype PCB Production

Several advances in PCB fabrication technology now allow manufacturers to turn around prototype boards in just 24-48 hours:

- Direct imaging – Exposes photoresist on boards directly without films. Eliminates film image transfer step.

- Laser direct imaging (LDI) – Uses a laser to directly expose boards, enabling faster imaging.

- Automated optical inspection – Automated cameras quickly validate trace position, alignment, etc.

- Improved processing – Technologies like panel plating allow parallel processing of PCBs.

- On-demand board production – Minimal upfront batch setup enables quick fabrication from electronic files.

- Streamlined supply chain – Inventory management systems for components & materials enable rapid order fulfillment.

By leveraging these technologies while optimizing their internal processes, some PCB manufacturers can now rapidly produce prototype PCBs from customer designs in just 1-2 days.

What to Look for in a Fast Turn PCB Manufacturer

If you need fast turnaround on prototype PCB fabrication, here are key criteria to evaluate potential manufacturers:

- Turnaround time – Look for 24, 48, or 72 hour turn capabilities. Be sure to clarify if that includes shipping time.

- Domestic vs. overseas – Local manufacturers generally provide faster turns but may have higher minimums and costs.

- Order cut-off time – The daily order deadline to receive your boards within the standard lead time.

- Shipping options – Whether standard, priority, or overnight shipping is offered.

- Quality – Having rapid turns is useless if board quality suffers. Ensure they meet your requirements.

- Design capabilities – Can they fabricate the layer count, materials, features, etc. you need?

- Prototyping experience – Look for expertise in low-to-mid volume prototype boards.

- Customer support – Responsive sales engineers and customer service can facilitate a smooth fast turn experience.

- Online capabilities – Instant quoting, design uploads, order tracking and status notifications help speed the process.

- NPI services – Some offer expanded services like assembly, testing, enclosures to provide a complete prototype solution.

Design Considerations for Fast Turn PCBs

While fast turn manufacturers use advanced processes, there are still some PCB design considerations to ensure your boards can be fabricated quickly and accurately:

- Avoid intricate details or tolerances – Stick to more relaxed trace/space and tolerances suitable for rapid processing.

- Minimize panelization – Panelizing your PCB design takes more time. Ordering individual boards expedites fabrication.

- Use larger finished sizes – Smaller boards take more precision and time. Larger sizes up to 9”x9” are easier for fast turn.

- Avoid heavy copper – Thicker 2 oz or 3 oz copper requires additional steps and can impact lead time.

- Watch trace densities – Dense interconnects are possible but can be more challenging to image rapidly.

- Minimize layer count – While some processes support 20+ layers, simpler 4-6 layer designs are most optimal for fast turnaround.

By keeping your prototype PCB layout simple and avoiding complexity, you’ll get the quickest fabrication. As processes improve, fast turn services can accommodate more advanced designs. But when in doubt, simpler is better.

Cost Considerations for Fast Turn PCB Prototypes

In general, fast-turn fabrication comes at a premium cost over standard prototyping:

- Smaller lot charges per board – May be 2-4X higher than volume pricing.

- Higher NRE costs – Extra for specialized services and rush engineering support.

- Priority material and processing fees – Premium pricing for prioritized production and supply chain support.

- Faster shipping fees – Overnight shipping can add significant cost over standard methods.

However, the ability to get prototypes in 24-48 hours rather than 2-4 weeks is extremely valuable for accelerating development. And for lower volume needs, total spend is still reasonable. For urgent iterations or modifications even at higher volumes, fast turn PCB services can still provide a big competitive advantage.

When to Use Standard vs. Fast Turnaround PCBs

Here are some guidelines on when to utilize standard prototyping vs. fast turn services:

Standard Turnaround

- Early conceptual prototypes

- Designs still in flux

- Cost sensitive projects

- Testing different implementation options

- Low volumes

Fast Turnaround

- Finalizing design ahead of launch

- Design revisions from prototype feedback

- Urgent fixes found during testing

- Accelerated projects with tight deadlines

- Low-to-mid volume production runs

Evaluate the priorities and tradeoffs for each design to decide whether standard or fast turn PCB fabrication aligns better with your specific prototyping needs.

Top Fast Turn Prototype PCB Manufacturers

Many PCB manufacturers now offer some level of expedited prototyping services. Here are some of the top fast turn PCB fabricators used by hardware developers and engineers:

PCBWay

- 24 hour turnaround

- Streamlined online ordering

- Rigid and flex PCB manufacturing

- Assembly and other extended services

Advanced Circuits

- 48 hour standard service

- 4-layer board capability

- US-based manufacturing

- Prototyping and NPI services

Sierra Circuits

- 24-hour turn for under 150 boards

- Design for manufacturability checks

- Domestic and offshore options

- Standard 5-day turn for larger quantities

Sunstone Circuits

- 24-hour express turnaround

- Design reviews within 2hrs

- Circuits up to 6 layers

- Online DFM analysis

JLCPCB

- SLA options down to 24 hrs

- Budget oriented service

- Maximum 6 layers

- Additional rapid prototyping services

Conclusion

Fast turn prototyping enables PCB designers and engineers to iterate faster and accelerate development for maximum competitiveness. By leveraging advanced PCB fabrication processes and technology, select manufacturers can produce quality boards from concept to hand in just 24-48 hours. While fast turn comes with increased costs, the ability to test concepts quickly and work through revisions rapidly provides huge time-to-market advantages. With the guidelines provided, you can now find the right partner and approach to start benefiting from ultra-fast PCB prototype turns.

FQA:

Q: What are the key benefits of fast turn prototype PCBs?

A: The main benefits are the ability to validate designs faster, iterate quicker through revisions, accelerate overall development, start testing sooner, get feedback rapidly, and reduce time-to-market.

Q: What is the typical cost premium for fast turn vs. standard prototype PCBs?

A: In general, fast turn fabrication costs 2-4X as much as standard prototyping services due to smaller lot charges per board, higher NRE costs, priority fees, and faster shipping.

Q: What is the main technology enabling 24-48 hour PCB prototyping?

A: Direct imaging through laser technologies is one of the key innovations allowing PCB manufacturers to image boards without films rapidly for fast turnaround.

Q: What design factors should be considered for quick-turn PCBs?

A: Simpler designs with relaxed tolerances, fewer layers, larger sizes, lower densities, and avoiding panelization helps enable the quickest fast turn fabrication.

Q: Are there advantages of using domestic vs. international PCB manufacturers for fast turns?

A: Domestic manufacturers generally offer quicker turns and improved communication but have higher costs. Overseas options provide budget friendly alternatives but longer lead times.

Leave a Reply