Introduction

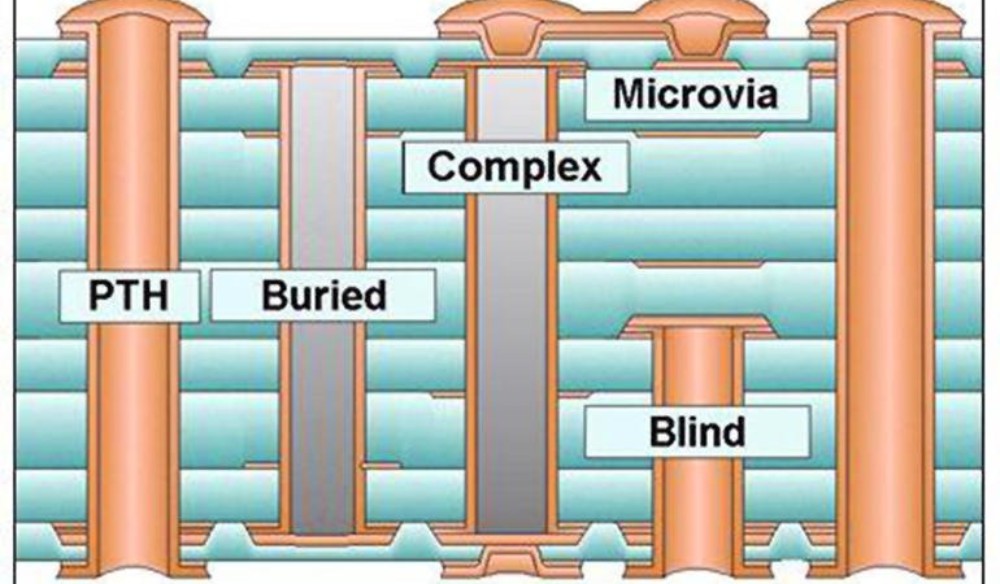

In printed circuit board (PCB) design, vias are plated-through holes that connect traces between layers. Vias can be classified as through vias or blind/buried vias. Through vias span the entire height of the PCB, connecting layers from the top to the bottom. Blind or buried vias, on the other hand, connect only between adjacent layers without spanning the full height.

An important question that often comes up is – are blind vias filled? The answer depends on the manufacturing process and intended application. In this article, we will explore what blind vias are, whether they need to be filled, the filling process, and the pros and cons of filled versus non-filled blind vias.

What are Blind Vias?

Blind vias are holes that connect one or more internal layers of a PCB without spanning the full height. They enable interlayer connections without using up surface space for through vias. Blind vias are so named because they are blind-ended on one side.

Some key characteristics of blind vias:

- Connect two or more internal layers

- Do not span the full PCB height

- Often used for high-density designs

- Allow routing between layers with minimal surface usage

Blind vias should not be confused with buried vias, which are blind on both sides and do not connect to any outer layer.

Do Blind Vias Need to be Filled?

Filling blind vias is an optional step – they can be left unfilled based on the design and manufacturing requirements. Here are some guidelines on when filling is recommended:

- High frequency or high-speed designs: Filling eliminates air gaps which could cause impedance mismatches. This allows maintaining a consistent dielectric.

- Vias under a BGA package: Filling provides mechanical support under the BGA pads. Prevents pad cratering during soldering.

- Dense boards with many vias: Filling reduces chances of solder wicking into the vias during assembly.

- Sensitive components nearby: Filling prevents solder paste from entering vias, which could cause shorts.

- Structural integrity: Filled vias mean less air gaps and a more robust board.

Filling is not necessary in some cases:

- Vias only connecting 2 layers: Air provides sufficient insulation between layers.

- Simple or low-density boards: No major benefits from filling blind vias.

- Non plated vias: There are no plated barrel surfaces for solder wicking or shorts.

So in summary, filling blind vias is recommended for high-speed, high-density, or complex boards to get most design benefits. But it is not strictly required in all cases.

How are Blind Vias Filled?

There are two main techniques used by PCB manufacturers to fill blind vias during fabrication:

1. Plugging

Plugging involves inserting a solid material into the blind via to fill it up. Typical plugging materials include:

- Epoxy plugs: Epoxy resin is dispensed into the via and cured. Provides mechanical stability.

- Conductive ink plugs: Silver or copper-filled ink is used when electrical conductivity is needed.

- Solder plugs: Applied by printing solder paste or pumping in molten solder. Good conductivity.

Epoxy is the most common blind via plugging material. Conductive ink or solder provides electrical contact but can increase cost.

2. Tenting

Tenting uses soldermask, silkscreen, or other coatings to seal the via on one side. The tenting layer adheres to the internal barrel surface, essentially capping off the via.

Tenting has some advantages over plugging:

- No additional process steps or materials needed

- Prevents solder wicking on tented side

- Allows probe access from open side

- Lower cost compared to epoxy or conductive plugs

The main disadvantage of tenting is lack of mechanical support compared to solid plugs. So plugging is preferred for vias under BGAs or in high-stress areas.

Pros and Cons of Filling Blind Vias

Here is a comparison of the relative advantages and disadvantages of filled vs. non-filled blind vias:

Filled Blind Vias

Pros

- Eliminates air gaps, provides electrical and mechanical stability

- Prevents solder wicking into via barrel

- Reduces chances of shorts between layers

- Provides support under components like BGAs

- Allows consistent dielectric for controlled impedance

Cons

- Additional process steps increase fabrication time and cost

- Conductive filling can cause shorts between layers

- Plugs may fall out or create voids due to thermal expansion mismatch

- Not easily repairable or accessible once filled

Non-Filled Blind Vias

Pros

- Simple and low-cost process, no filling steps required

- Allows access to internal layers for debugging or probing

- Voids from thermal mismatch not a concern

- Permits airflow for convection cooling

Cons

- Air gaps may cause impedance mismatches

- Allows solder wicking into via during assembly

- No mechanical support under components

- Can allow solder paste bridging between layers

In summary, filling provides better electrical, thermal, and structural performance while non-filled offers lower cost and ease of rework. The tradeoffs must be evaluated for each design based on priorities.

Key Takeaways

- Blind vias connect between internal PCB layers without spanning full board height

- Filling blind vias is recommended for high-speed, RF, or dense designs to eliminate air gaps

- Common filling methods include epoxy plugging, conductive ink, solder, and tenting

- Filled vias provide stability but increase cost; non-filled offers lower cost and access

- Whether to fill depends on design requirements – it is not always strictly necessary

Blind Via FAQs

Here are some frequently asked questions about blind vias and filling:

Q: Can blind vias be left unfilled?

A: Yes, blind vias can be left unfilled. It is not mandatory to fill them. Based on the design, non-filled blind vias are acceptable.

Q: Do filled blind vias improve conductivity?

A: Not necessarily. Filling with conductive ink or solder does increase conductivity. But epoxy plugs do not – they just provide mechanical stability.

Q: Does filling blind vias increase cost?

A: Yes, the additional process steps required for filling blind vias does increase fabrication cost compared to leaving them unfilled.

Q: Can solder wick into filled blind vias?

A: Filling blind vias is specifically done to prevent solder wicking. Epoxy or tenting seals the via barrel from solder access.

Q: What is the most popular blind via filling method?

A: Epoxy plugging is the most common and cost-effective filling technique. Tenting provides a lower-cost alternative.

Leave a Reply