PCB Blog

-

Read more: Till what resolution of components can be printed with the Rayming stencil-mate?

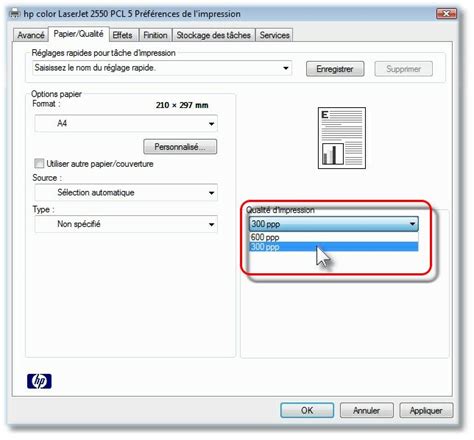

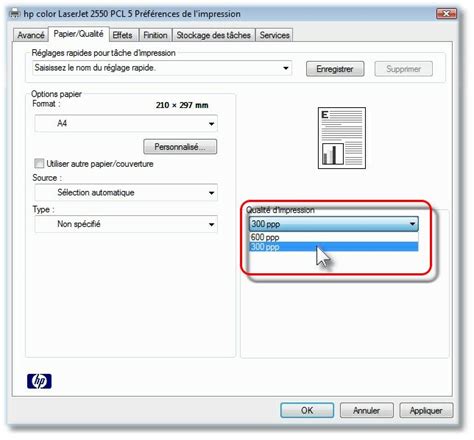

Read more: Till what resolution of components can be printed with the Rayming stencil-mate?Introduction to Printing Resolution Printing resolution is a crucial factor when it comes to the quality and precision of printed electronic components. In the world of electronics manufacturing, the ability to print fine details and small components accurately is essential for creating high-performance devices. The Rayming stencil-mate is a popular […]

-

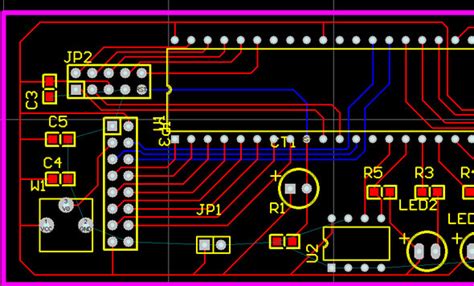

Copper Distribution on a Panel

Posted by

–

Read more: Copper Distribution on a Panel

Read more: Copper Distribution on a PanelWhy is Copper Distribution Important? Copper distribution on a panel is critical for several reasons: Electrical Conductivity: Copper is an excellent conductor of electricity, making it ideal for creating conductive paths on PCBs. Even distribution ensures that electrical signals can travel efficiently and reliably throughout the panel. Heat Dissipation: Copper […]

-

Embedded World 2024 – Your Personal Ticket

Posted by

–

Read more: Embedded World 2024 – Your Personal Ticket

Read more: Embedded World 2024 – Your Personal TicketIntroduction to Embedded World Embedded World is the leading international trade fair for embedded systems, showcasing the latest trends, innovations, and technologies in the industry. The event takes place annually in Nuremberg, Germany, attracting thousands of exhibitors, visitors, and experts from around the globe. Embedded World 2024 promises to be […]

-

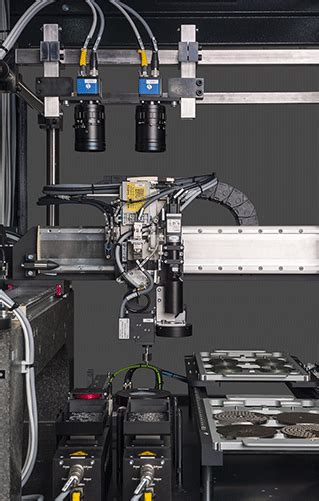

Read more: Placer camera-assisted manual pick and place machine

Read more: Placer camera-assisted manual pick and place machineIntroduction to Placer-assisted pick-and-place In the world of electronics manufacturing, pick-and-place machines have become an essential tool for accurately and efficiently placing components onto printed circuit boards (PCBs). These machines have revolutionized the industry by automating the process of component placement, significantly reducing human error and increasing production speeds. However, […]

-

Rayming-reflow-pilot door open

Posted by

–

Read more: Rayming-reflow-pilot door open

Read more: Rayming-reflow-pilot door openWhat is the Rayming-reflow-pilot? The Rayming-reflow-pilot is an advanced reflow soldering machine that is widely used in the electronics manufacturing industry. It is designed to precisely control the temperature profile during the soldering process, ensuring optimal results for various types of PCBs and components. Key features of the Rayming-reflow-pilot include: […]

-

Read more: 10 Rules for Better Data – Avoid PCB Design Issues

Read more: 10 Rules for Better Data – Avoid PCB Design IssuesIntroduction to PCB Design Rules Printed circuit board (PCB) design is a complex process that requires careful planning and attention to detail to ensure the final product functions as intended. To help avoid common issues and create high-quality PCBs, it’s important to follow a set of established design rules. In […]

-

How do you prevent Solder Escape/Wick?

Posted by

–

Read more: How do you prevent Solder Escape/Wick?

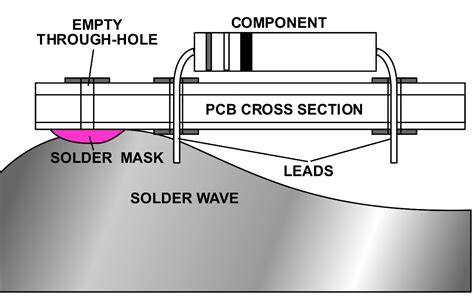

Read more: How do you prevent Solder Escape/Wick?Understanding Solder Escape What is Solder Escape? Solder escape, also known as Solder Wicking, is a phenomenon that occurs during the soldering process when molten solder is unintentionally drawn away from the intended connection point. Instead of forming a strong and reliable solder joint, the solder travels along component leads, […]

-

Read more: Tips & Tricks: Avoiding Solder Escape/Wick during Reflow

Read more: Tips & Tricks: Avoiding Solder Escape/Wick during ReflowWhat is Solder Escape? Solder escape, also known as solder wicking, is a common issue in Electronic Assembly where molten solder flows or “wicks” away from the intended joint, along the component lead or PCB trace. This can result in insufficient solder at the joint, leading to poor electrical connections, […]

-

Edge Connectors with Gold Surface

Posted by

–

Read more: Edge Connectors with Gold Surface

Read more: Edge Connectors with Gold SurfaceIntroduction to Gold-Plated Edge Connectors Gold-plated edge connectors are a type of electrical connector commonly used in various electronic devices, such as computers, telecommunications equipment, and industrial machinery. These connectors are designed to provide a reliable and efficient means of connecting printed circuit boards (PCBs) to other components or systems. […]

-

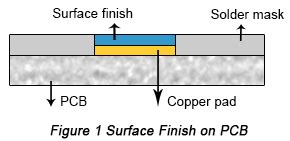

Selecting the Right Surface Finish for Your PCB

Posted by

–

Read more: Selecting the Right Surface Finish for Your PCB

Read more: Selecting the Right Surface Finish for Your PCBWhat is a PCB Surface Finish? A PCB surface finish is a coating applied to the exposed copper traces and pads on a printed circuit board. Its primary purpose is to protect the copper from oxidation and corrosion, which can occur due to exposure to air, moisture, and other environmental […]